Thermistor PTC Applications Explain What are PTC Thermistors Used For?

Learn about PTC thermistors, their unique properties, and diverse applications in overcurrent protection, temperature sensing, and more. Discover how to select the right thermistor PTC for your project and enhance your designs with superior safety and reliability.

- Understanding Thermistor PTC Characteristics

- Key Applications of Thermistor PTC

- 1. Overcurrent Protection:

- 2. Temperature Sensing:

- 3. Thermal Protection in Motors:

- 4. Automotive Applications:

- 5. Heating Elements:

- Selecting the Right Thermistor PTC

- FAQs about Thermistor PTC

- Q: How do PTC thermistors differ from NTC thermistors?

- Q: Is PTC thermistor reliable?

- Q: What are the limitations of PTC thermistors?

- Conclusion

- Call to Action:

A thermistor PTC is a type of thermistor that increases its resistance as temperature rises. This device is widely used in applications where temperature regulation is crucial. PTC thermistors are commonly found in overcurrent protection, temperature sensors, and self-regulating heating systems. Their ability to respond to temperature changes makes them ideal for ensuring the safety and efficiency of electronic devices. In welding equipment, for example, Thermistor PTC helps control temperature and prevent overheating. Understanding what PTC thermistors are used for can help you leverage their unique properties in various industries.

Understanding Thermistor PTC Characteristics

PTC thermistors, also known as positive temperature coefficient thermistors, exhibit a sharp rise in resistance above a specific temperature, their Curie temperature. This distinct characteristic makes them ideal for a wide range of applications requiring precise temperature control and protection. Their self-regulating nature and simple design contribute to their popularity and cost-effectiveness. The core functionality of a PTC thermistor is centered around its resistance change in relation to temperature. This change is highly predictable, making them valuable components in various circuits. Knowing the precise behavior of the PTC thermistor is key to selecting the right one for specific applications.

Key Applications of Thermistor PTC

The unique properties of PTC thermistors translate into several crucial applications. Let's explore some key areas where these components play a significant role:

1. Overcurrent Protection:

One of the most prevalent uses for PTC resistors is in overcurrent protection circuits. Their inherent ability to sharply increase resistance when exposed to excessive current prevents damage to sensitive electronics. In this application, the PTC thermistor acts as a self-resetting fuse, simplifying circuit design and maintenance. This makes Thermistor PTC an invaluable component in protecting circuits from overcurrent surges. The advantages of using PTC thermistors for overcurrent protection include their ability to automatically reset once the temperature decreases.

2. Temperature Sensing:

While primarily known for their overcurrent protection capabilities, PTC thermistors can also be used for temperature sensing applications. Although not as precise as some dedicated temperature sensors, their simplicity and cost-effectiveness make them attractive for basic temperature monitoring tasks. Careful calibration is required to ensure accurate measurements when using Thermistor PTC for temperature sensing. PTC thermistors provide a reliable and relatively inexpensive solution for basic temperature measurement needs.

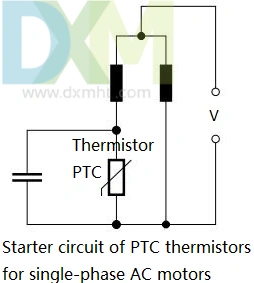

3. Thermal Protection in Motors:

PTC thermistors are frequently integrated into motor windings to provide thermal protection. By monitoring the temperature of the motor windings, they can quickly detect and respond to overheating conditions, preventing potential damage or even fires. This application highlights the safety features provided by Thermistor PTC. The use of PTC thermistors offers a safe and effective way to safeguard motors from thermal damage.

4. Automotive Applications:

The automotive industry utilizes PTC thermistors extensively. From controlling the temperature in various vehicle components to providing safety features, these devices are essential parts of modern vehicles. Specifically, Thermistor PTC is employed in the automotive industry for tasks ranging from engine management to air conditioning. PTC resistors, because of their reliability and effectiveness in diverse temperature conditions, are an integral part of automotive systems.

5. Heating Elements:

In some applications, PTC thermistors can even act as heating elements themselves. Their ability to generate heat at a specific temperature makes them suitable for various heating needs. These PTC thermistor heating elements can be used in a variety of applications with specific temperature requirements. The self-limiting temperature characteristic of Thermistor PTC adds a safety factor to this application. PTC thermistors provide an efficient and safe way to deliver controlled heating.

Selecting the Right Thermistor PTC

Choosing the appropriate PTC thermistor depends on the specific application and required specifications. Factors to consider include the required operating temperature, current rating, and the desired response time. It is crucial to carefully review the datasheet for each PTC resistor to ensure it meets your specific needs. Consult with a thermistor specialist for any doubts in selecting the appropriate PTC thermistor for your needs. Careful selection ensures optimal performance and reliability of your design.

FAQs about Thermistor PTC

Q: How do PTC thermistors differ from NTC thermistors?

A: PTC thermistors exhibit a *positive* temperature coefficient, meaning their resistance increases with temperature. NTC thermistors, conversely, have a *negative* temperature coefficient, meaning their resistance decreases with temperature. This fundamental difference leads to their distinct applications.

Q: Is PTC thermistor reliable?

A: PTC resistor is known for its reliability and long lifespan, provided it is used within its specified operating parameters. Proper selection and implementation are crucial for ensuring reliable operation.

Q: What are the limitations of PTC thermistors?

A: While highly versatile, PTC thermistors have limitations. Their temperature sensitivity can be affected by environmental factors, and they may not be suitable for applications requiring highly precise temperature control.

Conclusion

Thermistor PTC component offers a range of benefits across industries, thanks to its self-regulating properties and overcurrent protection. This thermistor is crucial in ensuring safe and efficient circuit design. Its ability to adapt to temperature changes makes it ideal for various systems, including those requiring temperature control. PTC thermistors are widely used in applications such as welding machines, power supplies, and safety devices. Understanding what PTC thermistors are used for enables better design and increased reliability in electronics.

Call to Action:

Want to enhance your project with the reliability of PTC thermistors? Contact us now to find the best solution tailored to your needs.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

Shipment

1)Small order quantity and small packing:cargo may be arranged by courier;

2)Bulk order and big volume:shipment may be arranged by sea or by air as per customer’s requirements on FOB, C&F,CIF or LCL terms and do prompt shipment which is very important for our customers, so we do this matter seriously and we may arrange our shipment in time due to our rich experiences in this line. We may also accept the shipment on the term of freight prepaid or freight collect.

Customized Services

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

You may also like

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Thermistor PTC Resistors TV degausser - High Stability MZ72

PTC Thermistor TV Degausser-Reliable MZ73 | DXM

Termistor PTC Thermistors MZ21 Series: Reliable Protection for Telecom Main Distribution Frame

PTC Electric Thermistors for telecom apparatus circuit protection (MZ23 series)

PTC Elements for Telecom Termination MZ24 Series | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd