Hot Water Temperature Sensors: Guide for Professionals

Explore the world of hot water temperature sensors! Learn about their types, applications, selection, and maintenance for optimal performance.

- Understanding the Importance of Water Temperature Sensors

- Why Accurate Hot Water Temperature Sensing Matters

- Types of Water Temperature Sensors

- Key Applications of Hot Water Temperature Sensors

- Selecting the Right Hot Water Temperature Sensor

- Installation and Maintenance Best Practices

- Advantages of NTC Thermistors in Hot Water Applications

- The Future of Hot Water Temperature Sensor Technology

- DXM: Your Partner in Temperature Sensing Solutions

- FAQs About Hot Water Temperature Sensors

- Q: What is the difference between a thermistor and an RTD?

- Q: How do I choose the right water temperature sensor?

- Q: How often should I calibrate my water temperature sensor?

- Q: What are the common causes of water temperature sensor failure?

- Q: Can water temperature sensors be used in corrosive environments?

- Conclusion

Understanding the Importance of Water Temperature Sensors

Water temperature sensors are vital for accuracy and efficiency across various industries. A hot water temperature sensor ensures the safety and performance of home appliances and industrial systems. With over 28 years of experience, DXM specializes in these sensors, delivering precision where it matters most. From household use to complex machinery, our sensors optimize operations and prevent overheating. Reliable temperature monitoring is crucial for both safety and energy efficiency.

Let us help you choose the right water temperature sensors for your needs.

Why Accurate Hot Water Temperature Sensing Matters

Precise temperature measurement is crucial for several reasons:

* Safety: Prevents scalding in residential and commercial hot water systems.

* Efficiency: Optimizes energy consumption in water heaters and industrial processes.

* Performance: Ensures consistent and reliable operation of equipment.

* Regulation: Complies with industry standards and safety regulations.

* Quality Control: Maintains product quality in manufacturing processes.

Types of Water Temperature Sensors

A variety of water temperature sensors cater to different needs. Here’s a breakdown of the most common types:

1. Thermistors: These are semiconductor devices whose resistance changes significantly with temperature. They are highly sensitive and come in two types:

* NTC (Negative Temperature Coefficient) Thermistors: Resistance decreases as temperature increases. Ideal for applications requiring high sensitivity, like hot water temperature sensors.

* PTC (Positive Temperature Coefficient) Thermistors: Resistance increases as temperature increases. Often used for over-temperature protection.

2. Resistance Temperature Detectors (RTDs): These sensors utilize the change in electrical resistance of a metal, typically platinum, to measure temperature. RTDs are known for their accuracy and stability over a wide temperature range. This includes PT100 temperature sensor, PT1000 temperature sensor, PT100 smd, PT1000 smd and more.

3. Thermocouples: These sensors consist of two dissimilar metal wires joined at one end. The temperature difference between the junction and a reference point creates a voltage that can be measured and correlated to temperature. Thermocouples are robust and can withstand high temperatures.

4. Integrated Circuit (IC) Sensors: These sensors integrate temperature sensing circuitry into a single chip, providing a digital or analog output proportional to temperature. IC sensors are compact and easy to use.

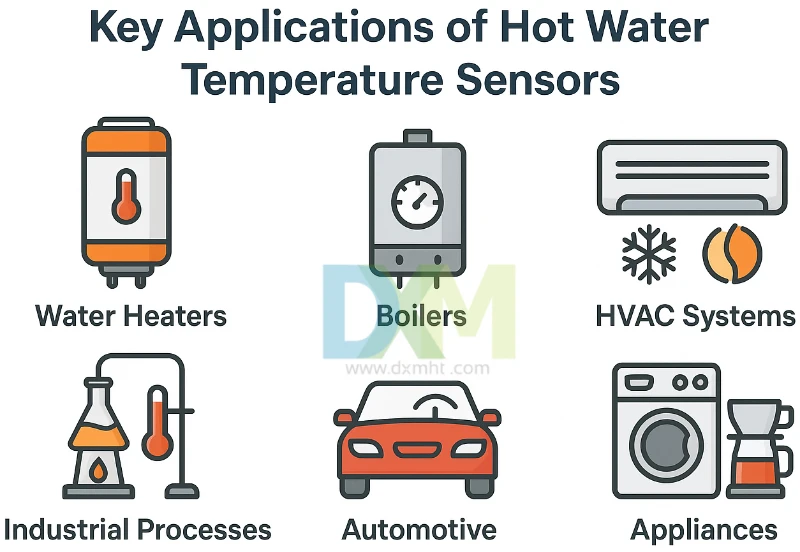

Key Applications of Hot Water Temperature Sensors

Hot water temperature sensors are essential across numerous sectors:

* Water Heaters: Regulating water temperature to prevent overheating and scalding.

* Boilers: Monitoring and controlling water temperature for efficient heating.

* HVAC Systems: Ensuring optimal performance of heating and cooling systems.

* Industrial Processes: Maintaining precise temperature control in chemical, pharmaceutical, and food processing industries.

* Automotive: Monitoring engine coolant temperature.

* Appliances: Controlling water temperature in dishwashers, washing machines, and coffee makers.

Selecting the Right Hot Water Temperature Sensor

Choosing the correct water temperature sensor, and specifically a hot water temperature sensor, requires careful consideration of several factors:

1. Temperature Range: Ensure the sensor can accurately measure the expected temperature range of the application.

2. Accuracy: Determine the required accuracy for the application. RTDs generally offer higher accuracy than thermistors, while thermocouples are suitable for high-temperature applications where moderate accuracy is acceptable.

3. Response Time: Consider how quickly the sensor needs to respond to temperature changes. Thermistors typically have faster response times than RTDs.

4. Stability: Evaluate the long-term stability of the sensor. RTDs are known for their excellent stability.

5. Environmental Conditions: Select a sensor that can withstand the environmental conditions of the application, such as humidity, vibration, and chemical exposure.

6. Output Signal: Choose a sensor with an output signal that is compatible with the control system. Common output signals include analog voltage, analog current, and digital signals.

7. Cost: Balance performance requirements with budget constraints. Thermistors are generally more cost-effective than RTDs.

Installation and Maintenance Best Practices

Proper installation and maintenance are vital for ensuring accurate and reliable performance of water temperature sensors, including hot water temperature sensors:

* Proper Placement: Position the sensor in a location that accurately represents the water temperature. Avoid areas with stagnant water or direct sunlight.

* Secure Mounting: Ensure the sensor is securely mounted to prevent movement and ensure good thermal contact with the water.

* Wiring: Use appropriate wiring and connectors to minimize signal loss and interference.

* Calibration: Periodically calibrate the sensor to maintain accuracy.

* Cleaning: Clean the sensor regularly to remove any build-up of scale or debris.

* Inspection: Inspect the sensor for damage or corrosion. Replace the sensor if necessary.

Advantages of NTC Thermistors in Hot Water Applications

NTC thermistors stand out as an excellent choice for hot water temperature sensor applications due to their unique properties:

* High Sensitivity: NTC thermistors exhibit a large change in resistance for small temperature changes, enabling precise temperature measurement.

* Fast Response Time: Their small size and low thermal mass allow for quick response to temperature variations.

* Cost-Effectiveness: NTC thermistors are generally more affordable than RTDs and thermocouples.

* Versatility: Available in a wide range of resistance values and package sizes to suit various applications.

The Future of Hot Water Temperature Sensor Technology

Advancements in sensor technology continue to improve the performance and capabilities of water temperature sensors. Key trends include:

* Miniaturization: Smaller sensors with enhanced performance are enabling new applications.

* Wireless Connectivity: Wireless sensors are simplifying installation and reducing wiring costs.

* Smart Sensors: Sensors with built-in processing capabilities are providing more advanced data analysis and control.

* Improved Accuracy and Stability: Ongoing research and development are leading to sensors with even higher accuracy and long-term stability.

DXM: Your Partner in Temperature Sensing Solutions

At DXM, we pride ourselves on providing high-quality water temperature sensors, including specialized hot water temperature sensors, for a wide range of applications. With our 29 years of experience, ISO 9001:2008 certification, and strong R&D capabilities, we are committed to delivering innovative and reliable temperature sensing solutions. Our product line includes a comprehensive selection of thermistors (PTC Thermistor, NTC Thermistor), RTDs (PT100 temperature sensor, PT1000 temperature sensor, PT100 smd, PT1000 smd), and other temperature sensing components.

FAQs About Hot Water Temperature Sensors

Q: What is the difference between a thermistor and an RTD?

A: Thermistors are semiconductor devices whose resistance changes with temperature. RTDs measure temperature based on the change in resistance of a metal. Thermistors are more sensitive, while RTDs are more accurate and stable. Water temperature sensors often utilize both.

Q: How do I choose the right water temperature sensor?

A: Consider the temperature range, accuracy, response time, environmental conditions, and output signal requirements of the application.

Q: How often should I calibrate my water temperature sensor?

A: Calibration frequency depends on the application and sensor type. It is generally recommended to calibrate sensors annually or as needed based on performance monitoring.

Q: What are the common causes of water temperature sensor failure?

A: Common causes include corrosion, physical damage, and exposure to extreme temperatures.

Q: Can water temperature sensors be used in corrosive environments?

A: Yes, but it is important to select a sensor with appropriate materials and protective coatings to withstand the corrosive environment.

Conclusion

Hot water temperature sensors are critical components in various applications, ensuring safety, efficiency, and optimal performance. By understanding the different types of sensors, selection criteria, and best practices for installation and maintenance, you can choose the right sensor for your specific needs and ensure its reliable operation.

Ready to enhance your systems with precise and reliable temperature sensing? Contact us today to explore our wide range of water temperature sensors and hot water temperature sensors! Benefit from our industry expertise and cutting-edge technology to optimize your applications.

Explore the advantage of using water temperature sensors or hot water temperature sensors.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Price and Payment

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Logistics

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

You may also like

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd