Probe Temperature Sensor & Temp Sensor Types: A Practical Guide

Explore probe temperature sensor types (NTC, RTD, thermocouple) and their applications. Learn about accuracy, range, and selection for optimal temperature sensing.

- Decoding Temperature: A Deep Dive into Probe Temperature Sensor and Temp Sensor Types

- What is Probe Temperature Sensor?

- Why Use a Probe Temperature Sensor?

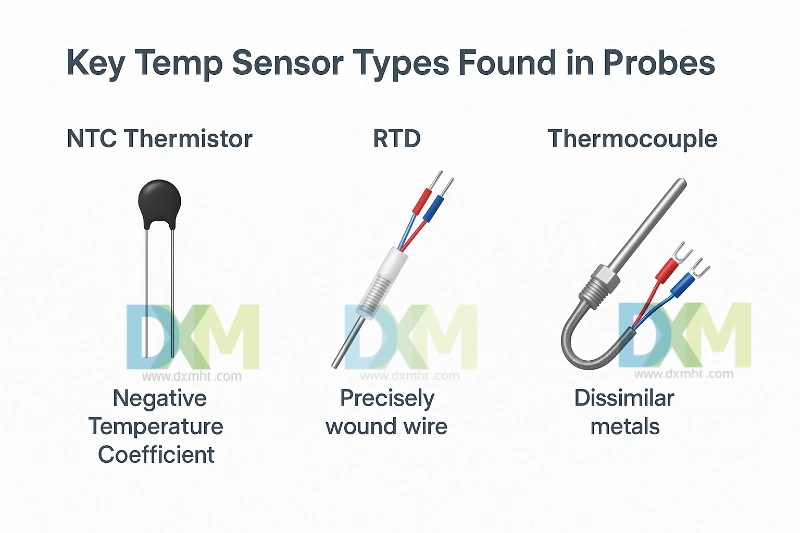

- Key Temp Sensor Types Found in Probes

- 1. NTC Thermistors:

- 2. Resistance Temperature Detectors (RTDs):

- 3. Thermocouples:

- Selecting the Right Probe Temperature Sensor: Key Considerations

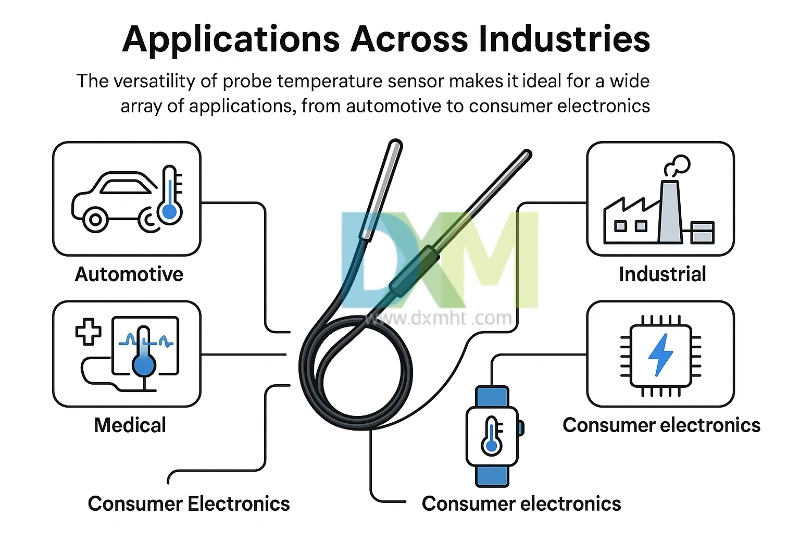

- Applications Across Industries

- Benefits of Partnering with DXM for Your Probe Temperature Sensor Needs

- Common Problems and Troubleshooting

- Future Trends in Temperature Sensing

- Conclusion of Probe Temperature Sensor

- Call to Action:

Decoding Temperature: A Deep Dive into Probe Temperature Sensor and Temp Sensor Types

Welcome, fellow thermistor enthusiasts! At DXM, with over 29 years of expertise as a leading modernization electronics manufacturer, we understand the critical role probe temperature sensors and various temp sensor types play across countless industries. Today, let’s delve into the fascinating world of these essential components, exploring their functionality, types, selection criteria, and best-use practices.

What is Probe Temperature Sensor?

Simply put, a probe temperature sensor is a temperature sensing device encased within a protective housing or probe. This design allows the sensor to be inserted into various environments – liquids, gases, solids – for accurate temperature measurement without exposing the sensitive sensing element to harsh conditions. They are crucial for applications requiring precise and reliable temperature data.

Why Use a Probe Temperature Sensor?

Probe temperature sensor offers several advantages over bare sensors:

* Protection: The probe shields the sensor from physical damage, corrosion, and contamination.

* Durability: Increased lifespan in demanding environments.

* Ease of Use: Simplified installation and replacement.

* Versatility: Suitable for a wide range of applications and media.

* Accuracy: Provides accurate readings in a variety of conditions.

Key Temp Sensor Types Found in Probes

Several temp sensor types are commonly integrated into probe assemblies. Let's explore the most prevalent:

1. NTC Thermistors:

NTC (Negative Temperature Coefficient) thermistors are resistors whose resistance decreases as temperature increases.

* How They Work: They rely on the principle that the resistance of a semiconductor material changes predictably with temperature.

* Pros: High sensitivity, fast response time, cost-effective, small size.

* Cons: Non-linear response (requires linearization), limited temperature range compared to other types.

* Typical Applications: Consumer electronics, HVAC systems, battery temperature monitoring, automotive applications.

DXM specializes in high-quality NTC thermistors perfect for precise temperature control.

The sensitivity of NTC thermistors makes them ideal for detecting even slight changes in temperature, crucial for applications requiring precise control.

2. Resistance Temperature Detectors (RTDs):

RTDs are temperature sensors that utilize the principle that the electrical resistance of a metal changes predictably with temperature.

* How They Work: A precisely wound wire (typically platinum, PT100, PT1000) changes resistance linearly with temperature.

* Pros: High accuracy, excellent stability, linear response, wide temperature range.

* Cons: Slower response time compared to thermistors, more expensive.

* Typical Applications: Industrial temperature monitoring, laboratory equipment, process control, aerospace.

DXM offers a range of RTD sensors, including PT100 and PT1000, for demanding industrial applications.

*RTDs, particularly PT100 and PT1000 probe temperature sensor, are known for their stability and are essential in industrial settings where accuracy is paramount.

3. Thermocouples:

Thermocouples are formed when two dissimilar metals are joined, creating a voltage that varies with temperature.

* How They Work: The Seebeck effect generates a voltage proportional to the temperature difference between the junctions of two different metals.

* Pros: Wide temperature range (can measure extremely high temperatures), robust, relatively inexpensive.

* Cons: Lower accuracy compared to RTDs, requires cold-junction compensation, non-linear response.

* Typical Applications: High-temperature furnaces, engine exhaust monitoring, process control, metalworking.

In high-temperature environments where other temp sensor types may fail, thermocouples excel due to their robust design.

Selecting the Right Probe Temperature Sensor: Key Considerations

Choosing the optimal probe temperature sensor depends on several factors:

1. Temperature Range: Determine the minimum and maximum temperatures the sensor will encounter.

2. Accuracy Requirements: How precise does the temperature measurement need to be?

3. Response Time: How quickly does the sensor need to react to temperature changes?

4. Environmental Conditions: Consider factors like humidity, corrosive substances, and vibration.

5. Probe Material: Select a probe material compatible with the measured medium (e.g., stainless steel for liquids, specialized coatings for corrosive environments).

6. Sensor Type: Evaluate the pros and cons of each probe temperature sensor type (NTC thermistor, RTD, thermocouple) based on the application requirements.

7. Budget: Balance performance requirements with cost considerations.

8. Keyword Embedding: When selecting a probe temperature sensor, carefully consider the environmental conditions to ensure longevity and accurate readings.

Applications Across Industries

Probe temperature sensors are indispensable in numerous industries:

* Automotive: Engine temperature monitoring, climate control, battery management.DXM supplies reliable sensors for automotive applications, ensuring optimal performance and safety.

* HVAC: Air temperature control, refrigerant monitoring, boiler temperature regulation.

* Industrial: Process control, equipment monitoring, food processing, chemical processing.Our industrial-grade sensors withstand harsh environments.

* Medical: Patient monitoring, laboratory equipment, sterilization processes.

* Consumer Electronics: Temperature control in appliances, wearables, and other devices. Our compact thermistors are ideal for consumer applications.

* Power Electronics: Protecting electronic components from overheating.

Keyword Embedding: The versatility of probe temperature sensors makes them ideal for a wide array of applications, from automotive to consumer electronics.

Benefits of Partnering with DXM for Your Probe Temperature Sensor Needs

As an ISO 9001:2008-certified manufacturer, DXM offers:

* High-Quality Products: Reliable and accurate probe temperature sensor solutions.

* Extensive Product Range: A wide selection of NTC thermistors, RTDs, and other temperature sensors to suit diverse applications.

* Customization Options: Tailored sensors designs to meet specific requirements.

* Expert Technical Support: Our experienced engineers provide guidance and assistance in selecting the right sensors for your application.

* Competitive Pricing: Cost-effective solutions without compromising quality.

* Keyword Embedding: DXM's commitment to quality ensures that our temp sensor types and probe temperature sensor solutions meet the highest standards.

Common Problems and Troubleshooting

While probe temperature sensors are generally reliable, some common issues can arise:

* Inaccurate Readings: Caused by sensors damage, calibration drift, or incorrect wiring.

* Slow Response Time: Can be due to poor thermal contact or sensors aging.

* Signal Noise: Interference from electrical sources can affect accuracy.

* Sensor Failure: Overheating, corrosion, or physical damage can lead to sensors failure.

Troubleshooting tips include:

* Verifying sensors wiring and connections.

* Calibrating the sensors regularly.

* Ensuring good thermal contact between the sensor and the measured object.

* Shielding sensor cables from electrical noise.

* Replacing damaged or faulty sensors.

Future Trends in Temperature Sensing

The field of temperature sensing is constantly evolving. Some emerging trends include:

* Miniaturization: Smaller, more compact sensors for use in portable devices and embedded systems.

* Wireless Sensors: Wireless temperature sensors for remote monitoring and data logging.

* Smart Sensors: Sensors with integrated processing capabilities for advanced data analysis and control.

* High-Temperature Sensors: Sensors capable of withstanding extremely high temperatures for applications in aerospace and industrial processes.

Conclusion of Probe Temperature Sensor

Probe temperature sensor is vital component in a multitude of applications, offering accurate, reliable, and durable temperature measurement solutions. Understanding the different temp sensor types, their characteristics, and selection criteria is crucial for optimizing performance and ensuring accurate results. At DXM, we are committed to providing our customers with high-quality temperature sensing solutions and expert technical support.

Call to Action:

Ready to optimize your temperature sensing capabilities? Contact DXM today to explore our wide range of probe temperature sensor and temp sensor types. Let us help you find the perfect solution for your specific application. Explore our product catalog and request a quote today! We're here to provide quality thermistor, varistor, high voltage capacitor, ceramic disc capacitor, temperature sensor., thermometer sensor, rtd sensor, and PTC heater.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

Price and Payment

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Logistics

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

You may also like

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd