What Are NTC Thermistors Made Of ? Discover the Secrets

Learn about the composition of thermistors NTC, including key metal oxides (MnO2, NiO, CoO, CuO), binding agents, and manufacturing processes. Understand how composition affects performance characteristics like temperature coefficient and stability. Choose the right thermistor for your application!

- What Are NTC Thermistors Made Of? A Deep Dive into Thermistors NTC Composition

- The Core Material of Thermistors NTC: Metal Oxides

- The Binding Agent and Manufacturing Process of Thermistors NTC

- Different Types and Variations in Composition

- Understanding the Implications of Composition

- Frequently Asked Questions (FAQs)

- Q: Are all thermistors NTC made of the same materials?

- Q: How does the composition affect the accuracy of the NTC thermistor?

- Q: What are the environmental factors that affect NTC thermistor performance?

- Conclusion

What Are NTC Thermistors Made Of? A Deep Dive into Thermistors NTC Composition

Understanding the materials used in the manufacturing of thermistors NTC is crucial for anyone working with these temperature-sensing devices. In this article, we'll explore the composition of thermistors NTC , focusing on precisely what are NTC thermistors made of. We’ll delve into the key components and their roles in determining the thermistor's characteristics.

The Core Material of Thermistors NTC: Metal Oxides

The heart of an NTC thermistor lies in its semiconducting material. This material is typically a blend of various metal oxides, carefully chosen and precisely proportioned to achieve the desired temperature-resistance characteristics. Common metal oxides used in thermistors NTC , what are NTC thermistors made of, include:

* Manganese Oxide (MnO2): This is often the primary component, contributing significantly to the thermistor's overall resistance. The precise amount of MnO2 significantly impacts the NTC thermistor's sensitivity and temperature coefficient.

* Nickel Oxide (NiO): Nickel oxide plays a crucial role in modifying the electrical properties of the thermistor. It interacts with other oxides to fine-tune the overall resistance-temperature curve.

* Cobalt Oxide (CoO): The inclusion of cobalt oxide helps adjust the B-constant (a critical parameter defining the thermistor's temperature sensitivity) and fine-tune the overall temperature response.

* Copper Oxide (CuO): In certain formulations, copper oxide is added to further tailor the resistance-temperature characteristics, potentially improving linearity or stability over a specific temperature range.

* Other Additives: Depending on the desired performance, other metal oxides or minor additives may be incorporated into the mix. These can enhance factors such as long-term stability, lifespan, and overall reliability of the thermistors NTC. These additives address factors like aging and reducing noise in the thermistor response.

The precise ratios of these metal oxides are carefully controlled during manufacturing. Slight variations in these ratios can significantly impact the final characteristics of the thermistor NTC, directly influencing what are NTC thermistors made of, specifically the temperature coefficient, resistance value, and overall performance.

The Binding Agent and Manufacturing Process of Thermistors NTC

The metal oxide mixture isn't simply pressed together; it requires a binding agent to create a cohesive structure. This binding agent usually consists of a ceramic material, such as alumina (Al2O3), that bonds the metal oxide grains together, forming a solid, stable structure.

The manufacturing process typically involves mixing the metal oxides and binding agent, forming a paste, and then shaping this paste into beads, chips, or other desired forms. Subsequent steps involve firing (sintering) the material at high temperatures to produce a stable and durable structure. This high-temperature sintering process creates a strong, dense ceramic body with the metal oxides evenly distributed and interconnected. This is crucial to ensuring consistent and reliable performance in the final thermistor NTC ; understanding what are NTC thermistors made of is key to appreciating the manufacturing process.

The final steps involve applying leads or other connection points to the thermistor for electrical interfacing. The whole process is tightly controlled to ensure consistency and high quality of the thermistor NTC . What are NTC thermistors made of is directly tied to its performance characteristics, and ensuring high-quality materials and a precise process are essential.

Different Types and Variations in Composition

While the fundamental composition remains similar across different NTC thermistors, variations exist depending on the desired application. For instance, thermistors designed for high-temperature applications may require different metal oxide ratios and binding agents to maintain stability and performance under extreme conditions. Similarly, the application will dictate the choice of lead material and the overall construction of the NTC thermistor.

The precise control over composition is critical in determining the thermistor's behavior. This includes aspects like the sensitivity, accuracy, and long-term stability. Factors influencing the composition of thermistor NTC , and therefore influencing what are NTC thermistors made of, include the target temperature range, required resistance values, linearity requirements, and the overall application environment.

Understanding the Implications of Composition

The composition of an NTC thermistor dictates its performance characteristics. Understanding what are NTC thermistors made of allows for better selection and application of these devices. Factors to consider include:

* Temperature Coefficient (B-Constant): The relationship between resistance and temperature is crucial; it's directly affected by the metal oxide ratios.

* Resistance Value: The base resistance at a specified temperature is set by the composition.

* Linearity: The extent to which the resistance change is linear with temperature.

* Stability: How well the thermistor maintains its characteristics over time and various environmental conditions.

* Power Dissipation: How much power the thermistor can handle without damage.

Precisely controlling the composition of thermistor NTC – knowing what are NTC thermistors made of— allows manufacturers to create devices tailored to specific needs. This precision ensures optimal performance in various applications, from simple temperature monitoring to sophisticated control systems.

Frequently Asked Questions (FAQs)

Q: Are all thermistors NTC made of the same materials?

A: While the core components are typically the same metal oxides, the precise ratios and the addition of other elements vary widely depending on the desired performance characteristics of the thermistors NTC. Understanding what is NTC thermistor made of is key to seeing this diversity.

Q: How does the composition affect the accuracy of the NTC thermistor?

A: The precise control of the metal oxide ratios directly impacts the accuracy of the thermistor’s temperature reading. Slight variations can lead to significant deviations from the desired performance.

Q: What are the environmental factors that affect NTC thermistor performance?

A: Environmental factors such as moisture, temperature extremes, and chemical exposure can all affect the long-term performance of thermistor NTC. The materials used in their construction, however, play a significant role in their resilience. Understanding what are NTC thermistors made of can help predict their behavior in different conditions.

Conclusion

In conclusion, understanding the composition of thermistors NTC— what are NTC thermistors made of —is key to understanding their performance. The careful selection and precise control of metal oxides and binding agents are essential for achieving the desired temperature-resistance characteristics. This detailed knowledge empowers engineers and designers to select the appropriate thermistor for any given application, ensuring optimal performance and reliability. We hope this information has been helpful in clarifying the intricacies of thermistor NTC construction and performance.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Logistics

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Price and Payment

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

You may also like

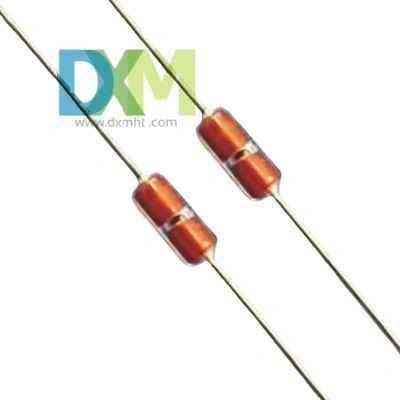

Glass Thermistor MF58 NTC for temperature control

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd