Thermistor NTC Applications for Effective Inrush Current Limiting

Option 1 (Focus on Problem/Solution): DXM's Thermistor NTC solutions offer effective inrush current limiting. Discover how our NTC thermistors protect sensitive circuits, ensuring reliable performance. Explore NTC thermistor applications today!

Option 2 (Benefit-Oriented): Boost circuit protection with DXM's NTC Thermistors! Learn about the advantages of NTC thermistors for inrush current limiting. Browse our NTC thermistors range for optimized performance.

Option 3 (Direct & Concise): Thermistor NTC from DXM for superior inrush current limiting. Find the right NTC thermistor for your application.

Explore our selection!

- Thermistor NTC Applications in Inrush Current Limiting

- Introduction

- Applications :

- 1. Inrush Current Limiting in Switch Mode Power Supplies (SMPS)

- 2. Inrush Current Limiting in AC-DC Power Modules

- 3. Inrush Current Limiting in DC-DC Converters

- 4. Inrush Current Limiting in Industrial Inverters

- Conclusion

Thermistor NTC Applications in Inrush Current Limiting

Introduction

NTC (Negative Temperature Coefficient) thermistors are crucial components in many electronic devices, known for their ability to effectively manage inrush current. This article will explore various applications of thermistor ntc in inrush current limiting, particularly in Switch Mode Power Supplies (SMPS), AC-DC power modules, DC-DC converters, and industrial inverters.

Applications :

1. Inrush Current Limiting in Switch Mode Power Supplies (SMPS)

Switch Mode Power Supplies (SMPS) are popular due to their compact size, lightweight design, and high performance. When an SMPS is powered on, it experiences a high peak inrush current as the filter capacitor charges. This inrush current can reduce the lifespan of the capacitor, damage the power switch contacts, or destroy rectifying diodes, necessitating effective countermeasures.

NTC thermistors are widely used to limit the inrush current in SMPS, offering a low-cost and straightforward solution. Connecting an NTC thermistor even after the rectifier circuit yields similar benefits.

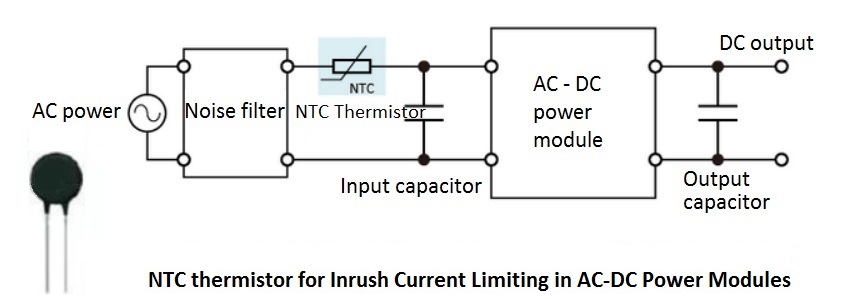

2. Inrush Current Limiting in AC-DC Power Modules

Power modules, integrating various power circuits and peripheral components, are termed built-in power supplies. AC-DC power modules consist of AC-DC rectifier circuits, DC-DC converters, and minimal external components, forming a space-saving optimized power system. An NTC thermistor effectively limits the inrush current applied to the input and output capacitors when powering on.

Figure : NTC thermistor for Inrush Current Limiting in AC-DC Power Modules

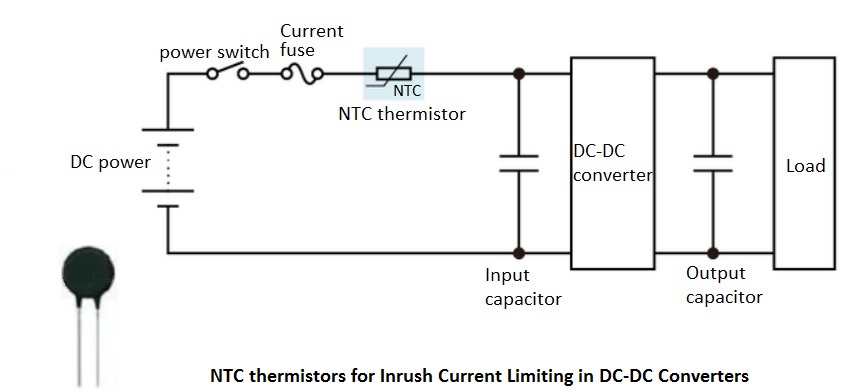

3. Inrush Current Limiting in DC-DC Converters

In DC power circuits like DC-DC converters, NTC thermistors serve as power thermistors to limit inrush current during the initial power-on phase when input and output capacitors are charging. The resistance of the NTC thermistor drops significantly after power-on, reducing power loss compared to using a fixed resistor.

Figure : Negative Temperature Coefficient NTC Thermistor for Inrush Current Limiting in DC-DC Converters

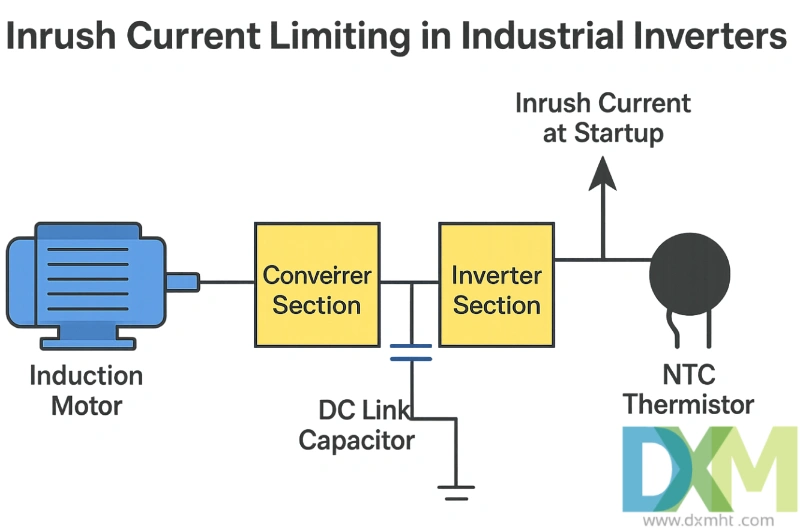

4. Inrush Current Limiting in Industrial Inverters

Induction motors, commonly used in factories, large facilities, and office buildings, drive fans, pumps, air conditioners, and other equipment. These motors, while simple and stable, have speeds dependent on frequency and require inverters for speed control. Motors with inverters, known as variable speed drives (VSDs), significantly reduce power consumption.

An inverter system comprises a converter section, an inverter section, and a DC link capacitor (filter capacitor) after the converter. At startup, the device charges, and an inrush current several times larger than the steady-state current fills the DC link capacitor. This inrush current can adversely affect the lifespan of the DC capacitor or damage semiconductor devices. To prevent this, an NTC thermistor (power thermistor) is connected.

Conclusion

NTC thermistors are essential in managing inrush current across various applications, including SMPS, AC-DC power modules, DC-DC converters, and industrial inverters. Their ability to effectively limit inrush current ensures the longevity and reliability of electronic components, making them indispensable in modern electronic systems. By integrating NTC thermistors, engineers can enhance the performance and safety of power systems.

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Updated on 9th June 2025

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Shipment

1)Small order quantity and small packing:cargo may be arranged by courier;

2)Bulk order and big volume:shipment may be arranged by sea or by air as per customer’s requirements on FOB, C&F,CIF or LCL terms and do prompt shipment which is very important for our customers, so we do this matter seriously and we may arrange our shipment in time due to our rich experiences in this line. We may also accept the shipment on the term of freight prepaid or freight collect.

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

Price and Payment

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Customized Services

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

You may also like

NTC Thermistor Inrush Current limiter MF72

Negative Temperature Coefficient Thermistor for temperature compensation (MF11 series)

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd