PTC Thermistor Material: Selection & Applications

This blog post dives deep into PTC thermistor material, covering composition, key characteristics, selection criteria, applications, and FAQs. Learn how to choose the optimal PTC thermistors for your design needs and enhance your product's performance.

- PTC Thermistor Material: A Deep Dive into Performance and Applications

- Understanding PTC Thermistor Material Composition

- Key Characteristics of PTC Thermistor Materials

- Selecting the Right PTC Thermistor Material for Your Application

- Common Applications of PTC Thermistors

- FAQs about PTC Thermistor Material

- Conclusion

PTC Thermistor Material: A Deep Dive into Performance and Applications

Choosing the right PTC thermistor material is crucial for optimal performance in your application. Understanding the properties of various PTC thermistors materials is key to successful design and integration. We'll explore the intricacies of PTC thermistor material selection, focusing on key characteristics and common applications.

Understanding PTC Thermistor Material Composition

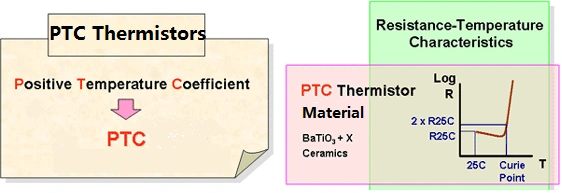

PTC thermistors, also known as positive temperature coefficient thermistors, are semiconductor devices exhibiting a significant increase in resistance above a specific characteristic temperature. The core of a PTC thermistor's functionality lies in its material composition. Common PTC thermistor materials include barium titanate (BaTiO₃) based ceramics. These materials are carefully formulated and processed to achieve the desired temperature-resistance characteristics. The precise composition of the Positive Temperature Coefficient thermistors material influences critical parameters like the switching temperature, resistance change, and overall stability. Variations in the dopants and processing techniques significantly alter the final properties of the PTC thermistors material. The selection of the right material is therefore paramount.

Key Characteristics of PTC Thermistor Materials

Several key characteristics define the performance of a PTC thermistor material. These include:

* Switching Temperature (Ts): This is the temperature at which the PTC thermistors material exhibits a rapid increase in resistance. Precise control over Ts is essential for specific applications. The PTC thermistor material's composition directly influences this critical parameter.

* Resistance Change (ΔR):The ratio of the high-temperature resistance to the low-temperature resistance signifies the effectiveness of the PTC thermistor. A higher resistance change indicates a more pronounced switching action. This parameter is directly related to the PTC thermistor material's formulation.

* Temperature Coefficient of Resistance (TCR): This parameter describes the rate of resistance change with temperature. A high TCR indicates a sharp resistance increase near the switching temperature, a key feature of effective PTC thermistors material. Careful control of the PTC thermistors material's composition allows for tailoring the TCR.

* Dissipation Factor: This is the ability of the PTC thermistor material to handle power without overheating. A higher dissipation factor allows for higher power applications. The PTC thermistor material's inherent properties, along with its physical design, determine its dissipation factor.

Selecting the Right PTC Thermistor Material for Your Application

The ideal PTC thermistor material for your application depends heavily on the specific requirements. Factors to consider include:

* Operating Temperature Range: The chosen PTC thermistors material must operate reliably within the intended temperature range. The switching temperature (Ts) of the PTC thermistors material needs careful consideration in this context.

* Power Dissipation: The PTC material must be capable of handling the power expected in the application. This often involves considering the dissipation factor and physical design of the device alongside the chosen PTC thermistors material.

* Size and Form Factor: The physical dimensions of the PTC thermistors are influenced by both the material and the manufacturing process. Selecting a suitable PTC thermistor material also dictates the available form factor.

* Environmental Conditions: The chosen PTC material must withstand the environmental conditions, such as humidity and vibration, it will experience.

Common Applications of PTC Thermistors

PTC thermistors find widespread use in various applications due to their unique temperature-sensitive resistance characteristics. These include:

* Overcurrent Protection: PTC thermistors are frequently used as inrush current limiters to protect sensitive electronics from excessive current surges during power-up. The chosen PTC thermistor material needs to be robust enough to withstand the high inrush currents.

* Temperature Sensing: While less common than NTC thermistors, some applications leverage the PTC thermistor material's sharp resistance change at a specific temperature for precise temperature sensing.

* Self-Regulating Heating Elements: The PTC effect enables self-regulating heating elements, where the resistance increase limits the power consumption as the temperature rises. Selecting the appropriate PTC thermistors material is crucial for achieving the desired heating profile.

* Motor Protection: Positive Temperature Coefficient thermistors act as thermal protection devices for motors, preventing damage from excessive heating. The selection of the PTC thermistor material is influenced by the motor's thermal characteristics.

* Automotive Applications: PTC thermistors are integral components in various automotive systems, including air conditioning, heating systems, and motor control circuits. Here, the reliable performance and robustness of the selected PTC thermistor material is paramount.

FAQs about PTC Thermistor Material

Q: What are the limitations of PTC thermistor materials?

A: While highly useful, PTC thermistors have limitations. Their resistance change is typically non-linear, and their response time might be slower than other temperature-sensing technologies. Furthermore, the long-term stability of the thermistor material can be affected by operating conditions.

Q: How is the lifespan of a PTC thermistor affected by its material composition?

A: The lifespan of a PTC thermistor is intricately linked to the stability of its material composition. High-quality materials and robust manufacturing processes contribute to improved longevity and reliability. Degradation mechanisms, such as aging and thermal cycling, can affect the performance of the thermistors material over time.

Q: Are there any environmental concerns associated with PTC thermistor materials?

A: Most commonly used PTC thermistors materials are relatively environmentally benign. However, responsible disposal is still important, following local regulations.

Conclusion

Selecting the appropriate PTC thermistor material is crucial for successful application design. We've explored the key characteristics of common PTC thermistors materials, highlighting their influence on device performance. We've also examined various applications and addressed common concerns. Understanding these factors empowers engineers to optimize their designs and leverage the unique benefits of PTC thermistors. Contact us today to discuss your specific application requirements and learn how we can help you find the perfect PTC thermistor solution!

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

Price and Payment

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

You may also like

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Termistor PTC Thermistors MZ21 Series: Reliable Protection for Telecom Main Distribution Frame

PTC Electric Thermistors for telecom apparatus circuit protection (MZ23 series)

PTC Electronics MZ31 Series MZ8 Type: Reliable Overcurrent and Overload Protection Solutions

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd