What is a PTC Heater? Understanding PTC Heaters for Optimal Heating Solutions

Discover the advanced technology of PTC heater with DXM's expert insights. Perfect for energy-efficient and safe heating, PTC heaters self-regulate temperature, ensuring optimal performance. Learn how PTC heaters redefine heating solutions, providing reliability and sustainability. Explore DXM's leadership in PTC heater innovations for superior comfort in various applications.

- Introduction to PTC Heater Technology

- Understanding PTC Heaters: How Do They Work?

- Technical Details: The Science Behind PTC Heaters

- Benefits of PTC Heaters

- 1. Energy Efficiency of PTC Heaters

- 2. PTC heater for Safety

- 3. Durability and Reliability

- 4. Versatility

- Applications of PTC Heaters

- Choosing the Right PTC Heater for Your Needs

- Factors to Consider

- Why Are PTC Heaters Considered Energy Efficient?

- Energy Efficiency in Practice

- Safety Features of PTC Heaters

- Durability and Low Maintenance of PTC Heaters

- Long-Term Reliability of PTC Heaters

- Versatility of PTC Heaters in Different Industries

- Automotive Applications

- PTC Heater used for Household Appliances

- Industrial Equipment

- Choosing the Right PTC Heater: Practical Tips

- FAQs about PTC Heater

- Conclusion: The Future of PTC Heater is Here

In today's world of advanced heating, PTC heaters excel in efficiency and safety. But what is a PTC heater? It uses special materials for self-regulating temperature control. This ensures both optimal performance and energy efficiency. Understanding what is a PTC heater and its benefits is essential for those seeking reliable, energy-efficient heating solutions.

PTC heaters provide consistent heat output and automatically maintain the right temperature. Their Positive Temperature Coefficient materials enhance safety by preventing overheating.Key benefits include energy-saving, self-regulation, and low maintenance—making PTC heater ideal for many industries needing safe and efficient heating.

Introduction to PTC Heater Technology

What is a PTC heater? In evolving industries, reliable heating is essential. PTC heaters deliver energy efficiency and advanced safety. Their minimal maintenance and modern approach make them preferable to traditional heaters. The importance of PTC heater cannot be overstated. It regulates temperature effectively and is becoming popular for diverse applications needing consistent performance.

Understanding PTC Heaters: How Do They Work?

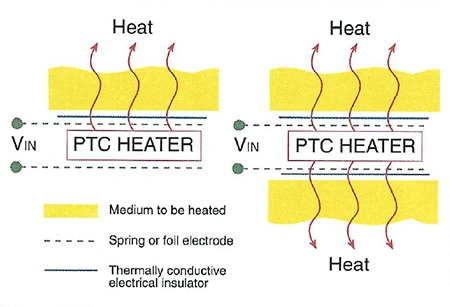

What is a PTC heater? PTC heaters use materials with a positive temperature coefficient of resistance. As temperature rises, so does the electrical resistance. Unlike traditional heaters, PTC heaters avoid overheating. They self-regulate to provide safe and efficient heating. This technology offers consistent and controlled heat output. It eliminates the need for complex external monitoring systems. PTC heater delivers reliability and energy efficiency, setting it apart in heating solutions.

Technical Details: The Science Behind PTC Heaters

The core element of a PTC heater is usually a ceramic component. When electrical current flows through it, the ceramic's resistance rises as the temperature increases. This self-limiting feature ensures that the heater maintains a consistent, safe temperature without requiring complex sensors or additional control mechanisms. The Positive Temperature Coefficient behavior of the ceramic means that it can adjust the heating output dynamically, making PTC heaters incredibly efficient for many heating applications.

Benefits of PTC Heaters

1. Energy Efficiency of PTC Heaters

PTC heaters adjust their power consumption according to the environment. As they reach their optimal temperature, they draw less power, which means lower energy bills. This energy-saving feature makes them a cost-effective choice for both domestic and industrial use. The self-regulating feature of a PTC heater means that it uses power only when necessary, avoiding the excessive energy consumption often seen with traditional resistive heater.

2. PTC heater for Safety

The inherent self-regulating characteristic of PTC heater minimizes the risk of overheating and potential fire hazards. This is especially critical in applications where safety is a primary concern, such as medical devices or household appliances. Unlike conventional heaters that can easily reach dangerous temperatures, PTC heaters ensure that temperatures remain within safe limits, providing peace of mind for users.

3. Durability and Reliability

Since PTC heaters do not rely on moving parts or mechanical thermostats, they are less prone to wear and tear. This leads to a longer operational life and reduced maintenance requirements, which is beneficial for continuous-use applications. The reliability of PTC heater makes it ideal for industries that require dependable heating solutions that can operate for extended periods without interruption.

4. Versatility

PTC heaters are highly adaptable, making them suitable for a variety of settings, including automotive, medical, household, and industrial applications. They offer precise temperature control, which is often needed in sensitive environments. For instance, in automotive applications, PTC heater is used for defogging windshields and heating car seats, providing comfort and safety for drivers and passengers alike.

Applications of PTC Heaters

PTC heaters find use in a wide array of industries. Here are some of the common applications:

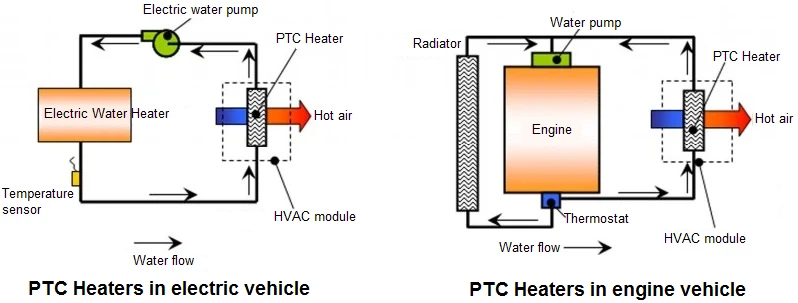

- Automotive Industry: Heating seats, defogging windows, and temperature control. PTC heaters in the automotive sector are widely used due to their efficiency and safety. For example, heated car seats are equipped with PTC heating elements that provide rapid warmth and automatically adjust to maintain a comfortable temperature.

- Medical Equipment: Maintaining stable temperatures in incubators and respiratory devices. In medical environments, safety and precision are critical. PTC heater is used in incubators to maintain a constant, controlled temperature, ensuring a safe environment for newborns or other patients needing precise thermal regulation.

- Household Appliances: Hairdryers, space heaters, and electric blankets. PTC heaters are common in household products like ceramic space heaters because of their ability to heat quickly and safely. They provide a comfortable heat output while ensuring that the unit does not overheat, protecting users and prolonging the lifespan of the appliance.

- Industrial Equipment: Climate control systems, dehumidifiers, and other equipment requiring precise heat regulation. In industrial applications, PTC heaters are ideal for environments where precise control is required. They are used in dehumidifiers to ensure that moisture is effectively managed without overheating or creating safety hazards.

-

Choosing the Right PTC Heater for Your Needs

When choosing a PTC heater, several factors need to be considered. Determine the required operating temperature, electrical specifications, form factor, and the environment where it will be used. Choosing the right PTC heater tailored to your specific application will maximize its benefits. For instance, if you need a heating element for a high-humidity environment, you would select a PTC heater that is specifically designed to resist moisture and ensure consistent performance even under challenging conditions.

Factors to Consider

To make the most informed decision, consider the following aspects:

- Operating Temperature: Define the temperature range that the PTC heater will need to operate within. PTC heaters are available in a variety of temperature ratings, allowing you to choose one that meets your exact requirements.

- Form Factor: PTC heat comes in different sizes and shapes, making it suitable for a wide range of applications. Consider the physical dimensions and installation requirements to ensure proper integration into your system.

- Electrical Specifications: Voltage and current ratings are essential to match the PTC heaters with your system's power supply. Always verify compatibility to avoid any potential electrical issues.

- Environmental Conditions: If the heater will be used in extreme conditions—such as high humidity or exposure to chemicals—select a PTC heater designed to withstand those conditions to ensure reliable performance over time.

Why Are PTC Heaters Considered Energy Efficient?

One of the most significant advantages of PTC heaters is their energy efficiency. But what exactly makes them so efficient compared to traditional heating technologies? The key lies in their ability to self-regulate. Traditional heaters often require external thermostats to control temperature, which can be inefficient and lead to wasted energy. In contrast, a PTC heater adjusts its power consumption dynamically. When the heater approaches its target temperature, the resistance of the ceramic material increases, reducing the flow of electrical current and thereby reducing energy usage.

Energy Efficiency in Practice

Consider a typical use case involving a space heater. Traditional space heaters will continue consuming the same amount of energy regardless of the ambient temperature, leading to overheating and increased energy costs. On the other hand, a PTC heater used in a space heater will automatically adjust its energy consumption as the room reaches the desired temperature, maintaining warmth efficiently without unnecessary power use. This approach can lead to significant energy savings over time, making PTC heaters a cost-effective solution for both residential and commercial use.

Safety Features of PTC Heaters

When it comes to heating devices, safety is always a top concern. PTC heaters offer multiple safety benefits that make them preferable over traditional heating elements. The primary safety feature of a PTC heater is its self-regulating capability, which ensures that the heater will not exceed its maximum temperature.

Preventing Overheating

One of the most common dangers with traditional heating elements is overheating, which can lead to equipment damage or even fire hazards. Since PTC heaters increase in resistance as they heat up, they naturally limit the amount of current flowing through them, thereby reducing the risk of overheating. This built-in safety mechanism is particularly beneficial in environments where equipment must run continuously without supervision.

Application-Specific Safety

In medical applications, for example, maintaining a stable temperature is crucial. A PTC heater in an incubator can ensure that the temperature remains within safe limits without the need for constant monitoring or adjustment. This makes PTC heaters a trusted component in healthcare settings where reliability and safety are paramount.

Durability and Low Maintenance of PTC Heaters

The design simplicity of PTC heater is one of their most attractive features. Without the need for moving parts, mechanical switches, or complicated electronic circuits, PTC heaters are less susceptible to wear and tear. This translates to a longer lifespan and less frequent maintenance compared to traditional heating elements.

Long-Term Reliability of PTC Heaters

Consider industrial applications where equipment downtime can be costly. PTC heaters provide a solution that minimizes maintenance needs and reduces the risk of unexpected failures. Their robust design ensures that they can withstand demanding conditions, making them suitable for industries such as manufacturing and processing, where reliable, uninterrupted heating is essential.

Versatility of PTC Heaters in Different Industries

The versatility of PTC heaters is unmatched. They are used across a variety of industries, each with unique heating requirements. Their adaptability to different environments makes them an ideal choice for applications that require precise and reliable heating control.

Automotive Applications

In the automotive industry, PTC heaters are commonly used for heating car seats, steering wheels, and defogging windows. These heaters provide rapid heat and are able to maintain consistent warmth without overheating, ensuring comfort and safety for drivers and passengers. The automotive industry's reliance on PTC heater is a testament to their effectiveness in environments where temperature control is crucial.

PTC Heater used for Household Appliances

Many household appliances incorporate PTC heaters because of their safety and efficiency. For instance, ceramic space heater uses PTC elements to quickly heat a room while ensuring that the unit doesn't become dangerously hot. Electric blankets are another example where PTC heater is preferred due to their ability to regulate heat and prevent overheating, providing both safety and comfort to users.

Industrial Equipment

In industrial settings, PTC heaters are used in various types of machinery that require precise temperature control. For example, dehumidifiers and climate control systems rely on PTC heater to maintain optimal operating conditions without the risk of overheating. The reliability of PTC heating element in industrial applications reduces maintenance costs and ensures consistent performance.

Choosing the Right PTC Heater: Practical Tips

To fully benefit from PTC heater, it is important to select the right type for your application. Not all PTC heating elements are created equal, and understanding the specific needs of your application will help in making the best choice. Here are some practical tips to help you choose the right PTC heater:

Understand Your Heating Requirements

The first step in selecting a PTC heater is to clearly define your heating requirements. Are you looking for rapid heat-up time? Do you need a consistent temperature over long periods? Answering these questions will help you narrow down the options and find a PTC heater that meets your needs.

Match Electrical Specifications

Ensuring that the PTC heater matches the electrical specifications of your system is crucial. Check the voltage and current ratings to ensure compatibility. This will not only improve performance but also enhance the safety and longevity of the heater.

FAQs about PTC Heater

Q1: What is a PTC heater, and are they eco-friendly?

PTC heaters are eco-friendly due to their energy-efficient design. By reducing power consumption, they lower greenhouse gas emissions compared to traditional heaters. Their self-regulating feature means they use only the energy needed, reducing waste.

Q2: Do PTC heaters require regular maintenance?

PTC heaters have low maintenance needs. Their simple and robust design reduces the risk of failure. This means fewer service requirements, making them ideal for applications needing minimal maintenance.

Q3: Can PTC heater operate in high-humidity environments?

Yes, PTC heater works well in high-humidity conditions. Their resistance to moisture makes them reliable in areas like bathrooms or dehumidifiers. Their robust design ensures efficiency without moisture-related failures.

Q4: How do PTC heaters compare to traditional heating elements?

PTC heaters are safer and more energy-efficient than traditional elements. Traditional heaters can overheat, posing safety risks. PTC heater self-regulates, maintaining a safe temperature, making it a better choice for many uses.

Conclusion: The Future of PTC Heater is Here

Understanding what is a PTC heater reveals its potential in modern heating. PTC heaters offer energy efficiency, safety, and versatility, making them ideal for various uses. Their minimal maintenance and superior performance make PTC heater an outstanding choice for temperature control. Whether for industrial, automotive, or home use, PTC heaters redefine heating technology. Embrace the power of PTC technology for efficient and sustainable heating solutions.

Contact Us to Learn More About PTC Heaters

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

Logistics

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Shipment

1)Small order quantity and small packing:cargo may be arranged by courier;

2)Bulk order and big volume:shipment may be arranged by sea or by air as per customer’s requirements on FOB, C&F,CIF or LCL terms and do prompt shipment which is very important for our customers, so we do this matter seriously and we may arrange our shipment in time due to our rich experiences in this line. We may also accept the shipment on the term of freight prepaid or freight collect.

You may also like

PTC Heater Element : Key Features, Applications, and Benefits

PTC Heaters: Efficient Heating with Ceramic Heating Elements

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd