How to Test a Thermistor: Comprehensive Guide for NTC and PTC Thermistors

Discover the essential steps for testing a thermistor in our comprehensive guide by DXM. Whether you're dealing with NTC or PTC thermistors, our expert insights help you understand their functionality and ensure accurate temperature measurements. Learn how to test a thermistor effectively to enhance your technical knowledge and resolve potential issues. Dive into the detailed explanations and practical advice tailored for seamless integration into your projects. Stay informed and maintain efficiency with DXM’s reliable guidance.

- How to Test a Thermistor Including NTC Thermistors and PTC Thermistors for Reliable Performance

- Understanding NTC Thermistors and PTC Thermistors

- NTC Thermistors

- PTC Thermistors

- Essential Tools for Testing NTC Thermistors and PTC Thermistors

- Best Practices for Testing Thermal Resistors

- How to Test a Thermistor: Step-by-Step Guide for testing NTC and PTC Thermistors

- Introduction to Testing Thermal Resistors

- Step-by-Step Guide: Testing NTC Thermistors

- Step-by-Step Guide: Testing PTC Thermistors

- Best Practices for Testing Thermal Resistors

- Safety Tips When Testing NTC and PTC Thermistors

- Troubleshooting Common Issues with Thermal Resistors

- Advanced Testing Techniques for Thermal Resistors

- FAQs:How to Test a Thermistor

- Conclusion: Ensuring Reliable Thermistor Performance

How to Test a Thermistor Including NTC Thermistors and PTC Thermistors for Reliable Performance

Understanding how to test a thermistor is vital for maintaining electronic devices. Thermistors come in two types: NTC Thermistors and PTC Thermistors. They also known as Thermal Resistors.Whether you’re dealing with ntc vs ptc thermistor, knowing how to test them ensures your systems perform reliably. This guide covers thermistor types, necessary equipment, and step-by-step testing procedures.

Understanding NTC Thermistors and PTC Thermistors

Thermistors are thermal resistors used in various applications. They act as temperature sensors or temperature-dependent resistors. There are two main types:

NTC Thermistors

NTC Thermistors (Negative Temperature Coefficient) decrease in resistance as temperature rises. They are ideal for temperature sensing and control in circuits.

PTC Thermistors

PTC Thermistors (Positive Temperature Coefficient) increase in resistance with temperature. They are commonly used for overcurrent protection and as resettable fuses.

Both types ensure electronic systems remain stable and safe by accurately responding to temperature changes.

Essential Tools for Testing NTC Thermistors and PTC Thermistors

To understand how to test a thermistor, it's important to have right tools. Thermal Resistors, including both NTC Thermistors and PTC Thermistors, require accurate testing to ensure proper functionality. Below are the essential tools for testing Thermal Resistors.

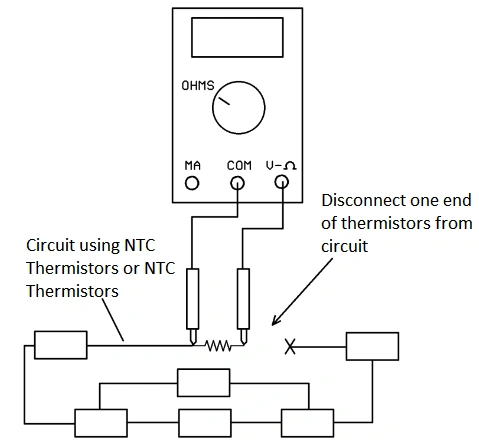

1. Multimeter or Ohmmeter

A multimeter is essential for measuring the resistance of Thermal Resistors. Most multimeters have an ohmmeter function, which can accurately measure the resistance of both NTC Thermistors and PTC Thermistors. Ensure the multimeter is capable of measuring the thermistor’s resistance range, which can vary from a few ohms to several megaohms.

2. Heating Device

To test how the thermistor reacts to temperature changes, a heating device is required. A heat gun or hairdryer works well for applying controlled heat to the thermistor. You can also use a hot water source, but be cautious to avoid damage if the thermistor is not designed for immersion. Controlled heating allows for accurate testing of the temperature-resistance relationship.

Best Practices for Testing Thermal Resistors

- Use secure connections to prevent inaccurate readings.

- Gradually apply heat to avoid damaging the thermistor.

- Always compare results to the manufacturer’s specifications to ensure accuracy.

By having the proper equipment, you can confidently perform tests on NTC Thermistors and PTC Thermistors, ensuring their functionality and reliability in your electronic systems.

How to Test a Thermistor: Step-by-Step Guide for testing NTC and PTC Thermistors

Introduction to Testing Thermal Resistors

Knowing how to test a thermistor is essential for ensuring the proper functionality of your devices. Whether you're testing NTC Thermistors or PTC Thermistors, this process ensures that your thermistor responds correctly to temperature changes. Below is a simple guide to testing both types of Thermal Resistors.

Step-by-Step Guide: Testing NTC Thermistors

Step 1: Initial Resistance Measurement

- Set your multimeter to measure resistance (ohms).

- Connect the multimeter probes to the NTC thermistor's terminals.

- Measure the thermistor's resistance at room temperature.

- The reading should be close to the rated value (e.g., 10KΩ).

Step 2: Apply Heat

- Gradually apply heat using a heating device, such as a hairdryer.

- Monitor the resistance reading on your multimeter.

Step 3: Interpret the Results

- The resistance should decrease as the temperature rises.

- If the resistance remains constant or increases, the thermistor may be faulty.

Step-by-Step Guide: Testing PTC Thermistors

Step 1: Initial Resistance Measurement

- Set your multimeter to resistance mode.

- Measure the PTC thermistor’s resistance at room temperature.

- The reading should show a low resistance value.

Step 2: Apply Heat

- Use a heat source to warm the PTC thermistor.

- Keep the multimeter connected and observe the resistance.

Step 3: Interpret the Results

- The resistance should increase steadily as the temperature rises.

- If there’s no change or an irregular reading, the thermistor might be defective.

Best Practices for Testing Thermal Resistors

When learning how to test a thermistor, following best practices ensures accurate results and protects your NTC Thermistors and PTC Thermistors from damage. These tips will help you test thermistor efficiently and safely.

-

Ensure Accurate Connections: Secure connections between the multimeter probes and the thermistor are essential for precise readings. Poor contact can lead to inaccurate measurements.

-

Apply Heat Gradually: To avoid thermal shock and potential damage to the thermistor, apply heat slowly and in a controlled manner. If possible, use a temperature-controlled environment.

-

Compare to Manufacturer’s Specifications: Always reference the thermistor’s datasheet for correct resistance values at various temperatures to verify functionality.

-

Consider Ambient Temperature: Ambient temperature can impact the initial resistance readings. Let the thermistor stabilize at room temperature before testing to get reliable results.

-

Follow Safety Guidelines: When using heating devices, follow safety procedures to prevent burns and protect your testing equipment.

By implementing these best practices, you can ensure reliable testing of both NTC Thermistors and PTC Thermistors, improving the accuracy of your results and extending the life of your devices.

Safety Tips When Testing NTC and PTC Thermistors

When learning how to test a thermistor, safety should be your top priority. Testing NTC Thermistors and PTC Thermistors involves handling electrical components and heat, which can pose risks if not done carefully. Follow these key safety tips to ensure a safe testing process.

- Avoid Overheating: Excessive heat can permanently damage thermistor. Use a controlled heat source and monitor temperatures carefully.

- Be Cautious of Burns: If using a heat gun or similar device, handle it carefully to avoid burns from high temperatures.

- Power Off the Circuit: Always ensure the circuit is powered off when testing thermistor to prevent electrical shocks.

- Dry and Safe Workspace: Keep your workspace dry and free from conductive materials to avoid short circuits and ensure safe testing conditions.

By following these safety guidelines, you can effectively and safely test both NTC Thermistors and PTC Thermistors, ensuring they function as expected without causing harm to yourself or the components.

Troubleshooting Common Issues with Thermal Resistors

When learning how to test a thermistor, it’s important to recognize common issues that may arise. Whether you’re working with NTC Thermistors or PTC Thermistors, troubleshooting ensures accurate results and proper thermistor functionality.

Inconsistent Resistance Readings

Inconsistent readings can result from poor connections, incorrect multimeter settings, or faulty Thermal Resistors. Check that all connections are secure and retest. Ensure your multimeter is correctly set to measure resistance.

Thermistor Not Responding to Temperature Changes

If the thermistor doesn't respond to heat, it may be damaged or improperly connected. Recheck the testing setup and ensure the thermistor is in good condition.

Advanced Testing Techniques for Thermal Resistors

Using a Wheatstone Bridge

For higher precision, a Wheatstone Bridge circuit provides more accurate resistance measurements. This method balances the circuit and improves the accuracy of thermistor testing.

Environmental Chamber Testing

For applications requiring stringent conditions, an environmental chamber can simulate different temperatures. This ensures that Thermal Resistors function reliably under specific environmental conditions.

By addressing common issues and utilizing advanced techniques, you can ensure reliable testing of NTC Thermistors and PTC Thermistors for your electronic systems.

FAQs:How to Test a Thermistor

How do I determine the thermistors's temperature range?

The temperature range is usually provided in the datasheet. For accurate testing, stay within these specified limits.

Can Thermal Resistors be repaired?

Generally,Thermal Resistors are not repairable due to their delicate nature. If faulty, replacement is advised.

What are the applications of NTC and PTC thermistor?

- **NTC Thermistors**: Widely used in temperature sensing and protection circuits.

- **PTC Thermistors**: Commonly found in heating elements and overload protection applications.

How accurate are Thermal Resistors readings?

Their accuracy depends on the quality and specification of the thermistor and proper calibration within the system.

Conclusion: Ensuring Reliable Thermistor Performance

Knowing how to test a thermistor is crucial for anyone working with electronic systems. Proper testing of both NTC Thermistors and PTC Thermistors ensures accurate temperature control and system reliability. By following these simple procedures, you can effectively determine if a thermal resistor is functioning properly or needs replacement.

Testing thermistor is straightforward with the right equipment and knowledge. Understanding how resistance changes with temperature allows you to maintain the performance and longevity of electronic devices. Regular testing of Thermal Resistors also helps in preventing system failures and ensures consistent operation.

Always refer to manufacturer specifications for the most accurate testing parameters. With practice, you’ll become proficient in assessing Thermal Resistors health, ensuring your temperature-dependent systems work efficiently for years to come.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Price and Payment

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

Logistics

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

You may also like

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Termistor PTC Thermistors MZ21 Series: Reliable Protection for Telecom Main Distribution Frame

PTC Electric Thermistors for telecom apparatus circuit protection (MZ23 series)

PTC Electronics MZ31 Series MZ8 Type: Reliable Overcurrent and Overload Protection Solutions

Negative Temperature Coefficient Thermistor for temperature compensation (MF11 series)

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd