What is an Electronic Ballast PTC Thermistor? Insights from DXM.

Find the role of a ballast electronic PTC thermistor with DXM insights. Learn how this key component enhances electronic ballast safety and performance in lighting systems. Explore DXM’s expert overview for efficient, reliable ballast electronic solutions.

- What is an Electronic Ballast PTC Thermistor?

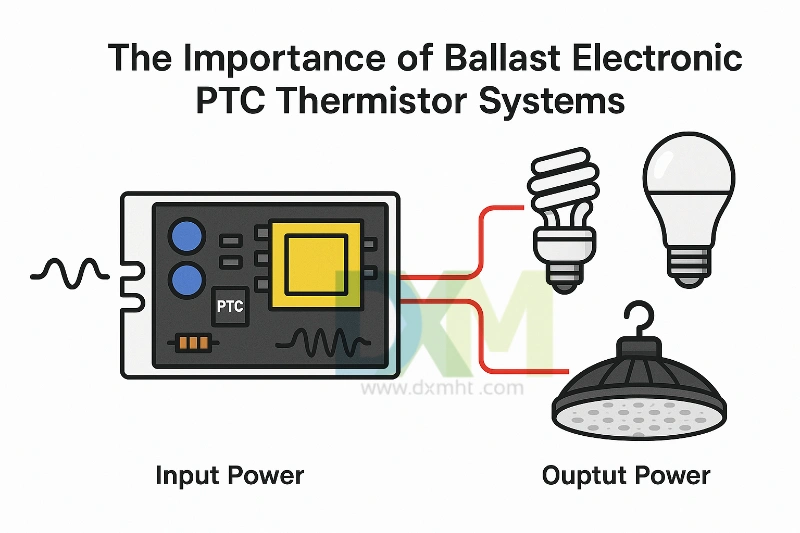

- The Importance of Ballast Electronic PTC Thermistor Systems in Modern Power Solutions

- The Essential Role of PTC Thermistor in Ballast Electronic Systems

- The Crucial Role of PTC Thermistor in Ballast Electronic Systems

- Preheating Lamp Filaments for a Smooth Start-Up

- Startup Current Limiting and Surge Protection

- Overcurrent and Overtemperature Protection

- Stabilization and Control for Consistent Performance

- Unlocking Performance and Safety: Benefits of PTC Thermistors in Ballasts

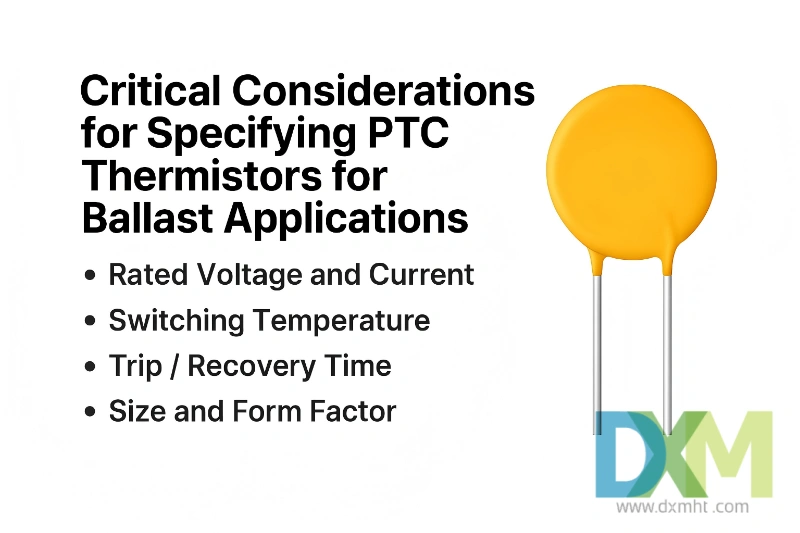

- Critical Considerations for Specifying PTC Thermistors for Ballast Applications

- Beyond Illumination: Broader Applications and Future Horizons

- Partnering for Excellence: Why DXM is Your Trusted Thermistor Expert

- Ensuring Superior Performance with PTC Thermistor in Ballast Electronic Systems

Ballast electronic systems rely heavily on PTC thermistor for enhanced performance and safety. These thermistors act as a critical component in regulating temperature within the system. What is electronic ballast? It’s a device that controls the current flow to lamps, ensuring efficient lighting operations.

By integrating PTC thermistors, electronic ballasts can prevent overheating, enhancing longevity and safety. This article explores how PTC thermistor improves performance, reliability, and energy efficiency in modern lighting and power systems. It's ability to self-regulate temperature makes it indispensable in the design of electronic ballasts.

What is an Electronic Ballast PTC Thermistor?

In modern electronics, particularly in lighting and power systems, the synergy between ballast electronic systems and PTC thermistor is vital. For professionals in the thermistor industry, understanding this relationship is crucial. It goes beyond just component knowledge; it’s about achieving safety, efficiency, and longevity.

At DXM, with over 29 years of expertise, we see firsthand how well-designed ballast electronic systems integrate PTC thermistor to enhance system performance.

What is electronic ballast? It’s a device that controls current flow to lamps, ensuring efficient operation. The integration of PTC thermistor ensures these systems stay safe and reliable.

The Importance of Ballast Electronic PTC Thermistor Systems in Modern Power Solutions

A ballast electronic is more than just a current limiter; it’s an advanced device that regulates current for various loads, such as fluorescent lamps, HID lamps, and LED drivers. Unlike older magnetic ballasts, ballast electronic systems operate at high frequencies, typically from 20 kHz to 60 kHz. This frequency range offers several key advantages:

-

Enhanced Energy Efficiency: By minimizing power losses, ballast electronic systems convert more input power into light output, saving energy.

-

Improved Light Quality: High-frequency operation eliminates flicker, providing a stable and comfortable illumination.

-

Extended Lamp Life: With precise control over ignition and operation, electronic ballasts reduce filament stress, extending lamp life.

-

Compact Design: These ballasts are smaller and lighter, fitting easily into a wider variety of fixtures.

From automotive electronics to industrial lighting, ballast electronic systems are critical in modern power solutions. It's integration with PTC thermistor further enhances safety and efficiency, ensuring long-lasting performance in diverse applications.

The Essential Role of PTC Thermistor in Ballast Electronic Systems

A PTC thermistor, or Positive Temperature Coefficient thermistor, is a resistor whose resistance increases as its temperature rises. This characteristic, driven by ceramic semiconductor materials like barium titanate, is crucial for various ballast electronic applications. Unlike NTC thermistors, which decrease in resistance with temperature, PTC thermistors offer self-regulating properties. Here's what makes them so valuable:

-

Switching Behavior: Once a specific Curie temperature is reached, the resistance rises sharply, acting like a switch. This provides precise control in ballast electronic systems.

-

Self-Heating: As current flows through a PTC thermistor, it heats up. As its temperature rises, resistance increases, limiting current and reducing heat, offering self-regulation.

-

Overcurrent Protection: The sharp resistance rise helps protect circuits from current surges, acting as a resettable fuse.

-

Temperature Sensing and Control: PTC thermistors can detect temperature thresholds and trigger circuit responses, essential for ballast electronic systems.

With our experience at DXM, we've seen firsthand how PTC thermistor enhances performance and safety in electronic systems, from ballast electronic to circuit protection.

The Crucial Role of PTC Thermistor in Ballast Electronic Systems

The integration of PTC thermistors within a ballast electronic system is essential for optimal performance and safety. These components help manage temperature and protect circuits, ensuring reliable operation.

Preheating Lamp Filaments for a Smooth Start-Up

Fluorescent lamps need to heat their filaments before ignition to avoid a cold strike, which can shorten lifespan. PTC thermistors facilitate this process by allowing current to flow initially, heating the filaments. As the thermistor heats up, its resistance increases, cutting off the preheating current. This controlled sequence is crucial for maximizing lamp life.

Startup Current Limiting and Surge Protection

At start-up, ballast electronic systems can draw high inrush currents, which may damage components. A PTC thermistor in the power input acts as a current limiter. Initially, it has low resistance, but as current flows, its resistance rises, limiting the surge. After the surge subsides, the thermistor cools and returns to normal, ensuring smooth operation.

Overcurrent and Overtemperature Protection

If the ballast experiences a fault, such as a short circuit, the PTC thermistor can protect the system. When excessive current flows, the thermistor’s resistance increases, reducing the fault current to safe levels. If the ballast overheats, the thermistor senses the temperature and can trigger a shutdown, preventing damage. This self-resetting feature ensures continuous operation without manual intervention.

Stabilization and Control for Consistent Performance

PTC thermistors help stabilize ballast electronic systems. Their resistance changes with temperature, maintaining optimal operating conditions in varying environments. This ensures consistent light output and performance, prolonging the lifespan of both the lamp and ballast.

At DXM, we specialize in designing PTC thermistors that meet the precise requirements of these critical functions. This guarantees the reliable and safe operation of ballast electronic systems.

Unlocking Performance and Safety: Benefits of PTC Thermistors in Ballasts

The judicious incorporation of PTC thermistors into ballast electronic designs brings forth a multitude of advantages that resonate deeply with our commitment to quality and innovation:

* Enhanced Reliability and Longevity: By meticulously controlling startup sequences and providing robust overcurrent protection, PTC thermistors significantly reduce stress on other ballast components and the lamps themselves. This translates directly into a longer operational life for the entire system, minimizing replacement cycles and associated costs.

Superior Safety Features: The self-resetting nature of a PTC thermistor makes it an ideal safety component. It acts as an automatic circuit breaker, protecting against potentially hazardous overcurrents and overtemperatures without requiring manual resetting or replacement, thus enhancing user safety and reducing maintenance burdens.

* Improved Energy Efficiency: While not directly enhancing efficiency in terms of light output, the protective functions of PTC thermistors ensure that the ballast operates within its optimal parameters, preventing energy waste due to component degradation or fault conditions.

* Reduced Maintenance and Downtime: Systems equipped with PTC thermistors are more resilient to transient faults.

Their self-resetting capability means less need for service calls or manual intervention after minor power disturbances or momentary overloads, leading to greater uptime.

* Compact and Cost-Effective Solutions: Replacing traditional fuses and more complex protection circuits with a single, highly effective PTC thermistor can lead to more compact ballast designs and reduced manufacturing costs, without compromising on performance or safety.

We pride ourselves on supplying quality PTC thermistors that deliver these tangible benefits to our partners across various industries.

Critical Considerations for Specifying PTC Thermistors for Ballast Applications

Selecting the right PTC thermistor for a specific ballast electronic application requires careful consideration of several key parameters to ensure optimal performance and reliability:

* Rated Voltage and Current: The PTC thermistor must be able to withstand the maximum operating voltage and current of the ballast circuit without damage.

* Switching Temperature (Curie Temperature): This is the temperature at which the PTC thermistor's resistance begins to rise sharply. It must be carefully chosen to align with the required preheating temperature of the lamp and the desired protection threshold.

* Resistance at Room Temperature (R25): This initial resistance determines the initial current flow for preheating or normal operation.

* Time to Trip/Recovery Time: For protection applications, how quickly the PTC thermistor reacts to an overcurrent (trip time) and how quickly it cools down and resets (recovery time) are crucial.

* Power Dissipation: Understanding the maximum power the PTC thermistor can safely dissipate is vital for thermal management.

* Size and Form Factor: Physical dimensions must fit within the constrained space of the ballast assembly.

* Environmental Operating Conditions: The PTC thermistor must perform reliably across the expected temperature range and humidity levels of the application environment.

* Reliability and Standards Compliance: Partnering with an ISO 9001:2008-certified manufacturer like DXM ensures that the PTC thermistors meet rigorous quality control and industry standards, which is paramount for long-term system stability.

Our team, backed by decades of experience, assists our clients in meticulously selecting the ideal PTC thermistors for their unique ballast electronic designs, ensuring performance, safety, and compliance.

Beyond Illumination: Broader Applications and Future Horizons

While we've focused on the critical relationship between ballast electronic and PTC thermistor in lighting, it's important to recognize that the applications for PTC thermistors extend far beyond. Our products are widely utilized in dozens of major categories, including:

* Automotive Electronics: For battery management systems, cabin heating, and sensing.Consumer Electronics: In power supplies, motor protection, and display backlights.

* Home Appliances: For PTC heaters, fan heaters, and temperature control in various devices.

* Power Electronics: In power supply units for inrush current limiting and overcurrent protection.

Industrial Electronics: For motor protection, circuit overcurrent protection, and sensing in automation systems.

* Telecommunication: In line protection modules and network equipment. Looking ahead, the role of the PTC thermistor will only grow as industries demand more intelligent, efficient, and robust electronic systems.

We anticipate continued innovation in miniaturization, higher temperature capabilities, and integration into smart, connected devices, where precise thermal management and protection are paramount. Our powerful research and development capabilities are continuously exploring these frontiers, ensuring our products remain at the cutting edge.

Partnering for Excellence: Why DXM is Your Trusted Thermistor Expert

As one of the foremost, largest, and ISO 9001:2008-certified modernization electronics manufacturers in China, DXM has been at the forefront of sensitive electronic component manufacturing since 1996. Our more than 29 years of industry expertise are not just a number; they represent a deep reservoir of knowledge, innovation, and commitment to quality that benefits every one of our partners.

We specialize in supplying high-quality thermistors, including PTC thermistors and NTC thermistors, alongside a comprehensive range of components like varistors, high voltage capacitors, ceramic disc capacitors (Y capacitors), and various temperature sensors (PTC, NTC, RTD including PT100 and PT1000). This broad product portfolio, combined with our powerful R&D capabilities, positions us uniquely to address the diverse and evolving needs of industries relying on advanced electronic components.

When you choose DXM, you're not just acquiring components; you're gaining a partner dedicated to optimizing your designs, enhancing your product reliability, and ensuring you have access to the most advanced and dependable PTC thermistor solutions for your ballast electronic applications and beyond.

Ensuring Superior Performance with PTC Thermistor in Ballast Electronic Systems

The ballast electronic system is the core of modern lighting and power systems. Its efficient operation heavily relies on the precise functionality of the PTC thermistor. As discussed, PTC thermistors perform essential roles, including gentle lamp ignition, inrush current limiting, and comprehensive overcurrent and overtemperature protection. These features ensure both longevity and safety for the system.

For professionals in the thermistor industry, understanding the relationship between ballast electronic systems and PTC thermistors is crucial. It helps in designing safer and more efficient products.

At DXM, we offer an extensive range of high-quality PTC thermistors. With decades of expertise, our team is equipped to help you integrate the perfect thermistor into your ballast electronic design. We ensure your systems meet and exceed performance and safety standards.

Partner with us to unlock the full potential of your electronic ballast designs. Experience the benefits of superior components and expert technical support.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Shipment

1)Small order quantity and small packing:cargo may be arranged by courier;

2)Bulk order and big volume:shipment may be arranged by sea or by air as per customer’s requirements on FOB, C&F,CIF or LCL terms and do prompt shipment which is very important for our customers, so we do this matter seriously and we may arrange our shipment in time due to our rich experiences in this line. We may also accept the shipment on the term of freight prepaid or freight collect.

Price and Payment

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

You may also like

PTC Resistors MZ71 Degauss Thermistor for TV monitor Degaussing

PTC Thermistor TV Degausser-Reliable MZ73 | DXM

PTC Elements for Telecom Termination MZ24 Series | DXM

PTC Termistor MZ31 Series: Reliable Overload Protection for Circuit Applications

PTC Thermal Resistor 19P for Overcurrent and Overload Protection

Linear PTC Thermistor Precision Temperature Sensing (KTY Series)

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd