Water Temp Sensor: How to Test it for Reliable Performance?

Learn how to test a water temp sensor like a pro. Ensure system reliability with our step-by-step guide and expert tips.

- Why Testing a Water Temp Sensor Matters

- Tools Needed to Test a Water Temp Sensor

- Step-by-Step Guide: How to Test Water Temp Sensor

- 1. Visual Inspection

- 2. Resistance Test (Using a Multimeter)

- 3. Voltage Test (For Active Sensors)

- 4. Compare with Reference Data

- Common Issues & Troubleshooting

- When to Replace a Water Temp Sensor

- Why Choose DXM for Water Temp Sensor?

- FAQs

- Q: How often should I test my water temp sensors?

- Q: Can I test a water temp sensor without a multimeter?

- Q: What’s the typical lifespan of a water temp sensor?

Knowing how to test water temp sensor is essential for maintaining accurate temperature regulation in automotive, industrial, and HVAC systems. A malfunctioning water temp sensor can lead to inaccurate readings, engine overheating, or system shutdowns. Regular testing ensures consistent performance and prevents costly repairs. This guide will walk you through the steps on how to test water temp sensor effectively, helping you avoid system failures and maintain optimal sensor functionality.

Why Testing a Water Temp Sensor Matters

Water temp sensors are integral to systems that depend on accurate temperature control. Testing your water temp sensors regularly is essential for maintaining the efficiency of these systems. If left unchecked, a malfunctioning sensor can lead to numerous problems:

- Engine Overheating: If the water temp sensor provides inaccurate readings, it may cause the engine to overheat, risking damage to other components.

- Poor Fuel Efficiency: An unreliable sensor can impact the vehicle's fuel efficiency, resulting in higher operational costs.

- False Temperature Readings: Incorrect readings from a faulty sensor may mislead the system into making wrong adjustments, leading to system malfunctions.

- System Errors in Industrial Controls: In industrial settings, water temp sensors play a vital role in controlling machinery. Faulty sensors can trigger system errors, leading to downtime.

To avoid these costly consequences, it is crucial to understand how to test water temp sensor. Regular testing allows for early detection of faults and prevents unplanned downtimes.

Tools Needed to Test a Water Temp Sensor

Before you start testing your water temp sensors, ensure you have the following tools on hand:

- Digital Multimeter: This tool is essential for measuring resistance and voltage, which are key indicators of a sensor's health.

- Thermometer: A thermometer will serve as a reference point to check if the sensor is functioning correctly under varying temperature conditions.

- Hot Water Source: A hot water source is needed to simulate real-world operating conditions for the sensor during testing.

- Wiring Diagram: In case you're dealing with a complex system, a wiring diagram will help ensure proper connections during the test.

Step-by-Step Guide: How to Test Water Temp Sensor

1. Visual Inspection

The first step in testing any sensor is a thorough visual inspection. This allows you to identify potential issues such as:

- Corrosion or Damage: Check the sensor body for signs of wear, corrosion, or any other form of damage that could impact performance.

- Loose or Frayed Wiring: Inspect the wiring for any signs of wear or loose connections, which can lead to poor signal transmission.

- Contaminants: Ensure that the sensor housing is free from dirt, dust, or any contaminants that may affect the sensor’s function.

2. Resistance Test (Using a Multimeter)

The majority of water temp sensors operate using thermistors, which change their resistance based on temperature. Here’s how to test resistance:

- Disconnect the Sensor: First, disconnect the sensor from the system to ensure no interference during testing.

- Set the Multimeter to Resistance Mode: Place your multimeter in resistance (Ω) mode.

- Measure Resistance at Room Temperature: Measure the resistance of the sensor at room temperature and compare it with the manufacturer's specifications. If the resistance is off, it could indicate a faulty sensor.

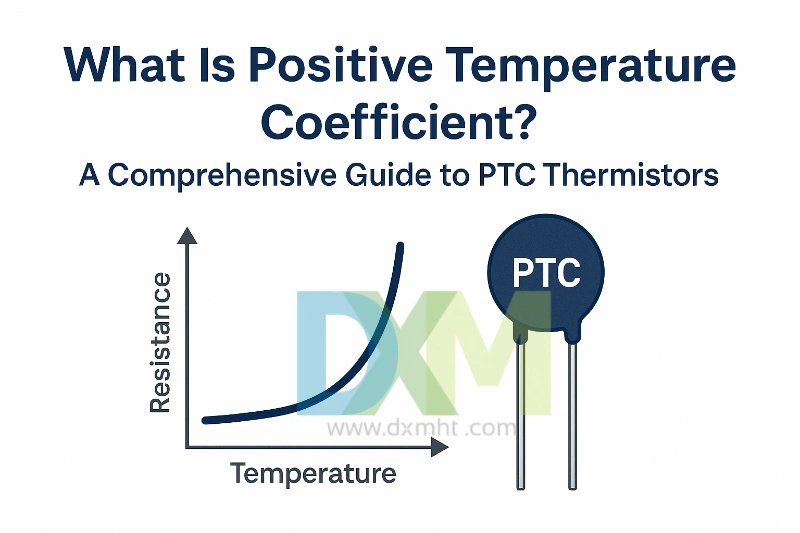

- Heat the Sensor: Place the sensor in hot water and monitor the resistance. For an NTC (Negative Temperature Coefficient) thermistor, resistance should drop as the temperature increases, while a PTC (Positive Temperature Coefficient) thermistor should show an increase in resistance with temperature.

Expected Result: The resistance should change predictably based on temperature. If not, the sensors may be malfunctioning.

3. Voltage Test (For Active Sensors)

Some water temp sensor uses voltage signals instead of resistance changes to communicate temperature data. Here’s how to test this sensor:

- Reconnect the Sensors: Reconnect the sensors to their power source to measure the voltage output.

- Set the Multimeter to DC Voltage: Ensure your multimeter is set to measure DC voltage.

- Measure the Voltage Output: Measure the voltage output from the sensors as they heat up. The voltage should increase or decrease depending on the sensors type.

Expected Result: The output voltage should change as the temperature varies, following a predictable pattern.

4. Compare with Reference Data

Finally, cross-check your readings with the sensor’s datasheet. This will help you determine if the readings are within acceptable ranges. If your readings deviate significantly, the water temp sensor may need to be replaced.

Common Issues & Troubleshooting

If you encounter the following issues while testing your water temp sensor, troubleshooting is necessary:

- No Resistance Change: This could indicate that the sensors are dead and needs replacing.

- Erratic Readings: If the readings fluctuate unpredictably, it could be a wiring issue or a sign that the sensors are faulty.

- Slow Response Time: If the sensors react too slowly, they may have contaminants or aging thermistors.

When to Replace a Water Temp Sensor

There are several signs that indicate it's time to replace your sensor:

- The readings are inconsistent or unreliable.

- There is visible physical damage to the sensors.

- The resistance or voltage readings don't match the manufacturer's specifications.

Why Choose DXM for Water Temp Sensor?

With over 29 years of expertise in sensors technology, DXM produces high-precision water temp sensors for automotive, industrial, and consumer electronics. Our ISO 9001:2008-certified manufacturing process guarantees reliability and performance. DXM’s sensors are designed to meet the highest standards of quality, ensuring optimal performance in any environment. Choose DXM for durable, high-accuracy water temp sensors that deliver consistent results.

Need a durable, high-accuracy water temp sensor? Contact DXM today for industry-leading solutions.

FAQs

Q: How often should I test my water temp sensors?

A: It’s recommended to test your water temp sensors annually or whenever performance issues arise.

Q: Can I test a water temp sensor without a multimeter?

A: No. A multimeter is essential for performing accurate resistance and voltage checks.

Q: What’s the typical lifespan of a water temp sensor?

A: Water temp sensors typically last between 5 to 10 years, depending on the operating conditions.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

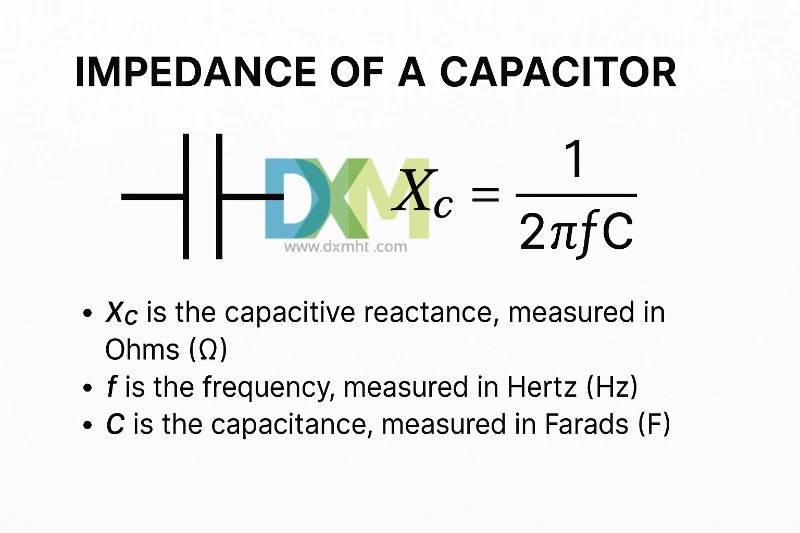

How to Find Impedance of a Capacitor: Guide for Professionals

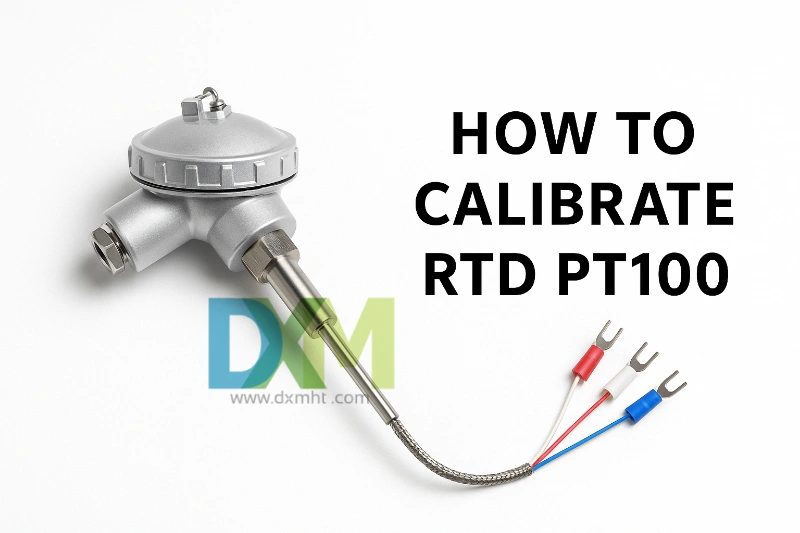

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Positive Temperature Coefficient Heater: An Essential Guide of PTC Heater

What is an Electronic Ballast PTC Thermistor? Insights from DXM.

Price and Payment

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

Logistics

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

Customized Services

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd