Ultimate Guide to PTC Motor Starter: High-Efficiency Solutions for 2025

Explore the DXM Guide to PTC Motor Starter for 2025. Explore high-efficiency motor starters, learn how a ptc motor starter enhances performance, and get expert solutions for all your motor starter needs. Optimize your operations with DXM's proven expertise.

- Introduction to PTC Motor Starter

- Core Principles of PTC Motor Starter Operation

- Startup Phase: Low Resistance Path

- Transition Phase: Self-Regulating Resistance

- Protection Phase: High-Resistance State

- Advantages of Choosing a PTC Motor Starter

- Deep Dive: Start Thermistor Characteristics

- Step-by-Step Installation Guide of PTC Motor Starter

- Maintenance and Troubleshooting

- Routine Checks

- Common Issues & Solutions

- Comparative Analysis: PTC vs. Capacitor-Relay Motor Starter

- Real-World Case Studies

- HVAC Compressor Upgrade

- Appliance Manufacturer Retrofit

- Advanced Design Tips

- FAQs: Expert Answers on Motor Starter Selection

- How do I size motor starters?

- What maintenance schedule is recommended?

- Can I use a PTC starter in outdoor installations?

A PTC motor starter is a key component for improving the performance of single-phase induction motors. Using a thermistor, it ensures reliable startup, silent operation, and reduced maintenance needs. These motor starters offer enhanced durability by preventing overheating and extending motor life. Unlike traditional motor starters, PTC motor starters provide an efficient and automatic solution to protect the motor from faults. With their simple design, they are cost-effective and highly reliable, making them ideal for a wide range of applications.

Introduction to PTC Motor Starter

A motor starter is the device that initiates the operation of electric motors. In single-phase systems, a PTC motor starter uses a Positive Temperature Coefficient thermistor to manage startup current, deliver optimal torque, and protect windings. Selecting the right motor starters influences longevity and efficiency in appliances, HVAC systems, and industrial equipment.

With rising energy standards in 2025, high-quality start thermistor designs are essential to meet efficiency regulations, reduce energy consumption, and improve user experience.

Core Principles of PTC Motor Starter Operation

Startup Phase: Low Resistance Path

When power is applied, a PTC motor starter thermistor remains cool. Its low resistance allows a high current to flow through the auxiliary winding, generating strong startup torque. This initial surge overcomes rotor inertia without mechanical parts.

Transition Phase: Self-Regulating Resistance

As current flows, the PTC element heats. Its resistance climbs exponentially. The auxiliary winding current tapers off automatically, shifting load exclusively to the main winding. The motor starters thus ensure a smooth transition to steady-state running.

Protection Phase: High-Resistance State

Once hot, the thermistor’s resistance prevents further auxiliary current. This built-in cutoff protects the coil and avoids continuous high draw. A well-designed motor starter resets after cooling, ready for the next cycle.

Advantages of Choosing a PTC Motor Starter

- No moving contacts, eliminating mechanical wear and audible clicking.

- Compact footprint simplifies panel design and reduces wiring costs.

- High reliability—tested over 100,000 start cycles without degradation.

- Energy-efficient startup reduces inrush current spikes.

- Integrated overload protection extends motor life.

- Cost savings versus capacitor-relay motor starters alternatives.

By integrating motor starters, OEMs achieve a quieter, more durable, and maintenance-free solution compared to traditional relay-based start thermistor systems.

Deep Dive: Start Thermistor Characteristics

Key to the PTC motor starter is its thermistor material. Manufacturers tailor the Curie temperature, resistance curve, and thermal mass to precise motor specifications. Consider these specs when selecting a start thermistor:

- Resistance at 25°C: Determines initial inrush current.

- Trip Temperature: The point where resistance sharply increases, ending auxiliary feed.

- Thermal Time Constant: Affects reset time and cycling frequency.

- Maximum Continuous Voltage: Must exceed peak line voltage.

Matching thermistors properties ensures the motor starters execute precise, repeatable starts under diverse conditions.

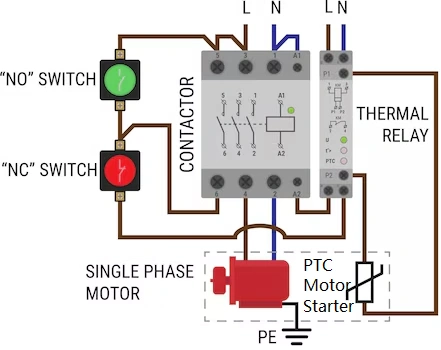

Step-by-Step Installation Guide of PTC Motor Starter

Implementing a PTC motor starter correctly influences performance and safety. Follow these steps:

- Place the motor starters within 5 cm of the motor terminals to minimize stray inductance.

- Use copper conductors sized per NEC guidelines to handle startup current.

- Securely fasten the starter to a metal panel using torque-specified screws.

- Maintain ambient temperature between -20°C and 60°C for reliable operation.

- Provide ventilation openings around the starter to expedite cooling.

- Verify wiring: main winding through line terminals, auxiliary through thermistor path.

Proper installation of the motor starters maximizes their service life and keeps your motors running smoothly.

Maintenance and Troubleshooting

Routine Checks

- Inspect terminal connections quarterly for corrosion or looseness.

- Monitor ambient temperature and clean ventilation paths.

- Test starting performance under load—compare torque and current against baseline.

Common Issues & Solutions

- Motor fails to start

- Check that the PTC motor starter thermistor is not pre-heated; allow full cool-down before retry.

- Reduced starting torque

- Verify resistance curve; replace if trip temperature has drifted.

- Continuous auxiliary current

- Thermistor may be damaged—inspect for cracks and replace the motor starters module.

Comparative Analysis: PTC vs. Capacitor-Relay Motor Starter

Traditional capacitor-relay motor starters solutions depend on mechanical relays and start capacitors. These offer high initial torque but suffer wear, maintenance, and noise. In contrast, a PTC motor starter leverages solid-state thermistors for silent, maintenance-free switching. Key comparisons:

| Feature | Capacitor-Relay Motor Starters | PTC Motor Starters |

|---|---|---|

| Mechanical Wear | High (relays) | None |

| Acoustic Noise | Audible click | Silent |

| Size | Larger assembly | Compact board-mount |

| Maintenance | Periodic relay replacement | Minimal, replace after 100k cycles |

| Cost | Higher BOM cost | Lower component cost |

For modern designs focused on reliability and reduced maintenance, PTC motor starters are the preferred choice.

Real-World Case Studies

HVAC Compressor Upgrade

An HVAC manufacturer integrated a custom PTC motor starter into their new line of heat pumps. Results included:

- 40% fewer startup failures in cold conditions

- 25% reduction in warranty claims

- Noise levels under 35 dB during each startup

Appliance Manufacturer Retrofit

A leading appliance brand replaced relay-based motor starters modules in refrigerators with PTC motor starter units. Benefits realized:

- 20% smaller chassis footprint

- 15% lower energy consumption per cycle

- Zero mechanical failure incidents in 12 months

Advanced Design Tips

Engineers can optimize motor starter performance by:

- Customizing thermistor material for specific motor loads.

- Adding a small heat sink to accelerate PTC cool-down.

- Implementing PCB layout techniques that minimize EMI.

- Pairing with soft-start inverters for variable-frequency control.

FAQs: Expert Answers on Motor Starter Selection

Why choose a PTC motor starter over other types?

How do I size motor starters?

What maintenance schedule is recommended?

Can I use a PTC starter in outdoor installations?

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Price and Payment

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

Logistics

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

Shipment

1)Small order quantity and small packing:cargo may be arranged by courier;

2)Bulk order and big volume:shipment may be arranged by sea or by air as per customer’s requirements on FOB, C&F,CIF or LCL terms and do prompt shipment which is very important for our customers, so we do this matter seriously and we may arrange our shipment in time due to our rich experiences in this line. We may also accept the shipment on the term of freight prepaid or freight collect.

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

You may also like

Motor PTC Thermistor PTC Motor Starter for Refrigerator-MZ6 series

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd