Element PTC: Pioneering Thermistor Technology Across Industries

DXM’s Element PTC thermistors lead innovation across industries, offering reliable temperature sensing and protection solutions. Explore our advanced thermistor technology designed for efficiency and durability in diverse applications. Trust DXM for cutting-edge Element PTC thermistors.

- Understanding PTC and NTC Thermistor Element

- PTC Element: The Game-Changers

- NTC Thermistors: Precision in Temperature Sensing

- Element PTC's Thermistor Solutions: Transforming Industries

- 1. Thermistor Applications in the Lighting Industry

- 2. Element PTC Use in Consumer Electronics

- 3. Thermistor Protection in Telecommunications

- 4. Element PTC Innovations in the Automotive Industry

- 5. Thermistors in Home Appliances

- 6. Industrial Applications of Thermistors

- Beyond Thermistors: Element PTC's Expanding Portfolio

- Zinc Oxide Varistors

- Ceramic Capacitors

- PTC Heaters

- The Element PTC Advantage

- 1. Cutting-edge Thermistor Research and Development

- 2. Element PTC Customization Capabilities

- 3. Thermistors Quality Assurance

- 4. Global Element PTC Support Network

- 5. Sustainability Focus in Thermistor Manufacturing

- Looking Ahead: The Future of Thermistor Technology

- 1. Thermistor Miniaturization

- 2. Enhanced Temperature Ranges in Thermistors

- 3. Thermistor Integration with IoT and Smart Systems

- 4. Improved Energy Harvesting Through Thermistors

- Conclusion of Element PTC

- Frequently Asked Questions About Element PTC Thermistors

- Q: What is the main difference between PTC and NTC Element?

- Q: In which industries are Element PTC's thermistors most commonly used?

- Q: Can PTC Elements provide custom thermistor solutions?

- Q: What are some emerging trends in thermistor technology?

- Q: How do Element PTC's thermistors contribute to energy efficiency?

Element PTC is leading the advancement in thermistor technology, providing innovative solutions for various industries. Our PTC thermistors ensure reliable thermal management and effective circuit protection in electronics, automotive, and beyond. With a focus on precision and durability, Element PTC delivers superior thermistor performance, setting new standards in the industry. Our cutting-edge thermistors optimize device efficiency and prevent overheating, making them essential components for modern applications. Explore how Element PTC's thermistors are redefining safety and functionality across sectors.

Understanding PTC and NTC Thermistor Element

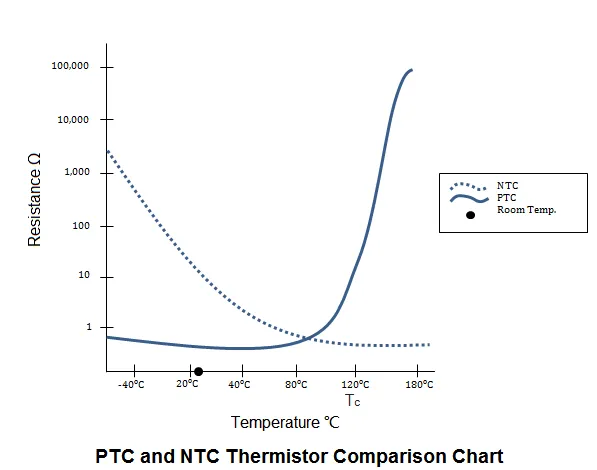

Before delving into the myriad applications of Element PTC's technology, let's briefly explore the two main types of thermistor Elements: Positive Temperature Coefficient (PTC) and Negative Temperature Coefficient (NTC) thermistors.

PTC Element: The Game-Changers

PTC Elements, a specialty of Element PTC, exhibit increased resistance as temperature rises. This unique property makes them ideal for various applications, including:

- Overcurrent protection

- Self-regulating heating elements

- Motor starting

- Degaussing in CRT displays

NTC Thermistors: Precision in Temperature Sensing

NTC thermistors, on the other hand, decrease in resistance as temperature increases. They excel in:

- Temperature Recompense in electronic circuits

- Limiting surge current

- Temperature measurement and control

Element PTC's Thermistor Solutions: Transforming Industries

Element PTC's innovative thermistor solutions are making waves across numerous sectors. Let's explore some key industries benefiting from this groundbreaking technology.

1. Thermistor Applications in the Lighting Industry

In the lighting sector, Element PTC's thermistors play a crucial role in:

- Delay start mechanisms for fluorescent lamp electronic ballasts

- Intelligent preheat start systems in energy-saving lamps

These applications ensure smoother starts and extended lamp life, contributing to energy efficiency and sustainability efforts.

2. Element PTC Use in Consumer Electronics

Element PTC's thermistors find extensive use in consumer electronics, particularly in:

- Degaussing circuits for color TVs and monitors

- Overcurrent and overload protection in power supplies, chargers, and computer peripherals

By incorporating Element PTC's technology, manufacturers can enhance the safety and reliability of their products, meeting consumer demands for durable and high-performance devices.

3. Thermistor Protection in Telecommunications

In the fast-paced world of telecommunications, Element PTC's thermistors provide crucial protection in:

- Central office communication equipment

- PBXs and remote XDSL exchanges

- Outdoor telephone installations

These applications ensure the integrity and reliability of communication networks, even in challenging environmental conditions.

4. Element PTC Innovations in the Automotive Industry

Element PTC's innovations are driving progress in the automotive sector, with applications including:

- Motor starters for efficient engine ignition

- Temperature control in air conditioning systems

- Overcurrent protection in various automotive electronics

As vehicles become increasingly electrified and connected, Element PTC's thermistor technology plays a vital role in ensuring safety, reliability, and performance.

5. Thermistors in Home Appliances

Thermistors are integral to many household appliances, including:

- Refrigerators and deep freezers

- Water heaters and coffee makers

- Washing machines and dryers

- Air conditioners and heat pumps

By incorporating Element PTC's technology, appliance manufacturers can offer products with improved energy efficiency, safety features, and precise temperature control.

6. Industrial Applications of Thermistors

In industrial settings, Element PTC's thermistors find use in:

- Motor protection circuits

- Industrial heating and drying equipment

- Temperature sensors for process control

These applications contribute to improved safety, efficiency, and reliability in various industrial processes.

Beyond Thermistors: Element PTC's Expanding Portfolio

While thermistors remain a cornerstone of Element PTC's offerings, the company has expanded its product line to include other critical components:

Zinc Oxide Varistors

Element PTC's zinc oxide varistors provide surge protection in various applications, including:

- Telecommunications equipment

- Power distribution systems

- Consumer electronics

These components safeguard sensitive electronics from voltage spikes and transients, ensuring longer device lifespans and improved reliability.

Ceramic Capacitors

Element PTC offers a range of ceramic capacitors, including:

- AC ceramic disc capacitors

- Safety-standard recognized ceramic capacitors

- High-voltage ceramic disc capacitors

These components find applications in radio communications, electronic products, and various types of electronic equipment.

PTC Heaters

Element PTC's PTC heaters are revolutionizing heating solutions in applications such as:

- Automotive seat heaters

- Defrosting systems

- Small appliances like hair dryers and space heaters

These self-regulating heating elements offer improved safety and energy efficiency compared to traditional heating technologies.

The Element PTC Advantage

What sets Element PTC apart in the competitive landscape of thermistor and electronic component manufacturing?

1. Cutting-edge Thermistor Research and Development

Element PTC invests heavily in R&D, constantly pushing the boundaries of thermistor technology. This commitment to innovation ensures that customers always have access to the most advanced solutions available.

2. Element PTC Customization Capabilities

Recognizing that one size doesn't fit all, Element PTC offers customization services, allowing clients to obtain thermistor Elements and other components tailored to their specific applications and requirements.

3. Thermistors Quality Assurance

Element PTC maintains rigorous quality control processes, ensuring that every component meets or exceeds industry standards. This commitment to quality translates to improved reliability and performance in end-user applications.

4. Global Element PTC Support Network

With a worldwide presence, Element PTC provides localized support and rapid response times, ensuring that clients receive the assistance they need, when they need it.

5. Sustainability Focus in Thermistor Manufacturing

Element PTC is committed to sustainable manufacturing practices, developing energy-efficient components that contribute to reduced power consumption in various applications.

Looking Ahead: The Future of Thermistor Technology

As we look to the future, Element PTC continues to drive innovation in thermistor technology. Some exciting areas of development include:

1. Thermistor Miniaturization

As devices become smaller and more compact, Element PTC is working on developing increasingly miniaturized thermistor Elements without compromising performance.

2. Enhanced Temperature Ranges in Thermistors

Research is underway to expand the operational temperature ranges of thermistors, opening up new possibilities in extreme environment applications.

3. Thermistor Integration with IoT and Smart Systems

Element PTC is exploring ways to integrate thermistor technology with IoT platforms, enabling advanced temperature monitoring and control in smart homes and industrial settings.

4. Improved Energy Harvesting Through Thermistors

Ongoing research aims to leverage the thermoelectric properties of certain materials to develop more efficient energy harvesting solutions.

Conclusion of Element PTC

Element PTC stands at the forefront of thermistor technology, driving innovation across various industries. From consumer electronics to industrial applications, the company's cutting-edge solutions are reshaping how we approach thermal management, circuit protection, and energy efficiency.

As technology continues to evolve, PTC Elements remain committed to pushing the boundaries of what's possible, developing new and improved thermistor solutions that meet the challenges of tomorrow. Whether you're a manufacturer looking to enhance your products or an engineer seeking the perfect thermal management solution, Element PTC offers the expertise, quality, and innovation to meet your needs.

Explore the world of Element PTC and discover how our advanced thermistor technology can revolutionize your applications. Contact us today to learn more about our products and customization options.

Frequently Asked Questions About Element PTC Thermistors

Q: What is the main difference between PTC and NTC Element?

A: PTC (Positive Temperature Coefficient) Elements increase in resistance as temperature rises, while NTC (Negative Temperature Coefficient) Elements decrease in resistance as temperature increases. This fundamental difference makes them suitable for different applications.

Q: In which industries are Element PTC's thermistors most commonly used?

A: Element PTC's thermistors find extensive use in various industries, including lighting, consumer electronics, telecommunications, automotive, home appliances, and industrial applications.

Q: Can PTC Elements provide custom thermistor solutions?

A: Yes, PTC Elements offer customization services to meet specific client requirements. They can tailor thermistors and other components to suit particular applications and specifications.

Q: What are some emerging trends in thermistor technology?

A: Some emerging trends include miniaturization for use in smaller devices, development of thermistors with expanded temperature ranges, integration with IoT and smart systems, and improved energy harvesting capabilities.

Q: How do Element PTC's thermistors contribute to energy efficiency?

A: Element PTC's thermistors contribute to energy efficiency in various ways, such as enabling more precise temperature control in appliances, providing efficient motor starting mechanisms, and offering self-regulating heating solutions that consume less power.

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Logistics

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Price and Payment

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

You may also like

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd