PT100 temperature sensor Testing Guide

Learn how to effectively test PT100 temperature sensor using multimeters, calibration baths, and advanced systems. We cover troubleshooting common issues and FAQs to ensure accurate temperature readings and reliable system performance. Improve accuracy and reduce downtime!

- How to Test PT100 Temperature Sensor? A Comprehensive Guide

- Understanding the PT100 Temperature Sensor

- Methods for Testing PT100 Temperature Sensor

- Troubleshooting Common Issues with PT100 Temperature Sensor

- Frequently Asked Questions (FAQs)

- * Q: How often should I test my PT100 temperature sensors?

- * Q: What are the common causes of PT100 temperature sensor failure?

- * Q: Can I repair a faulty PT100 temperature sensor?

- * Q: What is the difference between a PT100 and a PT1000 temperature sensor?

- Conclusion

How to Test PT100 Temperature Sensor? A Comprehensive Guide

To accurately test a PT100 temperature sensor, it is essential to understand its application in industrial settings. PT100 temperature sensors offer reliable and precise temperature measurements. Knowing how to test PT100 temperature sensor ensures your systems remain accurate and efficient.

When testing PT100 temperature sensors, use a precise multimeter or a dedicated sensors tester. Check for resistance changes and verify sensor calibration. Regular testing can prevent temperature fluctuations and system failures. For accurate results, always follow manufacturer guidelines. Proper maintenance and calibration of PT100 temperature sensors will enhance performance and prolong their lifespan.

Understanding the PT100 Temperature Sensor

Before diving into testing procedures, let's briefly review the fundamentals of a PT100 temperature sensor. These sensors utilize a platinum resistor whose resistance changes predictably with temperature. The "PT100" designation signifies that the resistance is 100 ohms at 0°C. This consistent relationship allows for accurate temperature measurement across a wide range. Accurate calibration and testing of your PT100 temperature sensors are essential for maintaining this accuracy.

Methods for Testing PT100 Temperature Sensor

We recommend several methods for testing PT100 temperature sensors, each offering different levels of precision and complexity.

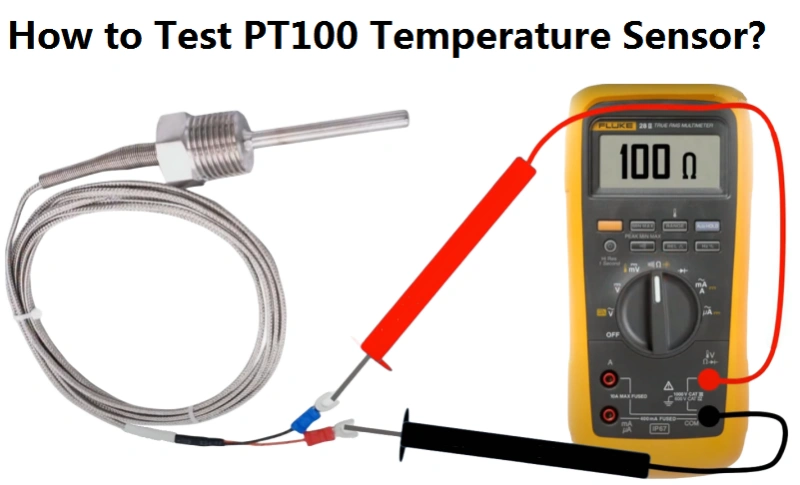

1. Using a Multimeter: This is the simplest method, suitable for a quick check of sensor continuity and approximate resistance.

* Procedure: Disconnect the PT100 sensor from the circuit. Using a multimeter set to ohms, measure the resistance across the sensor's terminals at room temperature. Compare the measured resistance to the expected value (approximately 100 ohms at 0°C, adjusting for ambient temperature using the PT100 resistance-temperature table). A significant deviation indicates a potential problem with the PT100 temperature sensors. This method provides only a basic check and cannot account for variations in the PT100 temperature sensors resistance-temperature profile.

2. Utilizing a Temperature Calibration Bath: This method offers significantly higher accuracy.

* Procedure: Immerse the PT100 temperature sensor in a calibrated temperature bath with known and stable temperatures. Using a precision multimeter or data acquisition system, measure the sensor's resistance at various temperatures within the sensor's operating range. Compare the measured resistances to the expected values based on the PT100 resistance-temperature relationship. Significant deviations indicate a need for recalibration or replacement of the PT100 temperature sensors.

3. Employing a Temperature Calibration System: For the highest accuracy and automation, dedicated temperature calibration systems are available.

* Procedure: These systems provide precise temperature control and automated measurement of the PT100 temperature sensor's resistance at multiple points. The collected data will allow for a comprehensive assessment of the sensor’s accuracy. This method ensures full compliance with quality standards and calibration protocols. These advanced systems allow for detailed analysis and reporting, crucial for quality assurance procedures. Remember, proper use and maintenance of your PT100 temperature sensors are crucial for maintaining accuracy.

Troubleshooting Common Issues with PT100 Temperature Sensor

During testing, you might encounter several issues. Here are some common problems and their solutions:

* Incorrect Readings: Verify proper wiring and connections. Check for damage to the sensor or its leads. Ensure the sensor is properly calibrated. Recalibration of the PT100 temperature sensor is often necessary to maintain accuracy. Consider environmental factors and potential electromagnetic interference.

* Broken Sensors: If you find an open circuit or a short circuit, the PT100 temperature sensors need replacement. Proper handling and storage prevent premature damage and failure.

* Drift: A gradual change in sensor readings might indicate aging or damage. Calibration or replacement may be necessary. Regular maintenance and calibration of the PT100 temperature sensors extend the useful life of the components.

Frequently Asked Questions (FAQs)

* Q: How often should I test my PT100 temperature sensors?

* A: The frequency depends on the application's criticality and the sensor's operating conditions. Regular testing—at least annually—is recommended, with more frequent checks in demanding environments.

* Q: What are the common causes of PT100 temperature sensor failure?

* A: Physical damage, aging, contamination, and improper installation are among the major causes.

* Q: Can I repair a faulty PT100 temperature sensor?

* A: Generally, no. PT100 temperature sensors are complex devices; repair is usually not cost-effective. Replacement is usually the most efficient solution.

* Q: What is the difference between a PT100 and a PT1000 temperature sensor?

* A: The primary difference is their resistance at 0°C. PT100 has 100 ohms, while PT1000 has 1000 ohms. This affects signal sensitivity and noise immunity. PT1000 sensors are often preferred in applications requiring higher resistance and better noise rejection.

Conclusion

Regular testing and maintenance of your PT100 temperature sensor are critical for accurate temperature control. Proper care ensures system reliability and minimizes downtime. By understanding how to test PT100 temperature sensor, you can improve its performance and longevity.

Investing in high-quality PT100 temperature sensors and calibration equipment enhances accuracy and prevents potential issues. Routine checks and calibration will reduce errors and ensure optimal functionality.

With the right tools and knowledge, you can maintain the reliability of your PT100 sensor. Contact us today to learn more about our PT100 temperature sensors and calibration services. We are here to help you achieve greater efficiency and system performance.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

Price and Payment

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

You may also like

PT100 Temperature Sensor - High Accuracy for Industrial Applications

Sensor PT100 SMD Introduction

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd