Best Practices for Handling and Storing PTC Devices

Discover DXM’s expert guide on Best Practices for Handling and Storing PTC Devices. Learn essential tips to maintain the performance and longevity of PTC thermistors, ensuring reliable operation in your applications. Optimize device care with DXM’s trusted solutions.

Introduction of Essential Practices for Handling and Storing PTC Devices

For optimal performance and longevity, proper handling and storage of PTC Devices, especially including PTC Thermistors and ptc ceramic elements, are essential. Adhering to these guidelines ensures that your PTC Devices function reliably over time, minimizing potential issues related to improper care.

1. Cleaning PTC Devices

When cleaning PTC Thermistors, it's important to use suitable cleaning agents. Approved cleaners include Freon, trichloroethane, or tetrachloroethylene. Ultrasonic cleaning can also be used; however, be cautious as some detergents may damage the PTC Thermistors 's performance. Always ensure that the cleaning method does not negatively affect the device’s functionality.

2. Welding Requirements of PTC Thermistors

| Welding Method | Temperature (Max) | Time (Max) | Distance from PTC Thermistor (Min) |

|---|---|---|---|

| Dip Soldering of ptc ceramic elements | 260°C | 10 seconds | 6 mm |

| Iron Welding | 360°C | 5 seconds | 6 mm |

During welding, it is critical to avoid excessive heat exposure, which can alter the resistance values of the PTC Thermistors. Maintaining the correct distance from the welding point and adhering to the recommended temperature and time limits will help preserve the integrity of the PTC Thermistors.

3. Coating and Potting Guidelines of ptc ceramic elements

Coating and potting are common practices in PTC Devices to protect components, but they require careful execution. Mechanical stress during the solidification process can lead to damage due to differences in thermal expansion. It’s vital to use chemically neutral potting materials and to keep the curing temperatures within the recommended range. Exceeding the upper temperature limit can reduce resistance and impair the electrical properties of the PTC Thermistors, potentially leading to overheating and device failure.

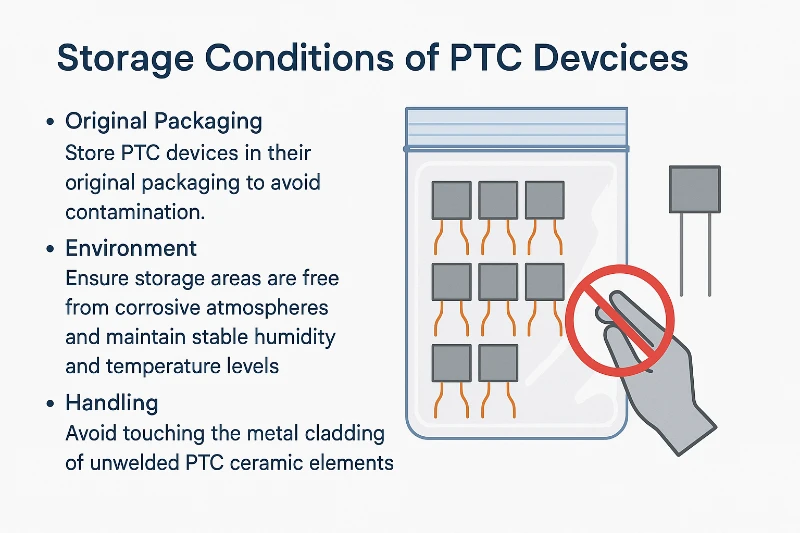

4. Storage Conditions of PTC Devices

Proper storage of PTC Thermistors is crucial to maintain their quality and functionality:

- Original Packaging: Store PTC Devices in their original packaging to avoid contamination.

- Environment: Ensure storage areas are free from corrosive atmospheres and maintain stable humidity and temperature levels.

- Handling: Avoid touching the metal cladding of unwelded ptc ceramic elements to prevent degradation in solderability.

- Longevity: ptc ceramic elements can be preserved long-term if stored under ideal conditions. However, exposure to high humidity or temperatures may affect solderability and other performance characteristics.

-

Following these best practices for handling and storage ensures that PTC Devices, remain in peak condition, delivering reliable performance over their lifespan. These guidelines not only protect the devices but also enhance your product's reliability and market competitiveness.

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Updated on 14th June 2025

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Logistics

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

Price and Payment

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

You may also like

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Termistor PTC Thermistors MZ21 Series: Reliable Protection for Telecom Main Distribution Frame

PTC Electric Thermistors for telecom apparatus circuit protection (MZ23 series)

PTC Electronics MZ31 Series MZ8 Type: Reliable Overcurrent and Overload Protection Solutions

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd