Ceramic Resistors: Choosing the Right Manufacturers

Learn how to choose the right ceramic resistors and reliable ceramic resistor manufacturers. This guide covers key factors, application considerations, and FAQs for professionals. Discover why quality matters.

- Ceramic Resistors: Your Guide to Choosing the Right Resistor Manufacturers

- Understanding Ceramic Resistors

- Key Factors to Consider When Selecting Ceramic Resistors

- Applications of Ceramic Resistors

- Selecting Reliable Ceramic Resistor Manufacturers

- Frequently Asked Questions (FAQs)

- Q: What are the different types of ceramic resistors?

- Q: How do I determine the appropriate power rating for my ceramic resistor?

- Q: What are the advantages of using ceramic resistors compared to other types of resistors?

- Q: Where can we find reliable ceramic resistor manufacturers?

- Conclusion

Ceramic Resistors: Your Guide to Choosing the Right Resistor Manufacturers

Choosing the right ceramic resistor manufacturers is crucial for any project involving ceramic resistors. The performance and reliability of your electronics depend heavily on the quality of these components. We, as experts in the thermistor industry, understand this critical need and have compiled this guide to help you navigate the selection process effectively.

Understanding Ceramic Resistors

Ceramic resistors are passive electronic components that resist the flow of electrical current. Their construction utilizes a ceramic material as the resistive element, offering advantages in terms of stability and temperature resistance compared to other resistor types. Different ceramic resistor manufacturers offer variations in composition, size, and power rating, catering to a wide range of applications. The selection of the appropriate ceramic resistor hinges upon understanding your specific application requirements.

Key Factors to Consider When Selecting Ceramic Resistors

Several critical factors influence the selection of suitable ceramic resistors for your project. These include:

* Power Rating: The maximum power a resistor can dissipate without overheating. This is a fundamental specification, directly impacting the resistor’s size and heat management needs. Higher power applications demand higher power rated ceramic resistors.

* Resistance Value and Tolerance: The precise resistance value and the acceptable deviation from that value are crucial. Tolerance dictates the accuracy required for your circuit. Different ceramic resistor manufacturers offer varying tolerance levels.

* Temperature Coefficient: This indicates how much the resistance changes with temperature fluctuations. Low temperature coefficients are vital for applications demanding stable performance across varying temperature ranges.

* Size and Physical Dimensions: The physical size of the ceramic resistor must be compatible with your circuit's layout and available space. Several ceramic resistor manufacturers offer various form factors, including surface mount devices (SMDs) and through-hole components.

* Operating Temperature Range: This is the temperature range within which the ceramic resistor can operate reliably. Exceeding this range may lead to component failure.

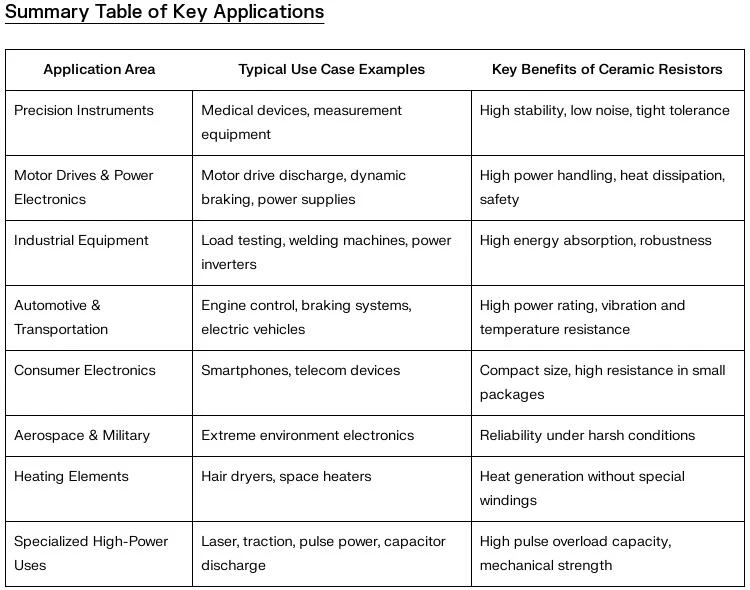

Applications of Ceramic Resistors

Ceramic resistors find applications across a broad spectrum of industries, including:

* Automotive Electronics: Used in various automotive systems requiring stability and reliability.

* Consumer Electronics: Commonly used in diverse consumer electronic devices.

* Home Appliances: Integral components in various home appliance circuits.

* Power Electronics: Crucial for power management and control in various applications.

* Industrial Electronics: Used extensively in industrial control systems and instrumentation.

* Telecommunication: Essential in telecommunication infrastructure and equipment.

Selecting Reliable Ceramic Resistor Manufacturers

Choosing a reputable ceramic resistor manufacturer is paramount. We recommend you look for manufacturers who:

* Adhere to strict quality control measures: ISO 9001 certification is a good indication of commitment to quality.

* Provide comprehensive technical documentation and support: Clear specifications, datasheets, and readily available support are essential for successful integration.

* Offer a wide range of products: A diverse product portfolio ensures you find the perfect match for your specific needs.

* Have a proven track record and positive customer reviews: Industry reputation and positive feedback signal reliability and customer satisfaction.

* Are capable of meeting your volume and delivery requirements: Consider their manufacturing capacity and ability to meet your project’s timeline.

DXM, for instance, is a leading ceramic resistor manufacturer in China, boasting over 28 years of experience and ISO 9001:2008 certification. We offer a broad range of high-quality ceramic resistors, catering to various applications. We pride ourselves on providing exceptional support and consistently meeting our customers' needs.

Frequently Asked Questions (FAQs)

Q: What are the different types of ceramic resistors?

A: There are several types, each with unique characteristics, including high-precision, high-voltage, and high-power ceramic resistors. The best choice depends on the specific application requirements.

Q: How do I determine the appropriate power rating for my ceramic resistor?

A: The power rating should be significantly higher than the expected power dissipation to prevent overheating and failure. Consult datasheets and application notes for accurate calculation.

Q: What are the advantages of using ceramic resistors compared to other types of resistors?

A: Ceramic resistors offer superior stability, higher power handling capabilities, and better temperature resistance compared to alternatives like carbon film or metal film resistors.

Q: Where can we find reliable ceramic resistor manufacturers?

A: Thorough research is vital. Look for manufacturers with certifications, positive reviews, and robust technical support. DXM is one such example.

Conclusion

Selecting appropriate ceramic resistors and identifying reliable ceramic resistor manufacturers is key to successful electronics design and manufacturing. By considering the factors outlined above and choosing a reputable supplier, you can ensure the performance, reliability, and longevity of your products. Contact DXM today to learn more about our comprehensive range of high-quality ceramic resistors and how we can support your project.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

Logistics

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

Price and Payment

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

You may also like

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd