AC Capacitors: Understanding Types, Applications, and Selection Criteria

This blog post provides a comprehensive guide to AC capacitors for professionals, covering types, applications, selection, and troubleshooting. Learn about film, electrolytic, ceramic, and motor run capacitors and how to choose the right one for your needs.

- AC capacitors are vital components in electrical systems, ensuring stable operation and efficient performance. Often referred to as capacitors, these devices store and release electrical energy. AC capacitors come in various types, each designed for specific applications. The most common types include aluminum electrolytic, ceramic, and film capacitor. Choosing the right capacitor is essential for optimal function, considering factors like voltage rating, capacitance, and application needs. Proper selection enhances system reliability, energy efficiency, and durability. Understanding the role and specifications of AC capacitors can significantly improve electrical system performance.

Understanding AC Capacitors Functionality

AC capacitors store electrical energy in an electric field, unlike inductors which store energy in a magnetic field. In AC circuits, this energy storage and release happens cyclically, allowing capacitor to perform several critical functions. its impedance, inversely proportional to frequency, means it exhibits high impedance to low-frequency AC signals and low impedance to high-frequency AC signals. This characteristic is central to many of its applications. The key parameter specifying an AC capacitor's performance is its capacitance, measured in Farads (F), along with its voltage rating and tolerance. Selecting the correct AC capacitor for a given application hinges on understanding these specifications and the circuit's requirements.

Types of AC Capacitors

The market offers a wide range of AC capacitors, each designed for specific applications. We'll delve into the most common types:

* Film Capacitors: These are known for their high stability, low dielectric absorption, and wide operating temperature ranges. Common dielectric materials include polypropylene, polyester, and metallized film. Film capacitors are widely used in high-frequency applications, including power supplies, filters, and coupling circuits. Their precise capacitance and low tolerance make them ideal for critical applications.

* Electrolytic Capacitors: Electrolytic AC capacitor is often used in applications requiring large capacitance values in a relatively small package size. It utilizes an aluminum or tantalum oxide layer as the dielectric, offering significantly higher capacitance than film capacitors of comparable size. However, it typically exhibits higher tolerances and is generally more sensitive to temperature variations than film capacitor. Furthermore, polarity must be observed in electrolytic capacitor use. AC electrolytic capacitors are often used in motor run capacitors.

* Ceramic Capacitor: Ceramic AC capacitor is widely used due to its small size, high capacitance, and low cost. It's often found in filter circuits and coupling applications. Different ceramic materials offer varying dielectric constants, impacting capacitance. It may be polarized or non-polarized, depending on the application. Its performance can be affected by temperature, and it usually exhibits a higher tolerance level than film capacitor.

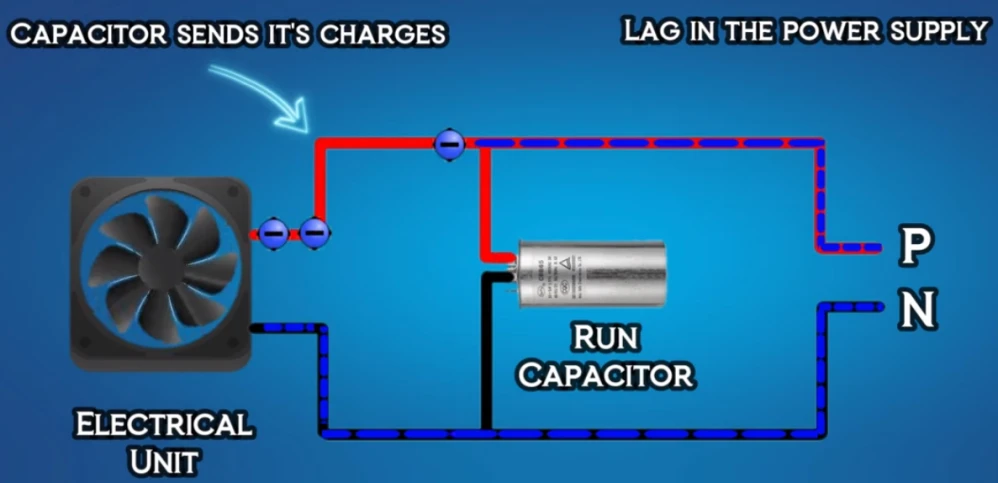

* Motor Run Capacitors: Specifically designed for use in AC induction motors, these capacitors are typically electrolytic and exhibit a high capacitance and voltage rating. Their function is to improve motor starting torque and running efficiency. Their selection hinges on the motor's specifications. Choosing the correct capacitor ensures optimal performance and prevents motor damage.

Applications of AC Capacitors

The versatility of AC capacitors makes them indispensable in various applications across diverse industries. Let's explore some of their prominent uses:

* Power Factor Correction: Improving power factor in AC circuits using capacitor reduces energy losses and improves overall efficiency. This is particularly relevant in industrial settings where large AC motors operate.

* Filtering: AC capacitors are essential components in filter circuits, removing unwanted frequencies and noise from signals. They are used in audio systems, power supplies, and signal processing applications.

* Coupling and Decoupling: In signal processing and electronics, AC capacitor facilitates signal transfer between different circuit stages while blocking DC components. Decoupling capacitor stabilizes voltage in integrated circuits.

* Timing Circuits: The charging and discharging characteristics of AC capacitor is utilized in timing circuits in various applications, including oscillators and timing controls.

Motor Starting and Running: As mentioned, AC capacitors are critical components in AC motor applications, ensuring efficient starting and continuous operation.

Selecting the Right AC Capacitors

Choosing the appropriate AC capacitor involves considering several key factors:

* Capacitance Value: This dictates the capacitor's energy storage capacity and its impedance at a given frequency.

* Voltage Rating: The capacitor's maximum operating voltage must exceed the expected voltage in the circuit.

* Tolerance: The permissible deviation of the actual capacitance from the nominal value. Tight tolerances are crucial in precision applications.

* Temperature Coefficient: The change in capacitance with temperature variation.

* Dielectric Material: The choice of dielectric material (e.g., polypropylene, ceramic) impacts the capacitor's performance characteristics, cost, and suitability for specific applications.

* ESR (Equivalent Series Resistance): A crucial parameter, especially at higher frequencies, affecting power dissipation and efficiency.

* ESL (Equivalent Series Inductance): This parasitic inductance becomes significant at higher frequencies and can impact the capacitor's performance.

Troubleshooting AC Capacitors Issues

Identifying faulty AC capacitors can be challenging but crucial for maintaining system integrity. We often see issues stemming from incorrect selection, aging, and excessive heat. Visual inspection may reveal bulging or leakage. Testing using a capacitance meter and ESR meter is recommended to verify capacitance and ESR values. Replacement should always be with a component with appropriate specifications.

Frequently Asked Questions (FAQs)

Q: What is the difference between AC and DC capacitors?

A: While both store energy, AC capacitors are designed to handle alternating current and are usually non-polarized, unlike many DC electrolytic capacitors.

Q: How do I determine the appropriate capacitance value for my application?

A: The required capacitance depends on the specific application. Circuit design calculations and simulations usually determine this.

Q: Can I use a DC capacitor in an AC circuit?

A: Generally, no. Using a polarized DC capacitor in an AC circuit can lead to damage and failure.

Q: What are the safety precautions when handling AC capacitors?

A: Always discharge capacitors before handling to prevent electric shock. Observe voltage ratings to prevent damage.

Conclusion

AC capacitors are essential passive components in various electrical and electronic systems. Understanding their types, functionality, and selection criteria is crucial for professionals involved in circuit design, maintenance, and troubleshooting. By carefully considering the factors discussed, you can ensure that you select the correct AC capacitor for your application, maximizing efficiency and reliability. Proper selection of AC capacitors is essential for optimal system performance and longevity. Selecting the wrong capacitor can lead to component failure, system malfunctions, and safety hazards.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Logistics

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

Price and Payment

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

You may also like

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd