Essential Guidelines for PTC Switch Usage and Maintenance

Learn about essential guidelines for PTC Switch usage and maintenance with DXM. Learn how to optimize your ptc thermal switch and PTC resistors for improved safety and performance. Follow expert tips to extend lifespan and ensure reliable operation in all applications.

- Key Precautions for PTC Switch Operation

- 1. Operating Within PTC Switch Specifications

- 2. Environmental Considerations for PTC Resistors

- Proper Handling and Maintenance of PTC Resistors

- 1. Cleaning Techniques for PTC Switch

- 2. Soldering Best Practices

- 3. Coating and Potting Considerations

- 4. Optimal Storage Conditions

- Advanced Applications of PTC Switch

- 1. Overcurrent Protection

- 2. Temperature Sensing and Control

- 3. Self-Regulating Heating Elements

- Troubleshooting Common PTC Switch Issues

- 1. Resistance Drift

- 2. Slow Response Time

- 3. Intermittent Operation

- Future Trends in PTC Switch Technology

- 1. Miniaturization

- 2. Enhanced Temperature Stability

- 3. Integration with IoT Devices

- Frequently Asked Questions about PTC Switch

PTC Switch is critical component of PTC Resistors in various electronic applications. Understanding their proper use and maintenance is crucial for optimal performance and longevity. This guide delves into the essential aspects of handling PTC thermal switch, from usage precautions to storage recommendations.

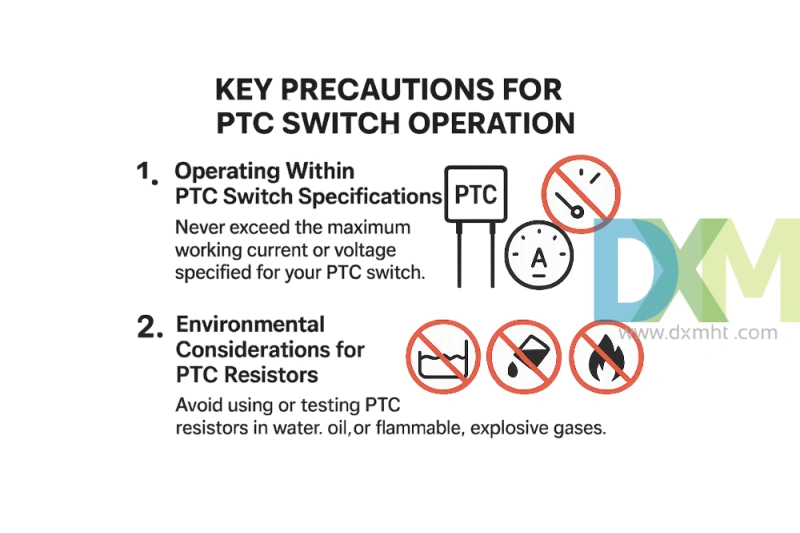

Key Precautions for PTC Switch Operation

When working with PTC Switches, it's vital to adhere to specific guidelines to prevent short circuits, burning accidents, or component failure. Here are the primary considerations:

1. Operating Within PTC Switch Specifications

Never exceed the maximum working current or voltage specified for your PTC Switch. Operating beyond these limits can lead to device failure or safety hazards.

2. Environmental Considerations for PTC Resistors

Avoid using or testing PTC Resistors in water, oil, or flammable explosive gases. These environments can compromise the integrity and functionality of the component.

Proper Handling and Maintenance of PTC Resistors

To ensure the longevity and reliability of your PTC thermal switch, follow these guidelines for cleaning, soldering, and storage:

1. Cleaning Techniques for PTC Switch

Use appropriate cleaning agents such as Freon, trichloroethane, or tetrachloroethylene mild detergent for PTC Resistors. Ultrasonic cleaning is also effective, but be cautious as some detergents may affect the thermistor's performance.

2. Soldering Best Practices

Proper soldering techniques are crucial to prevent damage from excessive heating. Adhere to these specifications:

Remember, improper soldering conditions can alter the resistance value of your PTC thermal switch.

3. Coating and Potting Considerations

When applying coatings or potting materials to PTC Switches, be mindful of mechanical stress caused by thermal expansion. Use chemically neutral materials and avoid exceeding the PTC Thermistor's maximum temperature during the curing process.

4. Optimal Storage Conditions

While PTC Resistors have no strict time limits for storage, maintaining proper conditions is crucial:

- Store in a non-corrosive atmosphere

- Monitor humidity and temperature

- Use appropriate container materials

- Keep components in original packaging when possible

Proper storage preserves the solderability and overall performance of PTC Switches.

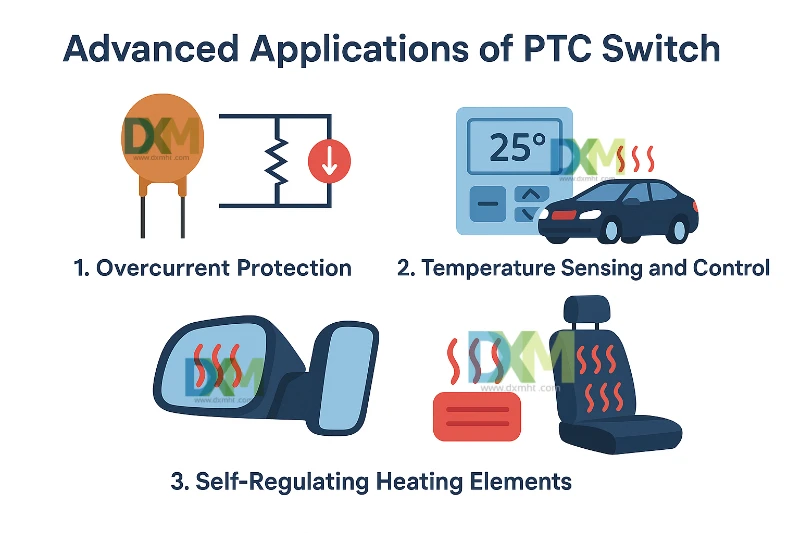

Advanced Applications of PTC Switch

PTC Switches find applications in various industries due to their unique properties. Some advanced uses include:

1. Overcurrent Protection

PTC Resistors excel in protecting circuits from overcurrent situations. Their ability to rapidly increase resistance in response to temperature rise makes them ideal for this purpose.

2. Temperature Sensing and Control

In HVAC systems and automotive applications, PTC thermal switches play a crucial role in maintaining optimal temperatures and preventing overheating.

3. Self-Regulating Heating Elements

PTC Switches are used in self-regulating heating applications, such as automotive mirrors and seats, providing efficient and safe heating solutions.

Troubleshooting Common PTC Switch Issues

Even with proper care, PTC Resistors may encounter issues. Here are some common problems and solutions:

1. Resistance Drift

If you notice unexpected changes in resistance, check for exposure to extreme temperatures or mechanical stress. Recalibration may be necessary.

2. Slow Response Time

A decrease in response time could indicate contamination or aging. Clean the PTC thermal switch carefully and consider replacement if issues persist.

3. Intermittent Operation

Check for loose connections or solder joints. Ensure the PTC thermal switch is properly seated and free from mechanical stress.

Future Trends in PTC Switch Technology

The field of PTC Resistors continues to evolve. Here are some emerging trends:

1. Miniaturization

As electronic devices become smaller, there's a growing demand for more compact PTC Switches without compromising performance.

2. Enhanced Temperature Stability

Research is ongoing to develop PTC thermal switches with improved stability across wider temperature ranges.

3. Integration with IoT Devices

PTC Resistors are being integrated into IoT devices for smart temperature management and predictive maintenance applications.

Frequently Asked Questions about PTC Switch

Q: What is the typical lifespan of a PTC Switches?

A: The lifespan of a PTC Switches can vary depending on usage conditions, but with proper handling and operation within specified parameters, they can last for many years. Regular inspection and maintenance can further extend their operational life.

Q: Can PTC Resistors be used in high-voltage applications?

A: While PTC Switches are versatile, their use in high-voltage applications depends on their specific design and ratings. Always consult the manufacturer's specifications and consider using specially designed high-voltage PTC Resistors for such applications.

Q: How do environmental factors affect PTC Switch performance?

A: Environmental factors like humidity, temperature extremes, and chemical exposure can significantly impact PTC switch performance. It's crucial to choose PTC Resistors rated for your specific environmental conditions and to provide adequate protection when necessary.

Q: Are there any alternatives to PTC Switches for similar applications?

A: While PTC Switches are unique in their self-regulating properties, alternatives for specific applications might include NTC thermistors, bimetallic switches, or solid-state relays. The choice depends on the specific requirements of your application.

For more details on advanced PTC Switch applications and technologies, explore our comprehensive range of PTC thermal switches and PTC Resistors. Stay updated on the latest innovations to enhance performance and reliability in your electronic devices. Discover solutions tailored to your needs.

Author: Ivan Huang

© 2024 DXM Blog. All rights reserved.

Updated on 4th July 2025

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Price and Payment

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

Logistics

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

You may also like

PTC Resistors MZ71 Degauss Thermistor for TV monitor Degaussing

Thermistor PTC Resistors TV degausser - High Stability MZ72

Thermistor PTC Device for Meter instrument overvoltage protection

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd