PTC Thermistor Resistance vs Temperature: A Comprehensive Guide

Explore DXM’s comprehensive guide on PTC thermistor resistance vs temperature. Understand how PTC thermistor properties change with temperature for precise applications. Perfect for engineers seeking reliable thermal sensing solutions. Stay informed with DXM’s expert insights.

- What is a PTC Thermistor?

- Understanding PTC Thermistor Resistance vs Temperature

- The Curie Temperature and Its Role in PTC Thermistor Resistance vs Temperature

- Practical Applications of PTC Thermistor Resistance vs Temperature Characteristics

- Factors Affecting PTC Thermistor Resistance vs Temperature Performance

- Material Composition and Its Impact on PTC Thermistor Resistance vs Temperature

- Environmental Conditions and Their Effect on PTC Thermistor Performance

- Manufacturing Precision and Its Role in PTC Thermistor Resistance vs Temperature

- Choosing the Right PTC Thermistor

- Application Requirements

- Compatibility with Other Components

- Cost and Availability

- DXM's Expertise in PTC Thermistor Manufacturing

- Advanced R&D Capabilities

- Quality Assurance

- Global Reach

- Conclusion

- Call to Action

Introduction In the world of electronics, understanding the relationship between PTC thermistor resistance vs temperature is crucial for optimizing the performance and reliability of your devices. At DXM, we have been at the forefront of manufacturing high-quality PTC thermistors for over 29 years, offering unparalleled expertise and innovative solutions. In this blog, we delve into the intricacies of PTC thermistor behavior, providing insights that can help you enhance your electronic designs.

What is a PTC Thermistor?

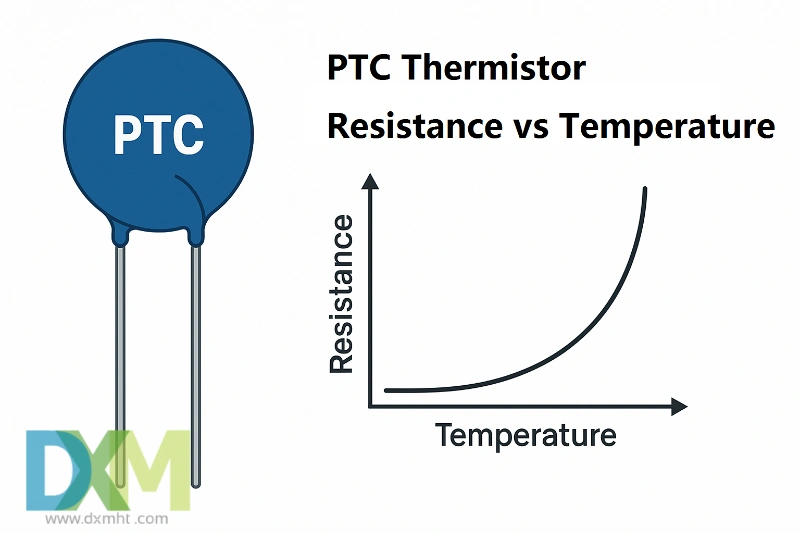

A Positive Temperature Coefficient (PTC) thermistor is a type of resistor whose resistance increases as the temperature rises. This unique characteristic makes PTC thermistors invaluable in applications where temperature control and overcurrent protection are critical. At DXM, we specialize in producing PTC thermistors that meet the highest standards of quality and reliability.

Understanding PTC Thermistor Resistance vs Temperature

The key to effectively utilizing a PTC thermistor lies in understanding its resistance vs temperature relationship. Unlike the NTC thermistor (Negative Temperature Coefficient), a PTC thermistor exhibits a sharp rise in resistance when the temperature surpasses the Curie point. This transition allows it to function as a self-regulating component, automatically adjusting resistance to stabilize the temperature.

The Curie Temperature and Its Role in PTC Thermistor Resistance vs Temperature

The Curie temperature is a critical factor for PTC thermistors. Below this temperature, the resistance stays relatively low and stable. However, once the temperature exceeds the Curie point, the resistance increases dramatically. This limits current flow and prevents overheating. At DXM, we engineer PTC thermistors with precise control over the Curie temperature, tailoring them for various applications.

Practical Applications of PTC Thermistor Resistance vs Temperature Characteristics

Knowing the PTC thermistor resistance vs temperature relationship enables their use in several applications:

-

Overcurrent Protection: PTC thermistors act as resettable fuses. When current exceeds safe limits, their increasing resistance limits the flow and prevents circuit damage.

-

Temperature Sensing: PTC thermistors are used in devices that require accurate temperature monitoring, such as medical equipment and automotive systems.

-

Heating Elements: PTC thermistors are commonly found in self-regulating heaters. They ensure consistent performance while enhancing safety.

By understanding the PTC thermistor resistance vs temperature characteristics, engineers can design more efficient and reliable systems across multiple industries. The ability to adjust resistance as temperature changes makes PTC thermistors a valuable tool for protecting circuits, sensing temperature, and ensuring safe heating.

Factors Affecting PTC Thermistor Resistance vs Temperature Performance

Several factors influence the performance of PTC thermistors, particularly their resistance vs temperature characteristics. At DXM, we understand these factors and ensure our products meet your precise needs.

Material Composition and Its Impact on PTC Thermistor Resistance vs Temperature

The material composition of PTC thermistors directly affects their resistance vs temperature behavior. We use advanced ceramic materials that ensure high stability. This guarantees consistent performance across a wide range of temperatures and conditions. Our products are engineered to meet the specific demands of various applications.

Environmental Conditions and Their Effect on PTC Thermistor Performance

Environmental factors, such as humidity and ambient temperature, play a significant role in PTC thermistor performance. These conditions can alter the resistance vs temperature relationship. At DXM, we rigorously test our PTC thermistors to ensure they maintain accuracy and reliability, even in challenging environments.

Manufacturing Precision and Its Role in PTC Thermistor Resistance vs Temperature

The precision of the manufacturing process is critical for consistent PTC thermistor performance. Small variations in the production process can affect the resistance vs temperature curve. At DXM, we adhere to ISO 9001:2008 standards, ensuring high precision at every stage of production. This commitment to quality guarantees that our PTC thermistors perform reliably in various applications.

By understanding and controlling these factors, we ensure that our PTC thermistors provide stable and accurate resistance vs temperature characteristics, which are crucial for their applications in overcurrent protection, temperature sensing, and heating elements.

Choosing the Right PTC Thermistor

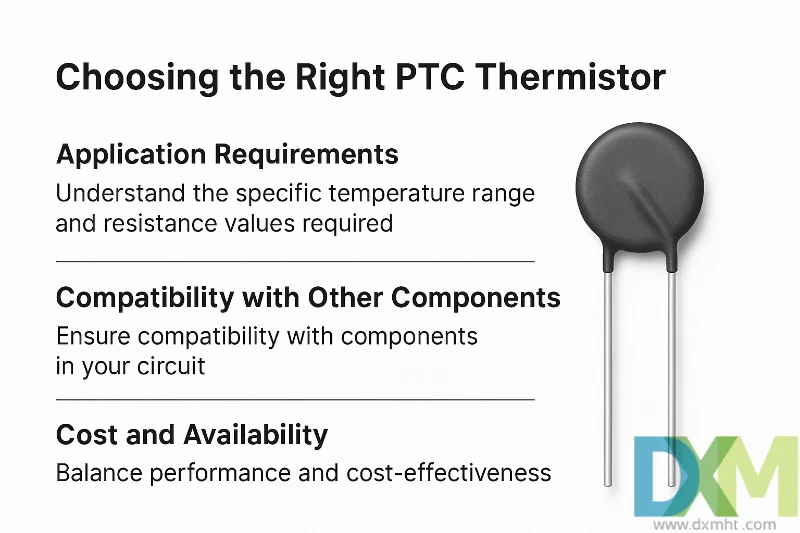

Selecting the appropriate PTC thermistor for your application involves considering several key factors:

Application Requirements

Understand the specific temperature range and resistance values required for your application. At DXM, we offer a diverse range of PTC thermistors designed to meet various needs, from automotive to consumer electronics.

Compatibility with Other Components

Ensure that the PTC thermistors you choose is compatible with other components in your circuit. Our experts can help you select the right thermistor to ensure seamless integration and optimal performance.

Cost and Availability

Balancing cost and performance is essential. DXM provides cost-effective solutions without compromising on quality, ensuring that you have access to the thermistors you need when you need them.

DXM's Expertise in PTC Thermistor Manufacturing

With over 28 years of experience in the electronics industry, DXM stands as a leader in PTC thermistors manufacturing. Our commitment to research and development ensures that we stay at the forefront of technological advancements, offering innovative solutions that meet the evolving needs of our customers.

Advanced R&D Capabilities

Our state-of-the-art R&D facilities enable us to develop cutting-edge PTC thermistors tailored to specific applications. We continuously explore new materials and technologies to enhance the performance and reliability of our products.

Quality Assurance

At DXM, quality is our top priority. Our rigorous testing and quality control processes ensure that every PTC thermistor we produce meets the highest standards. We are proud of our ISO 9001:2008 certification, which underscores our dedication to excellence.

Global Reach

We serve a diverse range of industries, including automotive, consumer electronics, and telecommunications. Our global network allows us to deliver high-quality PTC thermistors to customers worldwide, ensuring that you have access to the best solutions no matter where you are.

Conclusion

Understanding the relationship between PTC thermistor resistance vs temperature is essential for leveraging these components effectively in your electronic designs. At DXM, our 28 years of industry expertise and commitment to quality ensure that you receive the best PTC thermistors for your applications. Whether you need overcurrent protection, temperature sensing, or heating solutions, we have the products and knowledge to help you succeed.

Call to Action

Explore the benefits of using PTC thermistors from DXM and enhance the performance and reliability of your electronic devices. Contact us today to learn more about our products and how we can support your next project.

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Updated on 20th June 2025

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Logistics

Shipment

1)Small order quantity and small packing:cargo may be arranged by courier;

2)Bulk order and big volume:shipment may be arranged by sea or by air as per customer’s requirements on FOB, C&F,CIF or LCL terms and do prompt shipment which is very important for our customers, so we do this matter seriously and we may arrange our shipment in time due to our rich experiences in this line. We may also accept the shipment on the term of freight prepaid or freight collect.

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Price and Payment

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

You may also like

PTC Resistors MZ71 Degauss Thermistor for TV monitor Degaussing

PTC Thermistor TV Degausser-Reliable MZ73 | DXM

PTC Elements for Telecom Termination MZ24 Series | DXM

PTC Termistor MZ31 Series: Reliable Overload Protection for Circuit Applications

PTC Thermal Resistor 19P for Overcurrent and Overload Protection

Linear PTC Thermistor Precision Temperature Sensing (KTY Series)

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd