PTC Heating Element: How It Works & Benefits

Learn about PTC heating elements and how they work. Discover their self-limiting temperature control, numerous applications, and key advantages. Contact DXM for high-quality PTC thermistors!

- How Does a PTC Heating Element Work? Key Tech Behind Safe, Efficient Heating

- The Science Behind PTC Heating Elements

- How Does a PTC Heating Element Work? A Step-by-Step Explanation

- Applications of PTC Heating Elements: Where They Shine

- Advantages of Using PTC Heating Elements

- Choosing the Right PTC Heating Element

- Frequently Asked Questions (FAQs)

- Q: Can PTC heating elements be used in high-temperature applications?

- Q: How does the lifespan of a PTC heating element compare to other heating elements?

- Q: Are PTC heating elements susceptible to damage from overvoltage?

- Conclusion: The Power of PTC Heating Elements

How Does a PTC Heating Element Work? Key Tech Behind Safe, Efficient Heating

PTC heating element technology powers modern heating systems with safety and efficiency. Knowing how does a PTC heating element work is vital in electronics. A PTC heating element uses a thermistor that increases resistance as temperature rises. This limits current, providing built-in self-regulation. Unlike traditional heaters, it prevents overheating. PTC heaters are widely used in motor starters, HVAC, and consumer electronics. Their reliability, fast response, and compact size offer key design advantages.

The Science Behind PTC Heating Elements

A PTC heating element, or Positive Temperature Coefficient thermistor, is a type of resistor whose resistance significantly increases with rising temperature. This characteristic is the cornerstone of its functionality as a heating element. Unlike traditional resistive heaters, a PTC heating element exhibits a self-limiting temperature characteristic. This means it automatically regulates its temperature, preventing overheating and ensuring consistent performance. The core material of a PTC heating element is typically a ceramic semiconductor, often barium titanate, doped with various elements to fine-tune its properties.

The increase in resistance at elevated temperatures is a consequence of changes in the material's internal structure. As the temperature rises, the material's ability to conduct electricity decreases, thereby limiting the current flow and the heat generated. This intrinsic self-regulation mechanism is a key differentiator of PTC heating elements compared to other heating technologies. The precise characteristics of a PTC heating element, such as its resistance-temperature profile and maximum operating temperature, are determined by the specific material composition and manufacturing process.

How Does a PTC Heating Element Work? A Step-by-Step Explanation

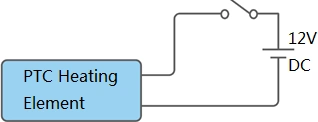

Let's break down the operational mechanism of a PTC heating element in simple terms:

1. Initial State: At room temperature, a PTC heat element exhibits relatively low resistance. When a voltage is applied, a current flows through it.

2. Heating Phase: The current flowing through the PTC element generates heat due to resistive heating (I²R losses). This heat causes the temperature of the element to rise.

3. Resistance Increase: As the temperature of the PTC element increases, its resistance also increases significantly.

4. Self-Limiting Effect: This rise in resistance limits the current flow. Consequently, the rate of heat generation decreases, preventing the PTC heating element from overheating. The element reaches a stable operating temperature. This self-limiting characteristic is crucial for safety and reliability.

5. Stable Operation: The PTC element continues to operate at a relatively constant temperature, determined by the applied voltage and the element's inherent characteristics.

It maintains a stable output of heat, making it an ideal solution for many applications where precise temperature control is crucial. The ability of the PTC heating element to maintain this stable temperature without external control is a significant advantage.

Applications of PTC Heating Elements: Where They Shine

The self-limiting temperature characteristic of PTC heating elements makes them suitable for a wide range of applications, including:

* Automotive Industry: PTC heaters are frequently used in defrosting and defogging systems, seat heaters, and other applications where precise temperature control is required. The reliability and safety offered by PTC heating elements are vital in this demanding environment.

*Consumer Electronics: In many consumer electronics products, PTC heating elements provide efficient and safe heating solutions. Examples include hair dryers, kettles, and various other appliances.

* Industrial Applications: PTC heating elements are also employed in industrial settings for processes that require precise and reliable temperature control.

Advantages of Using PTC Heating Elements

PTC heating elements offer several key advantages compared to other heating technologies:

* Safety: The inherent self-limiting characteristic makes PTC heating elements inherently safe, reducing the risk of overheating and fire hazards.

* Efficiency: PTC heating elements convert electrical energy into heat with high efficiency, resulting in lower energy consumption.

* Simplicity: They are simple to integrate into various systems, requiring minimal control circuitry.

* Long Lifespan: Their robust construction and self-regulating nature contribute to a long and reliable lifespan.

* Precise Temperature Control: Even without complex control circuitry, they provide a reasonable degree of temperature control.

* Small Size and Lightweight: This makes them ideal for integration into portable and compact devices.

Choosing the Right PTC Heating Element

Selecting the appropriate PTC heating element depends on specific application requirements. Factors to consider include the desired power output, operating voltage, and required operating temperature range. Careful consideration of these factors ensures optimal performance and reliability. The manufacturer's specifications should be carefully reviewed to ensure compatibility. Understanding the resistance-temperature profile is also vital.

Frequently Asked Questions (FAQs)

Q: Can PTC heating elements be used in high-temperature applications?

A: While PTC heating elements offer self-limiting protection, their maximum operating temperature is dependent on the specific design and materials. Consult the manufacturer's specifications for high-temperature applications.

Q: How does the lifespan of a PTC heating element compare to other heating elements?

A: Due to their robust construction and self-regulating nature, PTC heating elements typically exhibit a longer lifespan compared to some other heating technologies, minimizing replacement needs.

Q: Are PTC heating elements susceptible to damage from overvoltage?

A: While PTC heating elements are relatively robust, excessive overvoltage can potentially damage them. Proper voltage protection is recommended.

Conclusion: The Power of PTC Heating Elements

PTC heating elements, and understanding how a PTC heating element works, provide a safe, efficient, and reliable heating solution for a diverse range of applications. Their self-limiting temperature characteristic is a significant advantage, promoting safety and simplifying system design. We encourage you to explore the full potential of PTC heating elements in your projects. Contact DXM today to learn more about our high-quality PTC heating elements and discover how we can help you integrate them into your next project.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

Price and Payment

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

You may also like

PTC Heater Element : Key Features, Applications, and Benefits

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd