Ceramic Heating Element: Applications & Benefits

Discover the power and versatility of ceramic heating element. Learn about its construction, applications, and advantages in various industries. Improve efficiency and reliability with DXM's high-quality ceramic heater element.

- What is a Ceramic Heater? Understanding Ceramic Heating Element and Applications

- Understanding Ceramic Heating Element Construction and Functionality

- Diverse Applications of Ceramic Heating Element

- Selecting the Right Ceramic Heating Element for Your Application

- Advantages of Using Ceramic Heating Elements and Ceramic Heater Elements

- Frequently Asked Questions (FAQs)

- Q: What is the difference between a ceramic heating element and a ceramic heater element?

- Q: How long do ceramic heating elements last?

- Q: Can ceramic heating elements be repaired?

- Q: Are ceramic heating elements energy efficient?

- Q: What are the safety considerations when using ceramic heating elements?

- Conclusion

What is a Ceramic Heater? Understanding Ceramic Heating Element and Applications

A ceramic heating element is a key component in ceramic heaters. These elements are widely used due to their energy efficiency and durability. Ceramic heater element converts electrical energy into heat, making it ideal for home appliances and industrial applications. Its design ensures even heat distribution, making it effective for various heating needs. Whether for portable space heaters or industrial machines, ceramic heating element provides reliable, long-lasting performance.

Understanding Ceramic Heating Element Construction and Functionality

| Factor | Details |

|---|---|

| Material | A ceramic heating element uses high-quality alumina as its base material. This ensures excellent insulation and high-temperature resistance. |

| Heating Element | The ceramic heater element incorporates an electrically conductive metal alloy. This alloy generates heat when electricity passes through it. |

| Heat Distribution | The ceramic heating element effectively disperses heat, providing consistent and even temperature distribution. This ensures uniform heating across the surface. |

| Durability | With its robust construction, the ceramic heater element ensures long-lasting performance. It maintains high efficiency even in challenging environments. |

| Performance Factors | The performance of a ceramic heating element depends on the material used, element geometry, and the type of conductive material. These factors determine the heat output and efficiency. |

| Applications | Ceramic heater elements cater to specific applications. Some are designed for quick heating, while others are for long-term use at stable temperatures. |

| Selection Criteria | Choosing the right ceramic heater element depends on the application needs. Consider heat output, temperature stability, and lifespan when making a selection. |

Diverse Applications of Ceramic Heating Element

The versatility of ceramic heating element is a key factor in its widespread use. This component is essential in various industries:

* Home Appliances: Ceramic heater element is commonly found in many household appliances, including electric ovens, toasters, and hair dryers. Its efficiency and ability to reach high temperatures make it ideal for cooking and heating applications. The consistent heat distribution provided by a ceramic heater element ensures even cooking and prevents hot spots.

* Industrial Processes: In industrial settings, ceramic heater element plays a crucial role in processes like curing, drying, and thermal processing. Its robustness and ability to withstand high temperatures and harsh environments make it ideal for industrial applications. It is often used in specialized equipment, such as furnaces, kilns, and molding machines, where precise temperature control is paramount.

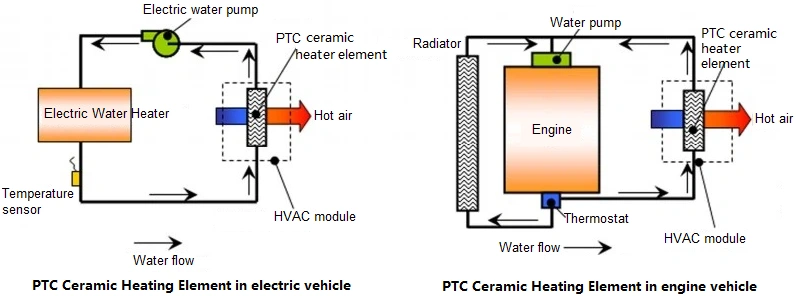

* Automotive Industry: The automotive sector utilizes ceramic heating element in applications such as seat heaters, defrost systems, and engine pre-heating. This component need to be both compact and efficient, meeting the demands of the automotive industry. The durable nature of a ceramic heater element ensures long-term reliability within the often demanding environment of a vehicle.

* Medical Devices: Certain medical devices utilize ceramic heating elements in their design, requiring strict safety and regulatory compliance. Precise temperature control is paramount in these applications. The reliable performance and consistent heat distribution of ceramic heating elements are critical for ensuring the safe and effective operation of these devices.

Selecting the Right Ceramic Heating Element for Your Application

Choosing the appropriate ceramic heating element or ceramic heater element requires careful consideration of several factors. These include:

* Required Power Output: This depends on the application's heating requirements.

* Operating Temperature: The maximum operating temperature of the element must exceed the application's peak temperature.

* Physical Dimensions and Mounting: The size and shape of the element must be compatible with the available space.

* Environmental Conditions: The operating environment's humidity, dust levels, and other factors can influence element selection.

Lifespan and Reliability: A long lifespan and reliable performance are essential in most applications.

We strongly suggest consulting with experienced engineers to determine the optimal ceramic heating element for your specific needs. Our team of experts can assist you in selecting the ideal component to meet your project’s unique requirements.

Advantages of Using Ceramic Heating Elements and Ceramic Heater Elements

Ceramic heating elements offer several key advantages:

* High Efficiency: They convert a high percentage of electrical energy into heat, minimizing energy waste.

* Long Lifespan: Their durable construction ensures extended operational life, reducing replacement costs.

* Precise Temperature Control: They allow for accurate temperature regulation, crucial for many applications.

* Uniform Heat Distribution: They deliver consistent heat, preventing hot spots and ensuring even heating.

* Safety: They are typically safer than alternative heating elements due to their excellent insulation properties.

The superior performance and reliability of ceramic heating elements and ceramic heater elements contribute significantly to the efficiency and longevity of countless devices and systems.

Frequently Asked Questions (FAQs)

Q: What is the difference between a ceramic heating element and a ceramic heater element?

A: The terms are often used interchangeably. However, ceramic heating element is a more general term referring to the resistive heating component, while ceramic heater element might specifically refer to a complete assembly including the element, mounting hardware, and possibly other features.

Q: How long do ceramic heating elements last?

A: The lifespan of a ceramic heating element varies depending on factors such as operating temperature, usage frequency, and environmental conditions. However, they are typically known for their long service life. Proper selection and installation contribute significantly to its longevity.

Q: Can ceramic heating elements be repaired?

A: Generally, no. Damaged ceramic heating elements should be replaced rather than repaired due to safety considerations and the difficulty of repair.

Q: Are ceramic heating elements energy efficient?

A: Yes, ceramic heating elements are highly energy-efficient compared to other heating technologies due to their high conversion rate of electrical energy into heat.

Q: What are the safety considerations when using ceramic heating elements?

A: Always follow the manufacturer's instructions for installation and operation. Ensure proper grounding and avoid overheating.

Conclusion

Ceramic heating elements and ceramic heater elements are essential components in a wide range of applications, providing reliable, efficient, and safe heating solutions. Their versatility, durability, and precision temperature control make them a preferred choice across various industries. We encourage you to explore the possibilities of integrating these advanced components into your projects. Contact our team at DXM to discuss your specific requirements and learn how our high-quality ceramic heating elements can benefit your applications.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Updated on 2nd June 2025

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Logistics

Shipment

1)Small order quantity and small packing:cargo may be arranged by courier;

2)Bulk order and big volume:shipment may be arranged by sea or by air as per customer’s requirements on FOB, C&F,CIF or LCL terms and do prompt shipment which is very important for our customers, so we do this matter seriously and we may arrange our shipment in time due to our rich experiences in this line. We may also accept the shipment on the term of freight prepaid or freight collect.

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

Price and Payment

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

You may also like

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd