Market Demand Drives Technical Advances in Thermal Resistors

Discover how DXM is at the forefront of innovation in the field of thermal resistors, driven by evolving market demands. Our latest article explores how advancements in PTC Thermistors and NTC Thermistors are revolutionizing industries by enhancing reliability and efficiency. Learn how DXM's dedication to cutting-edge technology is meeting global needs, setting us apart as industry leaders. Stay informed on the critical trends shaping the future of thermal resistor and transforming technology landscapes.

- Market-Driven Advancements in Thermal Resistors

- Understanding Thermal Resistors: An Overview

- The Influence of Market Demand on Thermal Resistor Development

- Evolving PTC Thermistors and NTC Thermistors for Modern Consumer Electronics

- Thermal Resistors in EV Safety and Performance

- Advancements in PTC Thermistors and NTC Thermistors

- Enhanced Safety Features with PTC Thermistors and NTC Thermistors

- Energy Efficiency and Cost-Effectiveness in PTC Thermistors

- Strategic Innovations in Thermal Resistors Manufacturing

- Emerging Trends in PTC Thermistors and NTC Thermistors Technology

- Challenges of Thermal Resistors in Meeting Market Demands

- Conclusion: The Symbiotic Relationship Between Market Demand and Innovation

- Frequently Asked Questions (FAQs)

Market-Driven Advancements in Thermal Resistors

The rapid evolution of electronic devices has accelerated the advancement of thermal resistors, including PTC Thermistors and NTC Thermistors. These components are vital for efficient thermal management in modern technology, with their innovations largely propelled by increasing market demand.

As electronic devices evolve, thermal resistors, particularly PTC and NTC Thermistors, have become indispensable. These components ensure safety and efficiency, with market dynamics playing a crucial role in driving their continuous improvement.

Understanding Thermal Resistors: An Overview

Thermal resistor is essential components in modern electronics, providing critical thermal management for device safety and efficiency. Positioned at the forefront of temperature regulation, thermal resistors adjust to temperature changes, ensuring the prevention of overheating,overcurrent and overload.

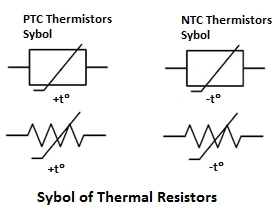

The two primary types—NTC Thermistors and PTC Thermistors—serve different roles across various applications, from household appliances to automotive systems.

-

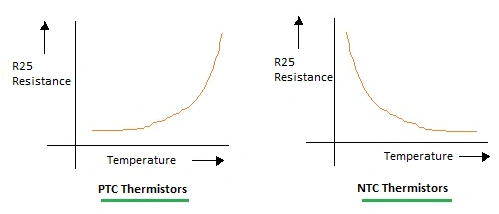

NTC Thermistors: Resistance decreases with rising temperatures, making them ideal for accurate temperature control and measurement.

-

PTC Thermistors: Resistance increases with temperature, providing self-regulating features perfect for overcurrent protection and thermal management.

The Influence of Market Demand on Thermal Resistor Development

Evolving PTC Thermistors and NTC Thermistors for Modern Consumer Electronics

The growing demand for thermal resistors in smarter, more compact, and energy-efficient consumer electronics is undeniable. Thermal resistors, including PTC Thermistors and NTC Thermistors, are crucial for precise thermal regulation. As devices like smartphones, laptops, and wearables become more complex, the need for advanced thermal management intensifies, driving continuous innovation in PTC and NTC Thermistors.

Thermal Resistors in EV Safety and Performance

PTC Thermistors and NTC Thermistors are critical in the automotive industry's shift to electric vehicles (EVs). Effective thermal management relies heavily on PTC Thermistors and NTC Thermistors. These components are essential in battery management systems, ensuring both performance and safety. As automotive designs evolve and safety standards tighten, the demand for reliable thermal resistors continues to grow.

Advancements in PTC Thermistors and NTC Thermistors

Enhanced Safety Features with PTC Thermistors and NTC Thermistors

Thermal resistors, including PTC Thermistors and NTC Thermistors, have advanced significantly due to rising market demand. PTC Thermistor and NTC Thermistor are now crucial in safety applications, as they self-regulate resistance with temperature increases, reducing the risk of overheating and fire.

Energy Efficiency and Cost-Effectiveness in PTC Thermistors

As energy costs rise, the demand for efficient solutions grows. PTC Thermistors and NTC Thermistors now offer improved energy efficiency and cost-effectiveness, making them ideal for industrial and consumer electronics.

Strategic Innovations in Thermal Resistors Manufacturing

Precision Manufacturing Through Automation

To meet the demand for consistent and high-quality thermal resistor, manufacturers are turning to automation. This ensures precision in large-scale production, reducing errors and increasing component reliability.

Environmentally Friendly Production Techniques

Sustainability is driving change in manufacturing processes for thermal resistors. Manufacturers are now adopting eco-friendly materials and methods, aiming to lower the carbon footprint and support global sustainability goals.

Emerging Trends in PTC Thermistors and NTC Thermistors Technology

IoT-Enabled Applications

The expansion of the Internet of Things (IoT) is creating new opportunities for thermal resistor. IoT devices increasingly demand effective thermal management, driving advancements in PTC Thermistors and NTC Thermistors to enhance their fabrication and functionality.

Innovations in PTC Thermistors and NTC Thermistors for Wearable Technology

Wearable technology is a rapidly growing field, pushing innovation in thermal resistors, particularly PTC Thermistors and NTC Thermistors. As these devices become integral to daily life, efficient heat management is crucial, leading to continuous refinement in thermistor designs.

Challenges of Thermal Resistors in Meeting Market Demands

Rapid Technological Changes

Keeping pace with rapid advancements presents a formidable challenge for manufacturers. Constant innovation is required to meet evolving consumer expectations and support new applications in cutting-edge technologies.

Supply Chain Constraints

Global supply chain issues, exacerbated by recent geopolitical tensions and the lingering effects of the COVID-19 pandemic, pose significant challenges. Ensuring timely availability of raw materials, along with maintaining quality control, is critical for sustaining the momentum in thermal resistor advancements.

Conclusion: The Symbiotic Relationship Between Market Demand and Innovation

The symbiotic relationship between market demand and technological innovation in thermal resistor is evident in the myriad of advanced applications emerging today. PTC thermistor and other thermal resistors are undergoing near-constant upgrades to meet the ever-growing needs of various industries. As consumer requirements continue to evolve, so too will the innovations that drive the thermal resistor markets forward, ensuring these components remain at the forefront of technological development.

Frequently Asked Questions (FAQs)

1. What are thermal resistors used for?

Thermal resistors are used to manage and regulate heat in electronic devices, ensuring safety and efficiency.

2. How does PTC thermistor work?

PTC thermistor increases their resistance as temperature rises, preventing overheating in electronic circuits.

3. Why is market demand crucial for thermal resistor technology?

Market demand drives innovation and advancements in PTC Thermistor and NTC Thermistor, pushing for enhanced functionality and efficiency.

4. How do advancements in thermal resistors impact consumers?

They provide safer, more reliable, and energy-efficient electronic devices, improving the overall user experience.

5. What industries benefit the most from thermal resistor innovations?

Consumer electronics, automotive, and wearable technology industries significantly benefit from advancements in thermal resistor.

In conclusion, the robust demand across various sectors underscores the importance of continuous innovation in PTC Thermistors and NTC Thermistors. As the market evolves, so too will the technology, ensuring that thermal resistors remain indispensable components across industries.

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

Price and Payment

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

You may also like

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Termistor PTC Thermistors MZ21 Series: Reliable Protection for Telecom Main Distribution Frame

PTC Electric Thermistors for telecom apparatus circuit protection (MZ23 series)

PTC Electronics MZ31 Series MZ8 Type: Reliable Overcurrent and Overload Protection Solutions

Negative Temperature Coefficient Thermistor for temperature compensation (MF11 series)

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd