Understanding Sensor Thermal: Your Guide to Thermal Heat Sensors

Navigate the world of sensor thermal technology through this detailed guide, uncovering the profound impact of thermal heat sensors on safety, efficiency, and cost-effectiveness in various industries.

- 1. What is Sensor Thermal Technology?

- 2. Common Types of Thermal Heat Sensors

- 3. How Thermal Heat Sensors Work

- 4. Applications of Sensor Thermal Technology

- 5. Advancements in Thermal Heat Sensor Technology

- 6. Benefits of Using Sensor Thermal Technology

- 7. Challenges and Solutions in Sensor Thermal Implementation

- 8. Selecting the Right Thermal Heat Sensor

- Conclusion

- Call to Action

- Summary

- FAQs

- Q1: What industries benefit most from thermal heat sensors?

- Q2: How do thermal heat sensors save energy?

- Q3: What improvements are on the horizon for thermal sensor technology?

In the fast-paced world of technology, "sensor thermal" isn't just a buzzword; it's a cornerstone of innovation, particularly in industries that prioritize safety, efficiency, and precision. When we speak of a thermal heat sensor, we're talking about a device that has transitioned from a simple gadget to a critical component in various fields. This article delves deep into the intricacies of sensor thermal technology, helping professionals like us understand its application, benefits, and evolution. By the end, you’ll see how these sensors are indispensable in today’s technology-driven landscape.

1. What is Sensor Thermal Technology?

Sensor thermal technology revolves around detecting temperature changes through thermal heat sensors. These sensors convert thermal energy into an electronic signal, providing precise temperature readings. Such technology is vital in machinery and environments where temperature plays a crucial role.

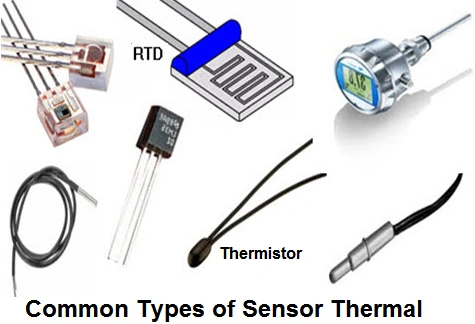

2. Common Types of Thermal Heat Sensors

- Thermocouples: Known for their broad temperature range and adaptability, thermocouples are used in everything from household appliances to industrial machinery.

- Resistance Temperature Detectors (RTDs):These sensors offer high accuracy and repeatability, making them ideal for laboratory and medical applications.

- Infrared Sensors: Perfect for non-contact temperature assessment, infrared sensors are essential in environments where direct sensor contact is not feasible.

3. How Thermal Heat Sensors Work

A thermal heat sensor operates by measuring the radiant energy of objects within its vicinity. It converts this data into an electronic signal, which is subsequently processed to yield a temperature reading. This process allows for quick and accurate assessments, crucial in high-stakes scenarios.

4. Applications of Sensor Thermal Technology

- Industrial Safety: In manufacturing, thermal sensors monitor equipment to prevent overheating, reducing accident risks.

- Medical Field: Devices like infrared thermometers enable quick patient assessments without physical contact, safeguarding both patients and healthcare workers.

- Automotive Industry: Modern vehicles employ these sensors for climate control and engine management, enhancing fuel efficiency and safety.

- Home Automation: Thermal sensors help create energy-efficient smart homes by managing heating and cooling systems intelligently.

5. Advancements in Thermal Heat Sensor Technology

Recent years have seen significant advancements, including miniaturization and enhanced sensitivity. Innovations such as printed thermal sensors and flexible options enable applications previously thought impossible, expanding their utility in sectors like wearable technology and robotics.

6. Benefits of Using Sensor Thermal Technology

- Precision and Accuracy: Advanced sensors offer unparalleled accuracy, reducing errors and improving process outcomes.

- Energy Efficiency: By optimizing temperature control, these sensors significantly cut down on energy consumption.

- Cost-Effective Maintenance: Predictive maintenance enabled by thermal sensors minimizes equipment downtime, saving costs in the long run.

7. Challenges and Solutions in Sensor Thermal Implementation

While thermal heat sensors technology presents numerous advantages, challenges like interference from environmental factors and sensors calibration persist. Solutions include robust sensor shielding and the development of self-calibrating models to ensure consistent performance across varied conditions.

8. Selecting the Right Thermal Heat Sensor

Choosing the appropriate sensor depends on factors such as temperature range, environment, and accuracy requirements. Understanding these criteria ensures the sensor meets the specific demands of your application.

Conclusion

Sensor thermal technology is carving a niche in several industries by enhancing accuracy and efficiency. Understanding the types, applications, and benefits is vital for any professional aiming to leverage these innovative technologies. As sensor technology continues to advance, the future holds even more potential for optimizing and revolutionizing how we measure and respond to thermal changes.

Call to Action

Embrace thermal technology today and unlock its full potential in your field. Contact us to explore how incorporating cutting-edge sensor solutions can enhance your systems, improve safety, and drive efficiency.

Summary

Navigate the world of sensor thermal technology through this detailed guide, uncovering the profound impact of thermal heat sensors on safety, efficiency, and cost-effectiveness in various industries.

FAQs

Q1: What industries benefit most from thermal heat sensors?

Industries like manufacturing, healthcare, automotive, and home automation significantly benefit, seeing improvements in safety, efficiency, and cost savings.

Q2: How do thermal heat sensors save energy?

By providing precise temperature data, these sensors enable optimal heating and cooling control, thus reducing excessive energy consumption.

Q3: What improvements are on the horizon for thermal sensor technology?

Future enhancements include increasing sensor sensitivity, developing flexible sensor applications, and integrating with IoT for smarter automation systems.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Price and Payment

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

You may also like

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd