Converting uF to F: The Complete Guide to Capacitance Conversion

Discover the essentials of capacitance conversion with DXM’s comprehensive guide on converting uF to F. Whether you're an electronics enthusiast or a professional, learn how to seamlessly convert from uF to F and nf to uF. Our detailed instructions ensure precise and efficient conversions, enhancing your understanding of capacitance values. Explore the intricacies of capacitance conversion and optimize your electronic projects with DXM’s expert insights. Unlock the potential of your devices with accurate and reliable conversion techniques.

- Understanding Capacitance Unit and Conversion

- Understanding Capacitance Units

- Basic Definitions:

- The Basics: What Are Farads?

- Conversion Factor

- Conversion Formulas

- Converting to Smaller Units:

- Converting to Larger Units:

- Conversion Process

- Converting µF to F

- Converting F to µF

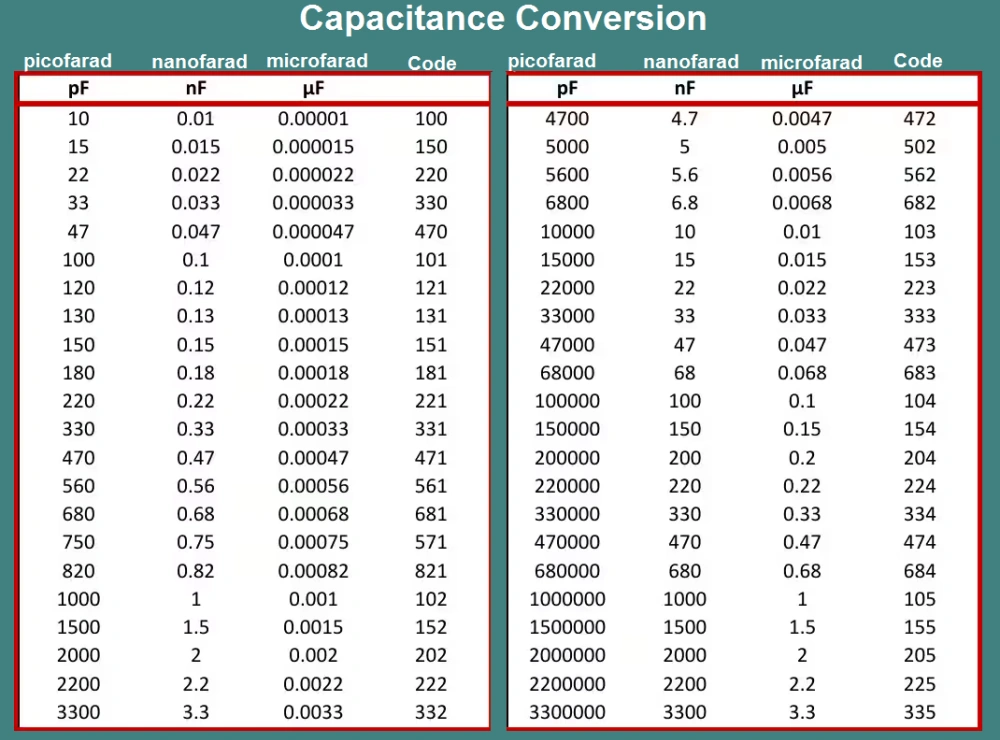

- Conversion Chart

- Quick Reference:

- Quick Reference Table

- Fundamental Principles of Capacitance Conversion

- Practical Applications of Capacitance Conversion

- FAQ: Frequently Asked Questions

- Conclusion: Master Capacitance Conversion

In the electrical engineering world, understanding capacitance conversion is pivotal. Knowing how to convert values between units such as uF to F and nF to uF is essential for professionals and enthusiasts alike. This guide dives into capacitance conversion, exploring concepts, practical applications, and expert tips for efficiency.

Understanding Capacitance Unit and Conversion

Capacitance is measured in Farads (F), but often expressed in microfarads (uF) or nanofarads (nF). Why? Because electronic components usually work with smaller values. Comprehending these units and conversions is crucial in design and troubleshooting. Electronic engineers frequently need to convert uF to F when working with various circuit components. Capacitance conversion skills are fundamental for accurate component selection and circuit design. The relationship between nF to uF also plays a crucial role in modern electronics.

Understanding Capacitance Units

Basic Definitions:

- Farad (F): The SI unit of capacitance, defined as the capacitance of a capacitor that can store one coulomb of charge at one volt.

- Microfarad (µF): A subunit of farads, where

1 µF = 10-6 F. - nF (Nanofarad) = 10-9 F

- pF (Picofarad) = 10-12 F

-

The Basics: What Are Farads?

- The Farad is the SI unit of capacitance. However, in practical electronics, farads are too large. Instead, microfarads (µF) and nanofarads (nF) are common. Understanding how to convert uf to f is important when dealing with practical capacitors. Microfarads (uF) A microfarad is one-millionth of a Farad. It's often used for capacitors in power supply circuits. Conversion of uf to f plays a key role in ensuring proper circuit functionality. Nanofarads (nF) Nanofarads, one-billionth of a Farad, are commonly found in advanced circuit designs. Engineers often need to convert between nf to uf or uf to f during capacitance conversion tasks.

-

Conversion Factor

- To convert from microfarads to farads, use the conversion factor:

1 µF = 1 × 10-6 F -

Conversion Formulas

-

Converting to Smaller Units:

-

Farad to Microfarad (uf to f): multiply by 1,000,000 (x 106)

-

Microfarad to Nanofarad: multiply by 1,000 (x 103)

-

Nanofarad to Picofarad: multiply by 1,000 (x 103)

-

Converting to Larger Units:

-

Picofarad to Nanofarad: divide by 1,000 (÷ 103)

-

Nanofarad to Microfarad (nf to uf): divide by 1,000 (÷ 103)

-

Microfarad to Farad : divide by 1,000,000 (÷ 106)

Conversion Process

Converting µF to F

Formula:Capacitance in F = Capacitance in µF × 10-610 µF = 10 × 10-6 F = 0.00001 F

Converting F to µF

Reverse Conversion: To convert from farads back to microfarads, multiply by1,000,000.Capacitance in µF = Capacitance in F × 1,000,0000.01 F = 0.01 × 1,000,000 µF = 10,000 µF

Conversion Chart

| From | To | Formula |

|---|---|---|

| Farad (F) | Microfarad (µF) | F × 1,000,000 |

| Microfarad (µF) | Nanofarad (nF) | µF × 1,000 |

| Nanofarad (nF) | Picofarad (pF) | nF × 1,000 |

| Picofarad (pF) | Nanofarad (nF) | pF ÷ 1,000 |

| Nanofarad (nF) | Microfarad (µF) | nF ÷ 1,000 |

| Microfarad (µF) | Farad (F) | µF ÷ 1,000,000 (uf to f ) |

Quick Reference:

1 F = 1,000,000 µF = 1,000,000,000 nF = 1,000,000,000,000 pF The conversion is one of the most fundamental aspects of capacitance conversion. Similarly, knowing how to go from nf to uf is essential in practical electronic applications. Proper Capacitance Conversion ensures the accuracy and reliability of electronic circuits by allowing engineers to interpret and adjust capacitor values effectively.Quick Reference Table

| Capacitance (µF) | Capacitance (F) |

|---|---|

| 1 µF | 1.0 × 10-6 F |

| 10 µF | 1.0 × 10-5 F |

| 100 µF | 1.0 × 10-4 F |

| 1000 µF | 1.0 × 10-3 F |

| 1,000,000 µF | 1.0 F |

Tools for Conversion

- Online Calculators: Explore DXM Capacitance Conversion Calculator for quick conversions between various capacitance units.

- Conversion Charts: Keeping a chart handy can help when working on electronic projects where multiple unit conversions are needed.

By understanding these principles and using the formulas provided, converting between uf to f or nf to uf becomes a straightforward process essential for working with capacitors in electronic circuits.

Fundamental Principles of Capacitance Conversion

When performing capacitance conversion, understanding these relationships is crucial. Engineers must master nF to uF conversions for precise component selection. Key Conversion Calculations:Efficient circuit design and optimization require precise calculations. Here we discuss the conversion between these units. Converting uF to F:Converting microfarads to farads involves dividing by one million. For instance, 1 uF equals 0.000001 F. From nF to uF:To convert nanofarads to microfarads, divide by 1000. So, 1 nF converts to 0.001 uF. Real-World Applications: Understanding these conversions isn't just for academia. They play vital roles in various fields and applications. Circuit Design and Analysis: In circuit design, engineers use capacitance values to filter noise or stabilize voltage. Incorrect conversions can result in system failures. Component Replacement and Compatibility: Correct capacitor replacements depend on conversion accuracy. Using incorrect capacitance can damage components.

Practical Applications of Capacitance Conversion

Power Supply Design: Converting uF to F is crucial when designing power supply filters. A typical application might require converting 4700 uF to F for proper component specification. Signal Processing Circuits: Many signal processing applications require nF to uF conversion for coupling capacitor selection.

FAQ: Frequently Asked Questions

1.How do I convert uF to F in practice?

To convert uF to F, divide the microfarad value by 1,000,000. For example, 2200 uF equals 0.0022 F.

2.What's the easiest way to perform nF to uF conversion?

For nF to uF conversion, divide the nanofarad value by 1,000. Example: 4700 nF equals 4.7 uF.

3.Mastering Capacitance Conversion

Understanding how to convert uF to F and perform accurate capacitance conversion is essential for electronic design success. These skills form the foundation of proper component selection and circuit optimization.

4. Why is knowing capacitance conversion important?

Accurate conversions ensure efficient and safe electrical circuit function.

5. How do I convert nF to uF?

Divide the nF value by 1000 to get uF.

6. Are there tools for capacitance conversion?

Yes, online converters and calculator apps provide quick solutions.

Conclusion: Master Capacitance Conversion

Whether designing circuits or replacing components, mastering capacitance conversion is vital. Understanding conversions between uF to F and nF to uF ensures your design's success and efficiency.

Author: Ivan Huang

© 2024 DXM Blog. All rights reserved.

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Shipment

1)Small order quantity and small packing:cargo may be arranged by courier;

2)Bulk order and big volume:shipment may be arranged by sea or by air as per customer’s requirements on FOB, C&F,CIF or LCL terms and do prompt shipment which is very important for our customers, so we do this matter seriously and we may arrange our shipment in time due to our rich experiences in this line. We may also accept the shipment on the term of freight prepaid or freight collect.

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

Price and Payment

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

You may also like

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd