how to calibrate rtd pt100?

Learn how to calibrate RTD PT100 sensors accurately with DXM's expert guide. This article covers step-by-step procedures to ensure precise temperature measurement and reliable performance for your RTDs PT100 devices. Optimize your calibration process today with DXM.

- Why Calibration is Non-Negotiable for Your RTD PT100

- Understanding the Fundamentals of an RTD PT100

- When is it Time to Calibrate Your RTD PT100?

- Essential Equipment for How to Calibrate RTD PT100

- Key Methods for How to Calibrate RTD PT100

- 1. The Ice Point Method (0°C Calibration)

- Procedure:

- 2. Comparison Calibration

- Using a Dry Block Calibrator:

- Using a Stirred Liquid Bath:

- Step-by-Step Guide: How to Calibrate RTD PT100

- Common Challenges and Best Practices for RTD PT100 Calibration

- Maintaining Your Calibrated RTD PT100

- Conclusion: The DXM Advantage in Precision Temperature Sensing

In the world of precise temperature measurement, understanding rtd pt100 sensors and mastering how to calibrate rtd pt100 is paramount for professionals across various industries. At DXM, we recognize that accurate temperature data is not just a preference; it’s a fundamental requirement for operational efficiency, safety, and product quality. This comprehensive guide is designed to equip our fellow thermistor industry professionals with the knowledge and best practices needed to ensure their temperature measurements are consistently reliable.

Why Calibration is Non-Negotiable for Your RTD PT100

The integrity of your temperature data hinges on the accuracy of your sensors. Even the most robust rtd pt100 can experience drift over time due to factors such as thermal cycling, mechanical stress, or exposure to harsh environments. Regular calibration ensures that your rtds pt100 continue to provide readings that are within specified tolerances. This isn't merely a best practice; it's often a regulatory requirement, safeguarding process control, minimizing waste, and ensuring the safety of personnel and equipment. For any critical application, the consistent performance of an rtd pt100 is vital.

Understanding the Fundamentals of an RTD PT100

Before delving into calibration techniques, let's briefly review what makes an rtd pt100 a cornerstone in temperature sensing. An rtd pt100, or Resistance Temperature Detector, operates on the principle that the electrical resistance of a metal changes predictably with temperature. Specifically, a PT100 sensor has a resistance of 100 ohms at 0°C. This linear and highly repeatable relationship makes the rtds pt100 incredibly stable and accurate temperature sensors.

Different configurations of the rtds pt100 are available: 2-wire, 3-wire, and 4-wire. Each type addresses the challenge of lead wire resistance, which can significantly impact accuracy, especially in longer runs. A 4-wire rtd pt100 offers the highest accuracy by completely compensating for lead wire resistance, making it the preferred choice for high-precision applications. Understanding these nuances is crucial when you consider how to calibrate your rtds pt100 effectively.

When is it Time to Calibrate Your RTD PT100?

Determining the optimal calibration frequency for your rtd pt100 involves several considerations:

- New Installation: Every new rtd pt100 should be calibrated before its first use to establish a baseline.

- Regular Intervals: Industry standards and internal quality systems often dictate annual or semi-annual calibration for an rtd pt100.

- After Significant Events: If rtds pt100 have been subjected to mechanical shock, extreme temperatures outside its operating range, or significant power surges, recalibration is essential.

- Questionable Readings: Any erratic or suspect temperature readings from your rtds pt100 should prompt immediate recalibration.

- Before Critical Measurements: For applications where accuracy is paramount, calibrating your rtds pt100 directly before use is a sound practice.

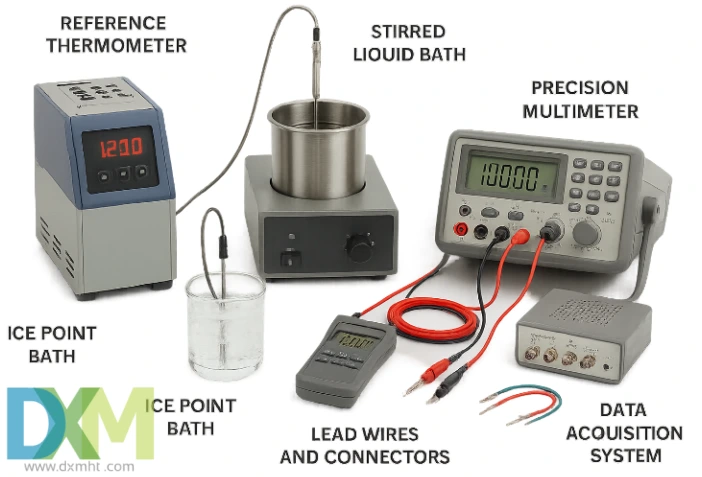

Essential Equipment for How to Calibrate RTD PT100

To perform accurate calibration on an rtd pt100, you'll need specialized equipment that provides precise and stable temperature environments, alongside accurate measurement tools:

- Reference Thermometer: This is a highly accurate, calibrated sensor (often another precision rtd pt100, thermistor, or platinum resistance thermometer) used as the standard against which your unit under test (UUT) is compared. Its calibration must be traceable to national or international standards.

- Temperature Source:

- Dry Block Calibrator: Ideal for field and lab use, these provide a stable, uniform temperature in a metal block well. They are clean and offer rapid heating/cooling.

- Stirred Liquid Bath: Offers superior temperature uniformity, especially for calibrating multiple sensors or irregularly shaped probes. Water, silicone oil, or fluidized sand baths are common.

- Ice Point Bath: A simple, highly accurate method for establishing a 0°C reference point. Crucial for understanding the baseline performance of your rtds pt100.

- Precision Multimeter or RTD Calibrator: Used to measure the resistance of the rtds pt100 at various temperatures. A dedicated rtd pt100 calibrator can directly display temperature readings based on the sensor's resistance.

- Lead Wires and Connectors: High-quality, low-resistance wires appropriate for the rtds pt100 configuration (2, 3, or 4-wire) are critical to minimize measurement errors.

- Data Acquisition System (Optional): For automated logging of temperature readings, enhancing efficiency and reducing manual error when calibrating an rtd pt100.

-

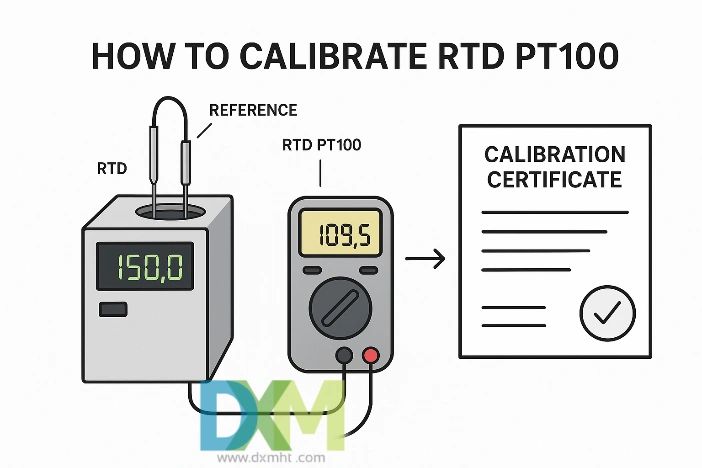

Key Methods for How to Calibrate RTD PT100

We typically employ two primary methods for calibrating an rtd pt100:

1. The Ice Point Method (0°C Calibration)

This is a foundational single-point calibration check, perfect for quickly verifying the 0°C reading of an rtd pt100. It leverages the precise melting point of pure ice at atmospheric pressure.

Procedure:

- Fill an insulated flask with crushed ice made from distilled water.

- Add enough distilled water to just saturate the ice. Stir thoroughly to ensure a uniform ice-water mixture.

- Immerse the rtd pt100 sensor and the reference thermometer to an adequate depth (typically 15-20 times the diameter of the probe). Ensure the sensing elements are well within the ice bath.

- Allow sufficient time for both the rtds pt100 and the reference to stabilize at 0°C (usually 15-20 minutes).

- Record the resistance reading from your rtds pt100. It should ideally read 100.00 ohms. Compare it to the reference.

2. Comparison Calibration

This method involves placing the rtds pt100 (UUT) alongside a calibrated reference thermometer in a stable temperature source and comparing their readings across a range of temperatures. This is the most common and versatile method for calibrating an rtd pt100.

Using a Dry Block Calibrator:

Dry block calibrators are excellent for calibrating an rtd pt100 in a controlled environment. They offer portability and quick temperature changes.

- Insert the rtds pt100 and the reference probes into the wells of the dry block calibrator. Ensure good thermal contact.

- Set the dry block to the desired calibration temperature point.

- Allow ample time for both sensors to stabilize at the set temperature. This is crucial for accurate readings for your rtds pt100.

- Record the resistance reading of the rtd pt100 and the temperature reading of the reference.

- Repeat this process for several temperature points across the intended operating range of your rtds pt100 (e.g., -20°C, 0°C, 50°C, 100°C).

Using a Stirred Liquid Bath:

Liquid baths provide superior temperature uniformity, making them ideal for high-accuracy calibration of an rtd pt100, especially when calibrating multiple sensors simultaneously.

- Fill the bath with an appropriate liquid (e.g., water for 0-100°C, silicone oil for higher temperatures).

- Place the rtds pt100 and reference probe into the bath, ensuring their sensing elements are close together and fully immersed.

- Set the bath to the desired temperature point and activate the stirrer to ensure uniform temperature distribution.

- Wait for stabilization, then record the readings from both the rtds pt100 and the reference.

- Repeat for multiple points, just as with the dry block.

Multipoint calibration is highly recommended over single-point checks, as it allows you to characterize the behavior of your rtds pt100 across its full operating range, identifying any non-linearities or discrepancies. This comprehensive approach ensures that your rtd pt100 provides accurate measurements at all critical temperatures.

Step-by-Step Guide: How to Calibrate RTD PT100

Follow these steps for a structured approach to calibrating your rtd pt100:

-

- Preparation:

- Clean your rtd pt100 and ensure it's free of any contaminants.

- Verify all electrical connections are secure and correct (especially for 3-wire or 4-wire configurations to properly compensate for lead wire resistance).

- Ensure all calibration equipment is powered on and warmed up.

- Setup the Calibration System:

- Place the rtds pt100 (UUT) and the calibrated reference thermometer in your chosen temperature source (dry block or liquid bath).

- Ensure adequate immersion depth for both sensors. Generally, the sensing element should be immersed at least 15-20 times its diameter to minimize stem conduction errors for the rtds pt100.

- Establish Stable Temperature Points:

- Set the temperature source to your first calibration point.

- Allow sufficient time for the temperature to stabilize. This is critical. For an rtd pt100, stabilization can take 10-30 minutes, depending on the thermal mass.

- Record Readings:

- Once stable, simultaneously record the reading from the reference thermometer and the resistance (or temperature) reading from your rtds pt100.

- Repeat this process for each subsequent calibration point across the desired range. We recommend taking at least three readings at each point once stable.

- Calculate Errors and Adjustments:

- Compare the readings of your rtds pt100 against the reference. Calculate the deviation (error) at each point.

- If the errors exceed acceptable tolerances, determine the necessary correction factors or recalibration coefficients. For some systems, direct offset adjustments can be made.

- Documentation:

- Generate a calibration certificate for your rtd pt100. This document should include:

- Sensor identification (serial number, model).

- Date of calibration.

- Reference standards used (with traceability information).

- Calibration points and corresponding measured values from the rtds pt100 and the reference.

- Calculated errors and any adjustments made.

- Uncertainty of measurement.

- Next calibration due date.

-

- Generate a calibration certificate for your rtd pt100. This document should include:

- Preparation:

Common Challenges and Best Practices for RTD PT100 Calibration

Even with the right equipment, calibration of an rtd pt100 can present challenges. We've identified some common pitfalls and offer best practices:

- Immersion Depth: Insufficient immersion leads to heat transfer errors from the stem. Always ensure deep immersion of the rtds pt100 sensing elements.

- Thermal Mass and Stabilization Time: Larger probes or those in less thermally conductive mediums take longer to stabilize. Patience is key when calibrating rtds pt100.

- Lead Wire Effects: This is particularly problematic for 2-wire rtds pt100 sensors. For high accuracy, always opt for 3-wire or 4-wire RTDs, or use lead wire compensation techniques.

- Environmental Influences: Drafts, fluctuating ambient temperatures, or even hand warmth can affect readings, especially for sensitive an rtd pt100. Perform calibration in a stable environment.

- Traceability: Always ensure your reference standards are calibrated and traceable to national or international metrology institutes. This underpins the validity of your rtds pt100 calibration.

Maintaining Your Calibrated RTD PT100

Proper care extends the life and accuracy of your calibrated rtd pt100. Always handle them carefully, avoiding mechanical shock. Store them in protective cases when not in use and keep them away from extreme temperatures or corrosive environments. Regular visual inspections of the rtds pt100 can also help identify potential issues before they impact performance.

Conclusion: The DXM Advantage in Precision Temperature Sensing

Mastering how to calibrate rtd pt100 sensors is fundamental to achieving and maintaining precision in temperature-critical applications. Accurate temperature measurement is not merely a technicality; it is a cornerstone of quality, efficiency, and safety across every industry we serve. By diligently following these guidelines, you ensure that your rtd pt100 sensors deliver the reliable data you depend on.

At DXM, we pride ourselves on being one of China's foremost and largest ISO 9001:2008-certified modernization electronics manufacturers, with over 29 years of industry expertise. Our powerful research and development capabilities allow us to produce high-quality, sensitive electronic components, including a comprehensive range of temperature sensors like the rtds pt100, PT1000 temperature sensors, and various NTC/PTC thermistors. We understand the critical role these components play in automotive electronics, consumer electronics, home appliances, and industrial systems.

Investing in the correct calibration practices for your rtds pt100 ensures the longevity and accuracy of your measurements, directly impacting your operational success. For reliable, high-performance temperature sensing solutions, including superior quality rtd pt100 sensors, trust DXM. We are committed to providing the foundational components that empower your precision systems. Explore our extensive range of thermistors, varistors, capacitors, and advanced sensor technologies to elevate your applications. Partner with us for unparalleled expertise and quality in sensitive electronic components.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

13th July 2025

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

Capacitor 104 Value: Essential Guide for Electronics Professionals

Positive Temperature Coefficient Heater: An Essential Guide of PTC Heater

Price and Payment

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

Customized Services

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

You may also like

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd