Understanding Sensing Temperature: A Comprehensive Guide to Temperature Sensors

Explore "Understanding Sensing Temperature: A Comprehensive Guide to Temperature Sensors" by DXM. As leading sensor manufacturers, we delve into the intricacies of sensing temperature and provide insights into various temperature sensors. Discover cutting-edge solutions tailored for diverse applications, ensuring precision and reliability. Trust DXM for unmatched expertise in the world of temperature sensor.

- How Sensing Temperature Work

- Voltage Measurement

- Resistance Change

- Types of Temperature Sensors

- Contact Temperature Sensors

- Non-Contact Temperature Sensors

- Applications of Temperature Sensors

- Household Appliances

- Automotive Systems

- Medical Devices

- Industrial Systems

- HVAC Systems

- Consumer Electronics

- Advanced Technologies in Temperature Sensing

- Wireless Temperature Sensor

- Smart Temperature Sensor

- Flexible Temperature Sensor

- Challenges in Sensing Temperature

- Environmental Factors

- Calibration

- Conclusion

- FAQs Section

- What are temperature sensors used for?

- What is the principle behind temperature sensors?

- What types of temperature sensors exist?

- How do thermistors work?

- How do sensor manufacturers ensure accuracy?

Sensing temperature is essential for many applications. From household appliances to industrial systems, accurate temperature data is crucial. Sensor manufacturers are constantly developing better Temperature Sensors for improved efficiency and safety. These innovations ensure reliable sensing temperature solutions, vital for controlling various processes effectively. Choosing the right Temperature Sensor enhances system performance and safety. Leading sensor manufacturers such as DXM focus on providing precision and stability to meet industry demands. Accurate sensing temperature drives operational success and safety across diverse sectors.

How Sensing Temperature Work

Sensing temperature operates on the principle that electrical properties change with temperature variations. These changes are measurable and converted into electrical signals.The most common sensing temperature mechanisms include thermocouples, thermistors, and RTDs. They measure variations in resistance, voltage, or current.The most common temperature sensing mechanisms include:

Voltage Measurement

Some temperature sensors measure the voltage changes across specific materials, such as diodes, which vary with temperature. As temperature rises, the voltage typically increases, allowing for reliable temperature readings.

Resistance Change

Another common mechanism involves the change in electrical resistance. For example, thermistors and Resistance Temperature Detectors (RTDs) use this principle. NTC thermistors have a negative temperature coefficient, meaning their resistance decreases as the temperature increases. This allows for precise temperature measurement, which is essential in numerous fields.

Types of Temperature Sensors

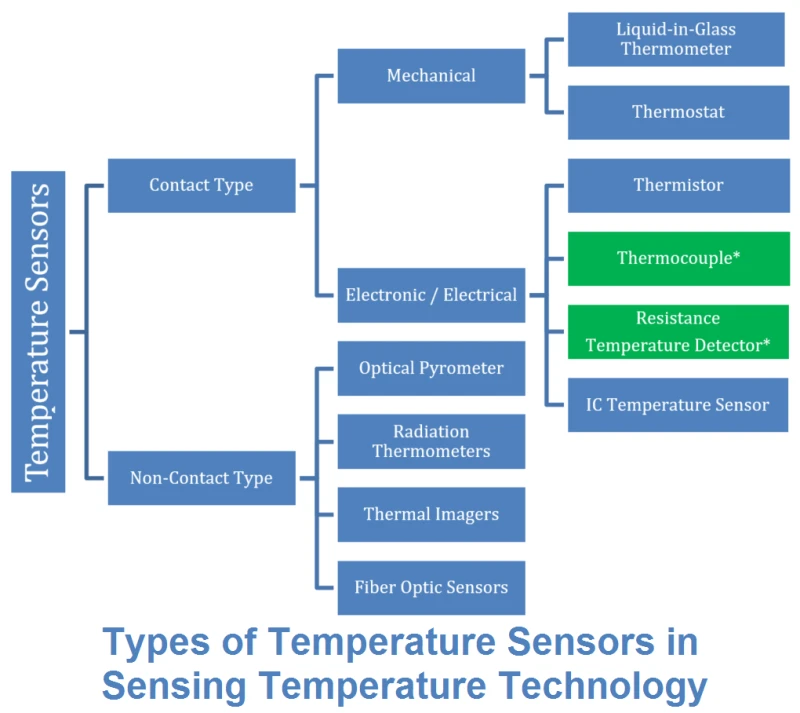

There are two primary types of temperature sensors based on their interaction with the object being measured: contact and non-contact sensors. Each type of sensor has unique applications that make them suitable for different environments and use cases.

Contact Temperature Sensors

Contact temperature sensors require direct contact with the material they are measuring. These include:

- Thermistors: Highly sensitive resistors that provide accurate readings over a limited temperature range (-50°C to 250°C). They are widely used in consumer electronics for precise temperature management. Sensing temperature using thermistors is highly effective in household appliances, such as refrigerators and washing machines.

- RTDs: RTDs use the resistance change in metals, often platinum, to measure temperature. They can accurately measure a broad range of temperatures (-200°C to 600°C). RTDs are commonly used in industrial applications where precise sensing temperature is required, such as in chemical processing and power generation.

- Thermocouples: These sensors consist of two dissimilar metals joined at one end, generating a voltage that varies with temperature. Although they can measure a broad temperature range (-200°C to 1750°C), they are generally less accurate compared to thermistors and RTDs. Thermocouples are widely used by sensor manufacturers for applications that require a wide temperature range, such as in furnaces and gas turbines.

Non-Contact Temperature Sensors

Non-contact temperature sensors measure temperature without direct contact, often utilizing infrared radiation. This makes them ideal for use in hazardous or hard-to-reach environments. Common types include:

- Infrared Sensors: These sensors measure thermal radiation emitted by objects, allowing for safe temperature monitoring from a distance. They are commonly used in industrial applications where contact sensors may not be practical. Sensing temperature using infrared sensors is crucial in scenarios such as monitoring moving machinery or high-temperature furnaces.

-

Applications of Temperature Sensors

Temperature sensors are widely used in modern technology, with diverse applications across various fields. The ability to accurately sense temperature is crucial in many industries, ensuring that processes run smoothly and safely.

Household Appliances

In household appliances, temperature sensor ensures efficient operation by accurately managing temperature in devices like microwaves, refrigerators, and ovens. This prevents overheating and contributes to energy efficiency. Sensing temperature in these appliances is vital for ensuring food safety and maintaining optimal cooking conditions.

Automotive Systems

Automotive systems use temperature sensors to monitor engine temperature and ensure optimal performance. These sensors help manage heat levels, extending the lifespan of vehicle components and improving fuel efficiency. Sensing temperature in the automotive industry also plays a role in climate control systems, ensuring passenger comfort.

Medical Devices

Temperature sensor is critical in medical equipment for maintaining accurate body temperature readings. Devices like incubators and dialysis machines rely on precise temperature sensing to ensure patient safety. Accurate sensing temperature is essential in healthcare settings, as even minor temperature variations can significantly impact patient outcomes.

Industrial Systems

In industrial settings, temperature sensors are essential for monitoring processes in HVAC systems, power plants, and manufacturing environments. Maintaining optimal temperatures is crucial for safety and operational efficiency. Sensing temperature in industrial processes helps prevent equipment failures and ensures consistent product quality.

HVAC Systems

Sensing temperature accurately is crucial for HVAC (Heating, Ventilation, and Air Conditioning) systems. Temperature sensor in HVAC systems helps regulate indoor climate, ensuring comfort and energy efficiency. Leading sensor manufacturers design specialized sensors for HVAC applications to maintain precise temperature control in both residential and commercial buildings.

Consumer Electronics

The sensing temperature capability of modern temperature sensors is also evident in consumer electronics, such as smartphones, tablets, and wearable devices. These sensors help prevent overheating and maintain the safe operation of electronic components. Sensor manufacturers have developed compact temperature sensor to fit into the limited space available in these devices while still providing accurate readings.

Advanced Technologies in Temperature Sensing

With advancements in technology, sensing temperature has become even more accurate and reliable. Sensor manufacturers are incorporating new materials and technologies to enhance the performance of temperature sensors across various applications.

Wireless Temperature Sensor

Wireless temperature sensor has become increasingly popular, especially in industrial and healthcare settings. This sensor allows for remote sensing temperature monitoring, providing real-time data without the need for extensive wiring. This is particularly beneficial in large facilities where wired sensors would be impractical.

Smart Temperature Sensor

Smart temperature sensor is designed to integrate with IoT (Internet of Things) systems. It provides data that can be analyzed to improve efficiency and predict potential issues before they become critical. Sensing temperature through smart sensors is crucial in predictive maintenance, where early detection of temperature anomalies can prevent costly downtime.

Flexible Temperature Sensor

Flexible temperature sensors are a recent innovation, allowing sensing temperature on curved or uneven surfaces. These sensors are especially useful in wearable technology and healthcare, where they can be used to monitor body temperature comfortably and accurately. Sensor manufacturers are exploring new materials, such as flexible polymers, to enhance the adaptability of these sensors.

Challenges in Sensing Temperature

Despite the advancements in sensing temperature, there are still challenges that sensor manufacturers face. These challenges include ensuring sensor accuracy in extreme environments, dealing with sensor drift over time, and minimizing the impact of external factors such as humidity and electromagnetic interference.

Environmental Factors

Environmental conditions can significantly affect the accuracy of temperature sensors. For instance, high humidity or dust can interfere with sensor readings. Sensing temperature accurately in such conditions requires careful sensor selection and, in some cases, protective housing to shield the sensor from external elements.

Calibration

Calibration is crucial for maintaining the accuracy of temperature sensors. Over time, sensors can drift, leading to inaccurate readings. Regular calibration ensures that the sensing temperature remains precise, which is especially important in applications like healthcare and industrial processes where accuracy is critical.

Conclusion

Sensing temperature is a fundamental aspect of modern technology, allowing for efficient and safe operation across many sectors. From household appliances to industrial equipment, temperature sensors provide precise and timely information that helps in effective decision-making and control. Leading sensor manufacturers continue to innovate, providing advanced tempe sensing solutions that meet diverse needs in an ever-evolving technological landscape. The role of temperature sensor is only expected to grow as technology advances, making sensing temperature an integral part of our future.

FAQs Section

What are temperature sensors used for?

Temperature sensors are used to detect and measure temperature changes in various applications. They are commonly found in household appliances, medical devices, automotive systems, and industrial equipment. Sensing temperature accurately is crucial for ensuring safety and efficiency in these applications.

What is the principle behind temperature sensors?

Most temperature sensors operate based on the change in electrical properties with temperature. These changes can be measured in terms of voltage or resistance, which is then converted into a readable temperature value. Sensing temperature through these principles allows for accurate and reliable monitoring.

What types of temperature sensors exist?

Temperature sensors can be divided into two main categories: contact and non-contact sensors. Contact sensors like thermistors, RTDs, and thermocouples require physical contact, while non-contact sensors, like infrared sensors, use thermal radiation. Each type is suitable for different sensing temperature requirements based on the application.

How do thermistors work?

Thermistors are temperature-sensitive resistors. In NTC thermistors, resistance decreases as temperature increases, providing a precise reading of temperature changes. Sensing temperature with thermistors is effective for applications requiring high sensitivity.

How do sensor manufacturers ensure accuracy?

Sensor manufacturers ensure accuracy by using high-quality materials, precise calibration processes, and protective housing to shield sensors from environmental factors. Regular calibration and testing are crucial for maintaining the accuracy of temperature sensors.

For more information about NTC Temperature Sensor MF52E, visit our detailed product page.

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

Price and Payment

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

You may also like

Temp. Sensor for coffee machine

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd